by Meltio | Sep 19, 2023 | Knowledge Base

The use of wire feedstock with a laser energy source in DED has gained momentum in recent years, with increasing research and industrial applications. These features make it a new and promising option in the field of additive manufacturing, generating significant...

by Meltio | Sep 19, 2023 | Knowledge Base

Robot arm 3D printing, also known as robotic 3D printing or robotic additive manufacturing, combines a 3D printer head that extrudes materials with a multi-axis robotic arm, resulting in a highly versatile 3D printer compared to traditional models. The utilization of...

by Meltio | Sep 19, 2023 | Knowledge Base

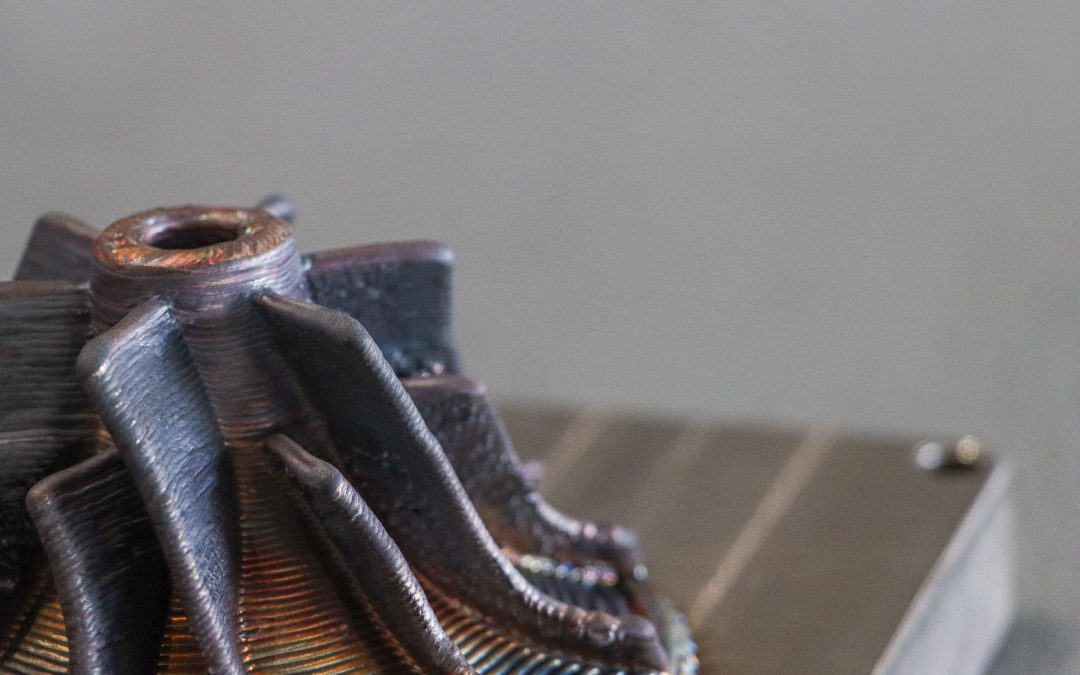

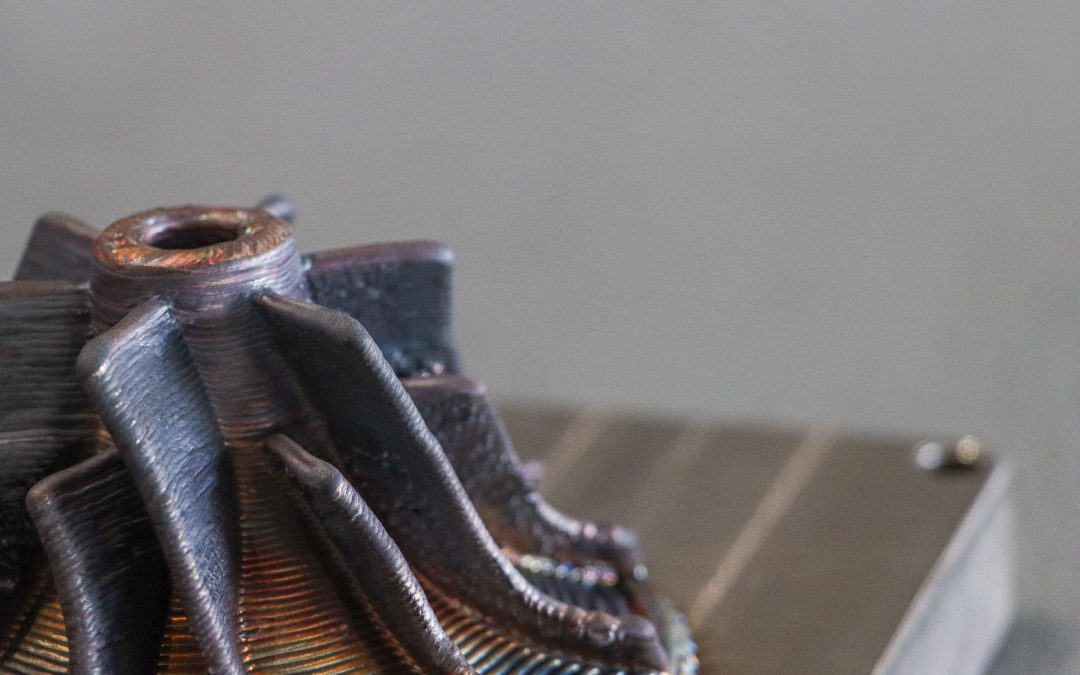

This blog post provides a comprehensive overview of repair strategies for metal additive manufacturing (AM) technology. It explores repair techniques available for Meltio’s technology AM and emphasizes the importance of selecting appropriate repair strategies based on...

by Meltio | Sep 18, 2023 | Knowledge Base

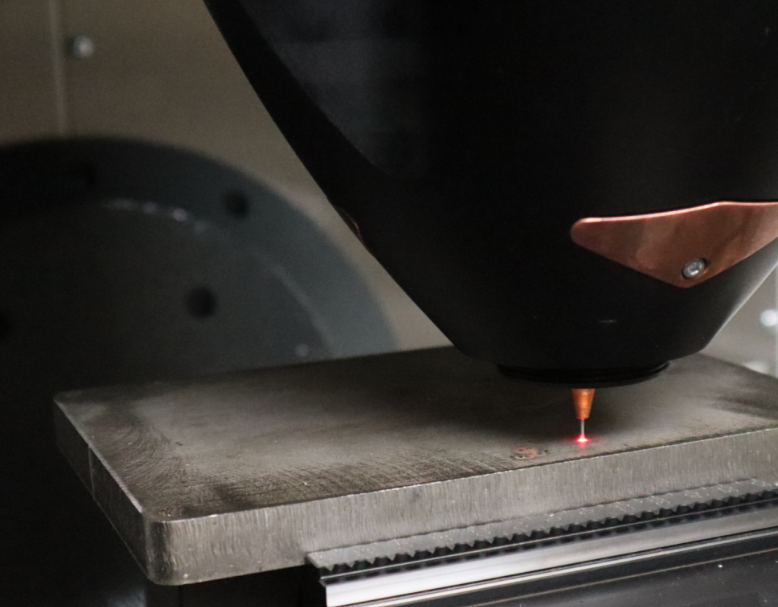

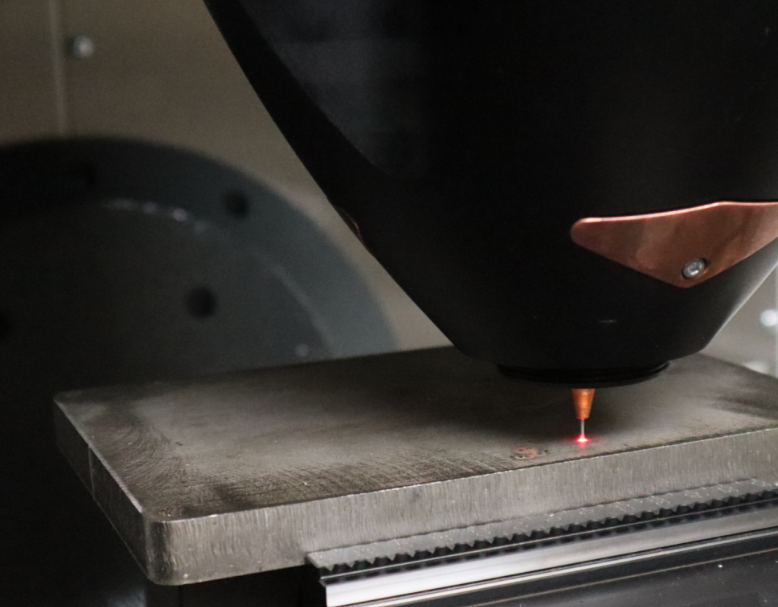

Within the domain of 3D metal printing, specifically in Wire-Laser Directed Energy Deposition (DED), the concept of process control plays a critical role in ensuring optimal printing results. The primary goal is to maintain a delicate energy balance between the...

by Meltio | Sep 18, 2023 | Knowledge Base

This blog post aims to provide an explanation of the concepts of near net shape and over thickness, which are highly relevant to Meltio’s Wire-LMD technology. Additionally, it will offer a concise overview of when, how, and how much over thickness should be...

by Meltio | Sep 6, 2023 | Knowledge Base

Conformal cooling channels refer to cooling channels that are designed to conform to the shape of a part being manufactured and therefore not possible to produce with traditional manufacturing methods. These cooling channels are typically used in molds for polymer...