Meltio Engine

Robot Integration

Large-Scale Metal

3D Printing

Turn a robot arm into a metal 3D printing system with no inherent size constraints. The Meltio Engine Robot Integration is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

The Meltio Engine integrates with any robot arm manufacturer and interface on the market.

Revolutionize the metal additive manufacturing of complex parts

The Meltio Engine integrates with any robot arm manufacturer and interface in the market.

Large-Scale

No inherent constraints when the working envelope is only limited by the size of the motion system.

Geometry Freedom

Create highly complex parts with infinite degrees of freedom.

Cladding

Provide new capability to any robot arm by turning it into a metal 3D printing system.

Part Repair

Create highly complex parts with machining tolerances in the same process.

Technical Specifications

Dimensions (WxDxH):

390 x 700-1300 x 1100-1025 mm

Print Envelope (WxDxH):

Depending on the integration

Control Unit Weight:

125 kg

Laser Type:

6 x 200 W direct diode lasers. Class IV

Laser Wavelength:

976 nm

Total Laser Power:

1200W

Power Input:

208/230V Three phase and 400V three phase are compatible

Power Consumption:

2 – 5 kW peak depending on selected options

Printhead Weight:

15.5 kg

Printhead Size (WxDxH):

230 x 310 x 710 mm

Process Control:

Closed-loop, laser and wire modulation

Enclosure:

Laser-safe, sealed, controlled atmosphere

Cooling:

Active water-cooled chiller included

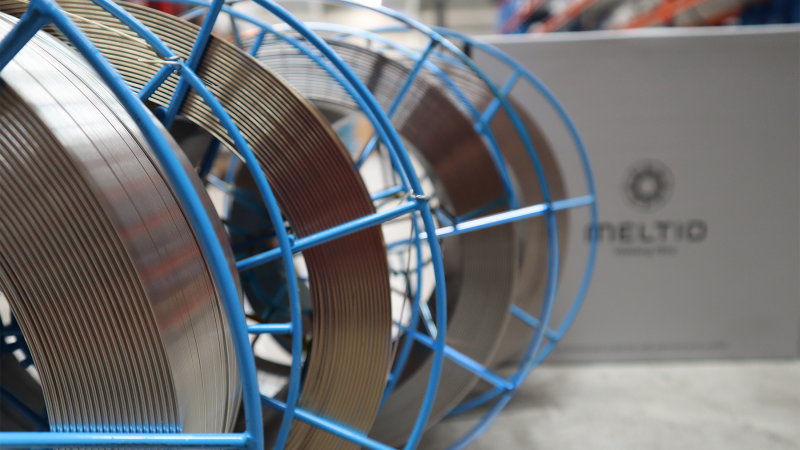

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or Wire drums

Stainless Steels:

Excellent strength and corrosion resistance.

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels:

High impact strength, retain hardness at high temperatures.

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance.

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Copper & Aluminum:

Under Development. Let me know when they are available.

Payload of at least 45 – 60 kg ensures that the robot can follow the additive toolpath precisely.

Position repeatability of ± 0.06 mm according to ISO 9283.

At least 8 Digital I/O configured according to “Communications Protocols Robot Meltio Engine”.

When using OPC DA or Socket as the default communication protocol, Meltio recommends a total of 16 Digital I/O.

The robot and the ositioner must be installed, configured, and calibrated before the Meltio Engine Integration.

Possibility to add safety integration (depending on the integration).

Laser-safe robot cell with a security circuit between the robot controller, the Meltio Engine, and the cell door interlock.

The integrator is responsible for the correct installation and operation of the security system.

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Hot Wire:

Programmable power supply that preheats the material to increase the deposition rate.

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

General Specifications

Dimensions (WxDxH):

390 x 700-1300 x 1100-1025 mm

Print Envelope (WxDxH):

Depending on the integration

Control Unit Weight:

125 kg

Laser Type:

6 x 200 W direct diode lasers. Class IV

Laser Wavelength:

976 nm

Total Laser Power:

1200W

Power Input:

208 / 230 V single phase or 400 V three phase

Power Consumption:

2 – 5 kW peak depending on selected options

Printhead Weight:

15.5 kg

Printhead Size (WxDxH):

230 x 310 x 710 mm

Process Control:

Closed-loop, laser and wire modulation

Enclosure:

Laser-safe, sealed, controlled atmosphere

Cooling:

Active water-cooled chiller included

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or Wire drums

Wire Materials

Stainless Steels:

Excellent strength and corrosion resistance.

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels:

High impact strength, retain hardness at high temperatures.

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance.

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Cooper & Aluminum:

Under Development. Let me know when they are available.

Key Integration Requirements

Payload of at least 45 – 60 kg ensures that the robot can follow the additive toolpath precisely.

Position repeatability of ± 0.06 mm according to ISO 9283.

At least 8 Digital I/O configured according to “Communications Protocols Robot Meltio Engine”.

When using OPC DA or Socket as the default communication protocol, Meltio recommends a total of 16 Digital I/O.

The robot and the ositioner must be installed, configured, and calibrated before the Meltio Engine Integration.

Possibility to add safety integration (depending on the integration).

Laser-safe robot cell with a security circuit between the robot controller, the Meltio Engine, and the cell door interlock.

The integrator is responsible for the correct installation and operation of the security system.

Upgrades and Accessories

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Hot Wire:

Programmable power supply that preheats the material to increase the deposition rate.

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

Meltio Robot Applications

Rotary Screw Compressor

SS316L

Size:

75 x 75 x 230 mm cladded

Weight:

3 kg

Print time:

21h 16′

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

Print time:

21h 23′

Spherical Tank

SS316L

Size:

500 Ø mm

Weight:

30 kg

Print time:

6h 26′

Rotary Screw Compressor

SS316L

Size:

75x 75 x 230 mm cladded

Weight:

3 kg

Print time:

21h 16′

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

Print time:

21h 23′

Spherical tank

SS316L

Size:

500 Ø mm

Weight:

30 kg

Print time:

6h 26′

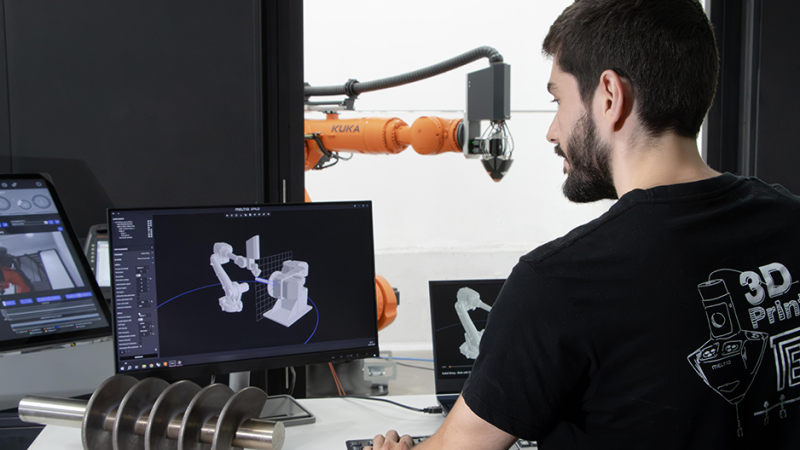

Meltio Space Software

This toolpath generator software is specifically developed for accelerated adoption of Meltio technology, revolutionizes the field of robotic additive manufacturing. With its intuitive design, users can quickly adapt to and leverage the benefits of robotic additive manufacturing without requiring expertise in robotics or programming.

Meltio Space Software

This toolpath generator software is specifically developed for accelerated adoption of Meltio technology, revolutionizes the field of robotic additive manufacturing. With its intuitive design, users can quickly adapt to and leverage the benefits of robotic additive manufacturing without requiring expertise in robotics or programming.

Wire-Laser

DED Applications

Discover Meltio’s Wire-Laser DED applications with our state-of-the-art welding wire-based technology.

Wire-Laser

DED Applications

Discover Meltio’s Wire-Laser DED applications with our state-of-the-art welding wire-based technology.

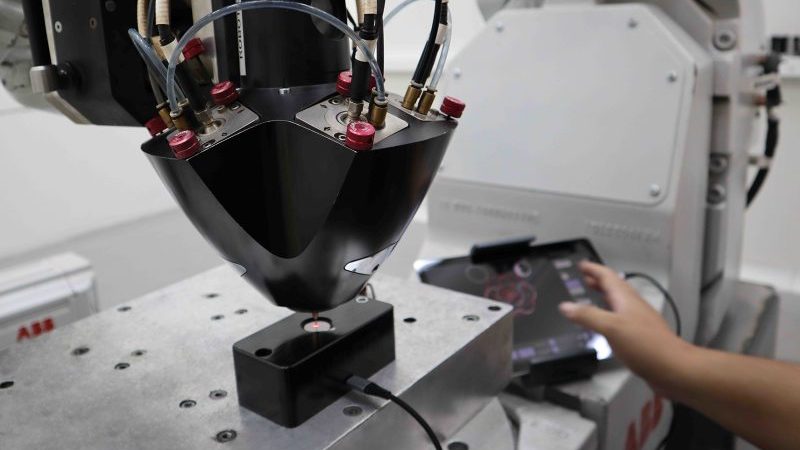

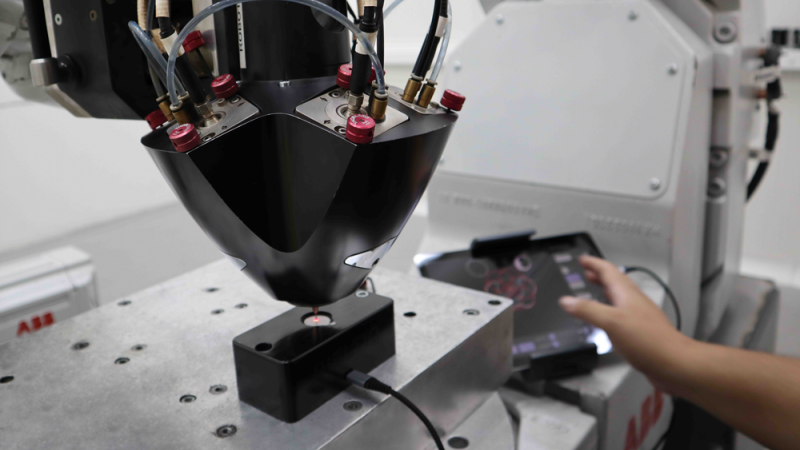

Laser Alignment System

The Laser Alignment System is a product developed by Meltio to aid the adoption of our state-of-the-art wire-laser deposition technology as well as to ensure print process reliability and enhance user experience.

Laser Alignment System

The Laser Alignment System is a product developed by Meltio to aid the adoption of our state-of-the-art Wire-laser deposition technology as well as to ensure print process reliability and enhance user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Metal 3D Printing Experiences

Miguel Peñaranda

Additive Manufacturing Engineer / K3D

” We chose the Meltio product because we found the best balance between high deposition rates and good quality for the task at hand.

Meltio represents for us the right balance between a high deposition speed as well as a high printing size with the best feasible quality or resolution. “

K3D is a Dutch Service Bureau that prints different parts for end-users across various industries using a Meltio M450 and a Meltio Engine Robot Integration.

Get a Quote

Meltio Engine Robot Integration

Receive a tailor-made offer within 1 – 2 business days.