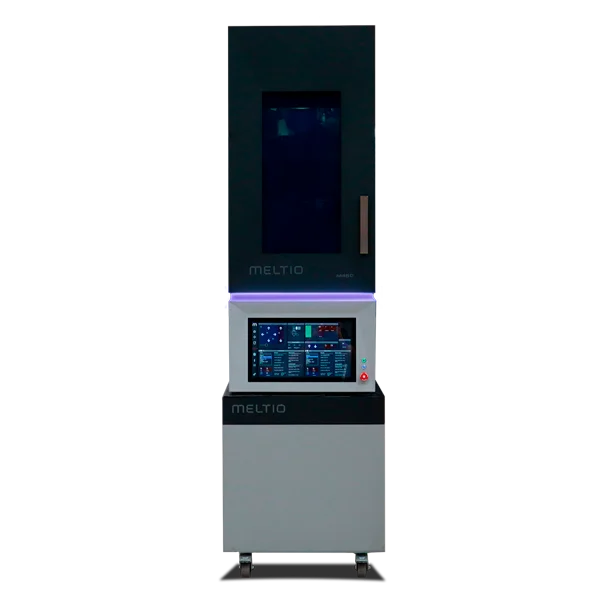

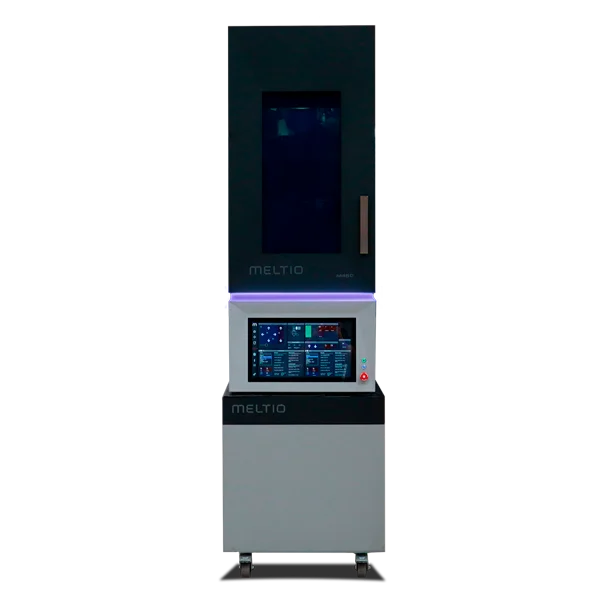

Meltio M450

Turn-key Metal

3D Printer

Designed for industry without the need for industrial infrastructure; affordable, reliable, safe, and easy to use metal 3D printer. Ideal for small to medium size part fabrication, and multi-metal 3D printing research.

The Meltio M450 allows users to produce metal parts of very high density

in a single-step process on a very compact footprint.

Wire-Laser Metal 3D Printer

It allows users to produce metal parts of very high density in a single-step process on a very compact footprint.

Safe

Suitable for any environment thanks to a process built around wire, a sealed chamber and a built-in 3 stage filter.

Easy-to-use

Automatic toolpath generation and material print profiles supplied by Meltio make for a plug and play experience.

Reliable

The metal 3D printing process is monitored in real time and compensated if required by process control.

Affordable

The low capital and running costs of the Meltio M450 make metal 3D printing of conventional parts possible.

Technical Specifications

Dimensions (WxDxH):

560 × 600 × 1400 mm

Print Envelope (WxDxH):

145 x 168 x 390 mm

System Weight:

250 kg

Laser Type:

6 x 200 W direct diode lasers

Laser Wavelength:

976 nm

Power Input:

208/230V Three phase and 400V three phase are compatible

Power Consumption:

2 – 5 kW peak depending on selected options

Process Control:

Closed-loop, laser and wire modulation

Enclosure:

Laser-safe, sealed, controlled atmosphere

Interface:

USB, ethernet, wireless datalink

Cooling:

Active water-cooled chiller included

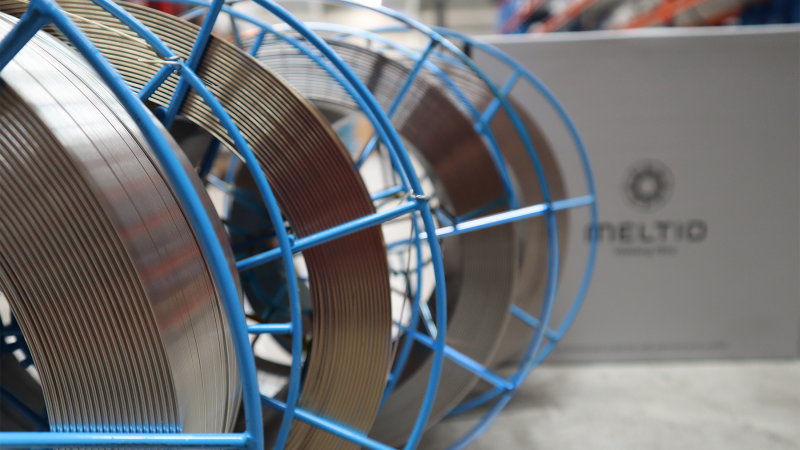

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or Wire drums

Stainless Steels:

Excellent strength and corrosion resistance.

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels:

High impact strength, retain hardness at high temperatures.

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance.

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Copper & Aluminum:

Under Development. Let me know when they are available.

Hot Wire:

Programmable power supply that preheats the material to increase the deposition rate.

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

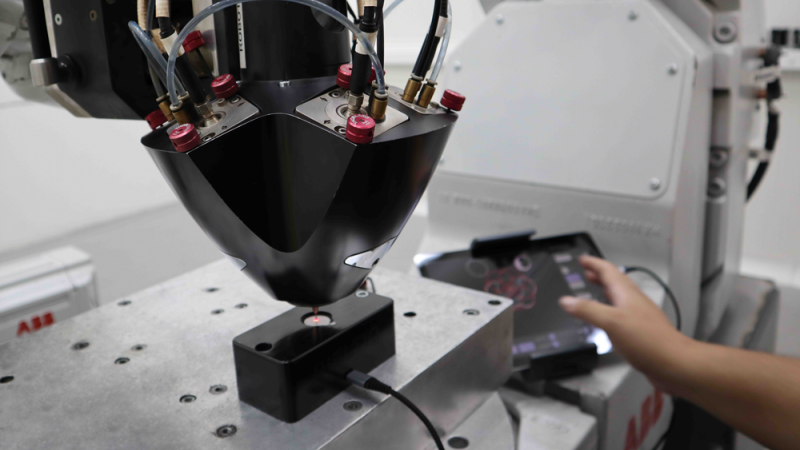

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

General Specifications

Dimensions (WxDxH):

560 × 600 × 1400 mm

Print Envelope (WxDxH):

145 x 168 x 390 mm

System Weight:

250 kg

Laser Type:

6 x 200 W direct diode lasers

Laser Wavelength:

976 nm

Power Input:

208 / 230 V single phase or 400 V three phase

Power Consumption:

2 – 5 kW peak depending on selected options

Process Control:

Closed-loop, laser and wire modulation

Enclosure:

Laser-safe, sealed, controlled atmosphere

Interface:

USB, ethernet, wireless datalink

Cooling:

Active water-cooled chiller included

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or Wire drums

Wire Materials

Stainless Steels:

Excellent strength and corrosion resistance.

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels:

High impact strength, retain hardness at high temperatures.

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance.

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Copper & Aluminum:

Under Development. Let me know when they are available.

Upgrades and Accessories

Hot Wire:

Programmable power supply that preheats the material to increase the deposition rate.

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

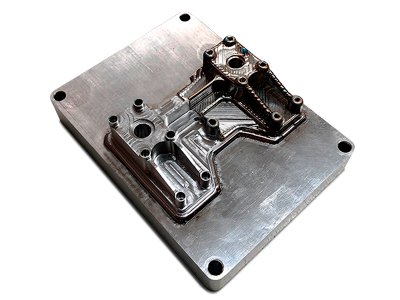

Meltio M450 Applications

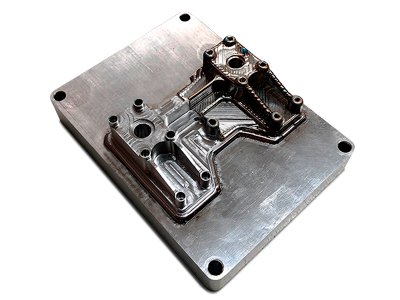

Aircraft Bracket

Titanium 64

Size:

109.6 x 160.8 x 34.8 mm

Weight:

2 kg

Print time:

13h 33′

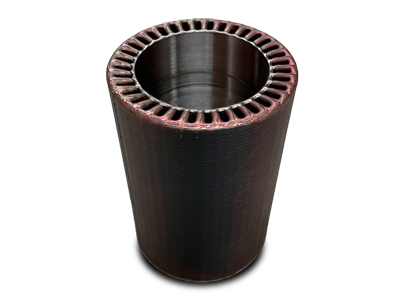

Dual Material Pipe

SS316L + Ni718

Size:

108 x 108 x 150 mm

Weight:

5 kg

Print time:

16h 37′

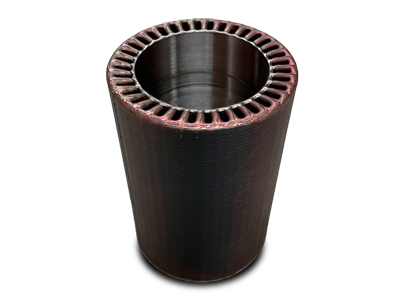

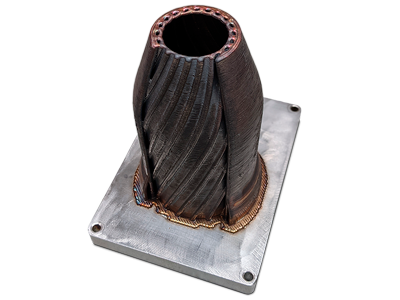

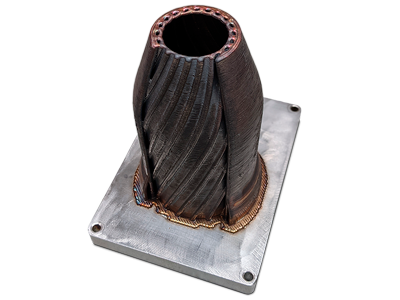

Combustion Chamber

SS316L

Size:

117 x 117 x 180 mm

Weight:

3 kg

Print time:

12h 17′

Aircraft Bracket

Titanium 64

Size:

109.6 x 160.8 x 34.8 mm

Weight:

2 kg

Print time:

13h 33′

Dual Material Pipe

SS316L + Ni718

Size:

108 x 108 x 150 mm

Weight:

5 kg

Print time:

16h 37′

Combustion Chamber

SS316L

Size:

117 x 117 x 180 mm

Weight:

3 kg

Print time:

12h 17′

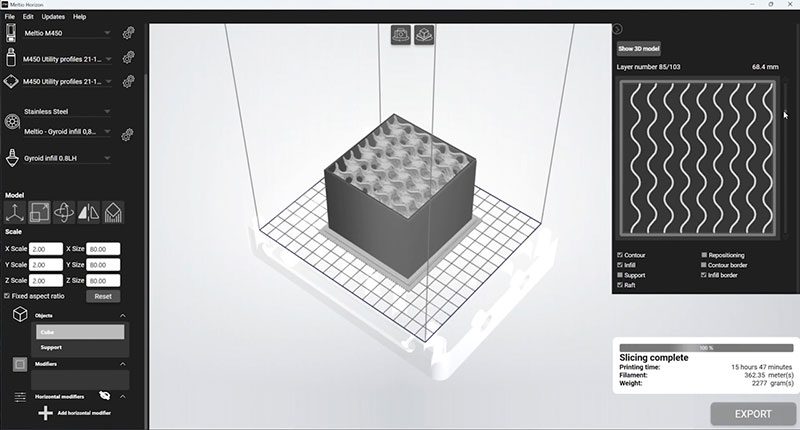

Meltio Horizon Software

Meltio Horizon is a proprietary slicer that ensures a fully tailored customer experience around our plug-and-play metal 3D printer, the Meltio M450, with its own unique features and custom-developed Meltio print and material profiles included.

Meltio Horizon Software

Meltio Horizon is a proprietary slicer that ensures a fully tailored customer experience around our plug-and-play metal 3D printer, the Meltio M450, with its own unique features and custom-developed Meltio print and material profiles included.

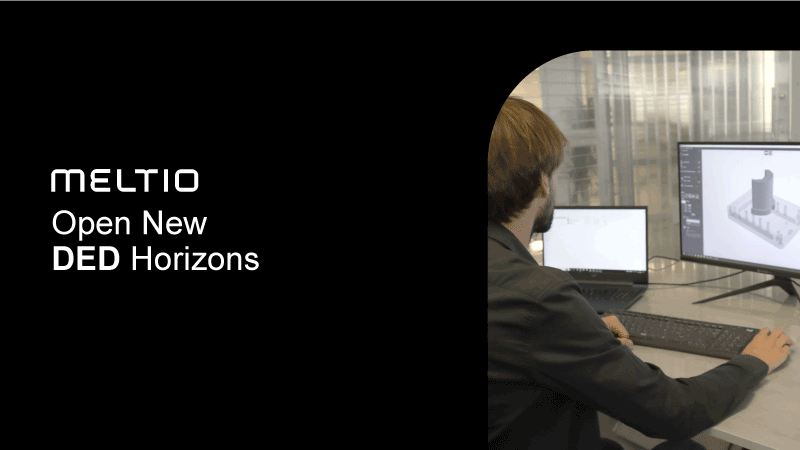

Meltio Horizon

Open New DED Horizons

It’s a proprietary toolpath generator software for 3-axis metal 3D printing, tailored specifically to our wire-laser deposition process with the Meltio M450 metal 3D printer.

Meltio Horizon

Open New DED Horizons

It’s a proprietary toolpath generator software for 3-axis metal 3D printing, tailored specifically to our wire-laser deposition process with the Meltio M450 metal 3D printer.

Laser Alignment System

The Laser Alignment System is a product developed by Meltio to aid the adoption of our state-of-the-art wire-laser deposition technology as well as to ensure print process reliability and enhance user experience.

Laser Alignment System

The Laser Alignment System is a product developed by Meltio to aid the adoption of our state-of-the-art wire-laser deposition technology as well as to ensure print process reliability and enhance user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single wire and dual wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single wire and dual wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Metal 3D Printing Experiences

Daniel Hasic

3D Printing Specialist / ROEZ

” I don’t know how much Meltio saved us, but I can tell you it saved us a lot, and then that’s why we bought the Meltio, to print this case and to reduce the cost of the machining and also reduce the cost of the raw material.

We chose the Meltio M450 as our first choice because we can print a lot of materials directly from the package. “

ROEZ is a Slovakian supplier of operating sets and investment units using a Meltio M450.

Get a Quote

Meltio M450

Receive a tailor-made offer within 1 – 2 business days.