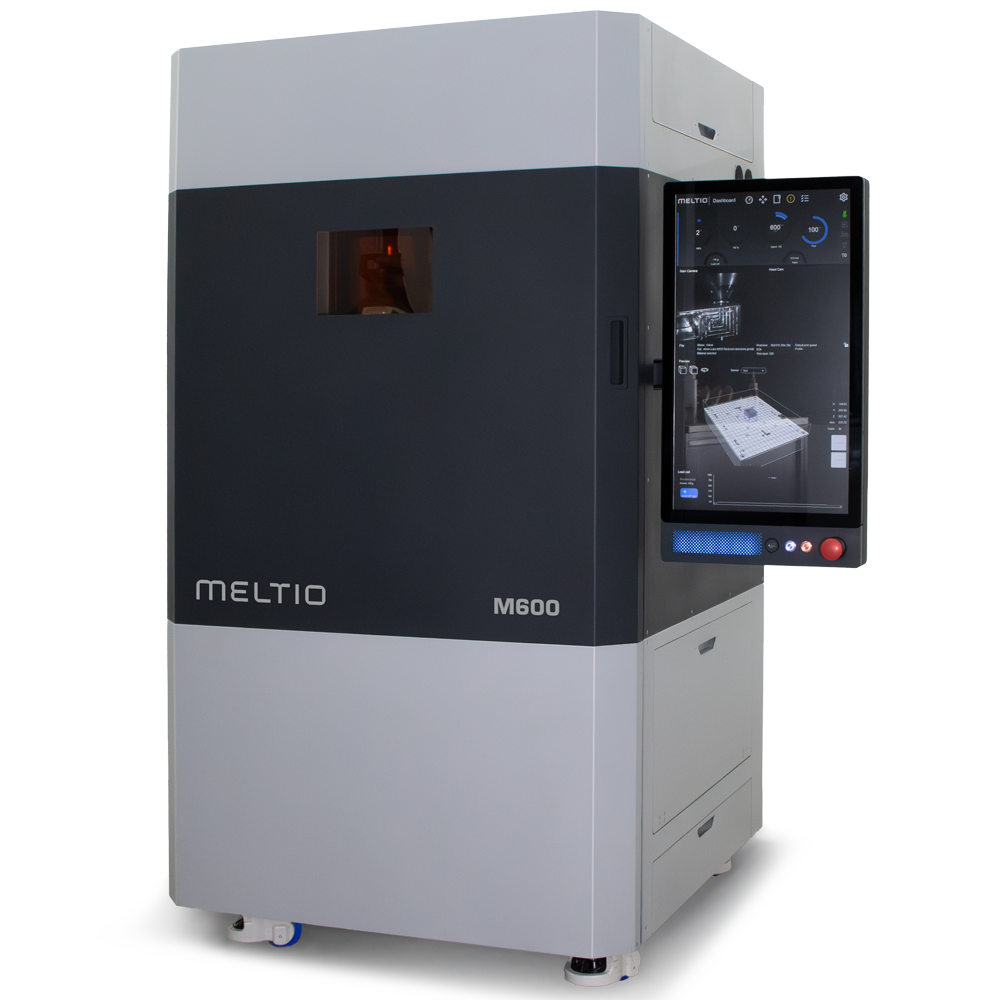

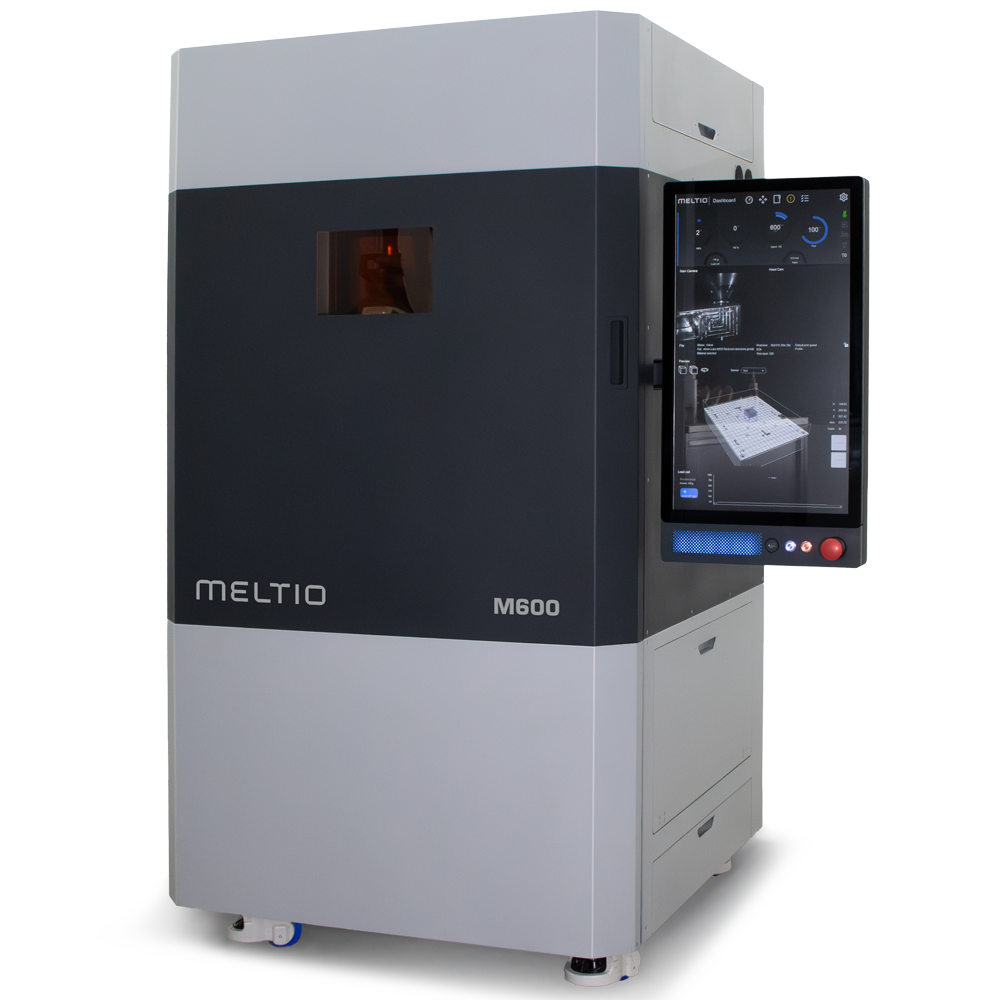

Meltio M600

Industrial Metal

3D Printer

Expand your manufacturing capabilities with blue lasers, a large build volume, and a fully inert chamber for the best material properties. Printing is easier than ever thanks to the improved process control, advanced sensors and live monitoring allowing you to produce parts consistently 24/7.

The Meltio M600, with its built-in 3-axis probing system and work-holding solutions, is the ideal companion for your manufacturing operations.

The All-in-one Printing Platform

The Meltio M600 allows to printing of large parts or a batch of small parts in a row, simultaneously. Improved process control for stability and repeatibility.

Production Ready

Bigger parts, higher deposition rate, larger material range, inert print chamber, less maintenance, and built-in work holding solutions.

Reliable

Boosted wire feeding system, fiber-free deposition head, improved process control systems, and much more.

Easy-to-use

Minimized operator interaction thanks to advanced sensor solutions, simplified UI, dedicated slicer, and zero point clamping system.

Reduced Maintenance

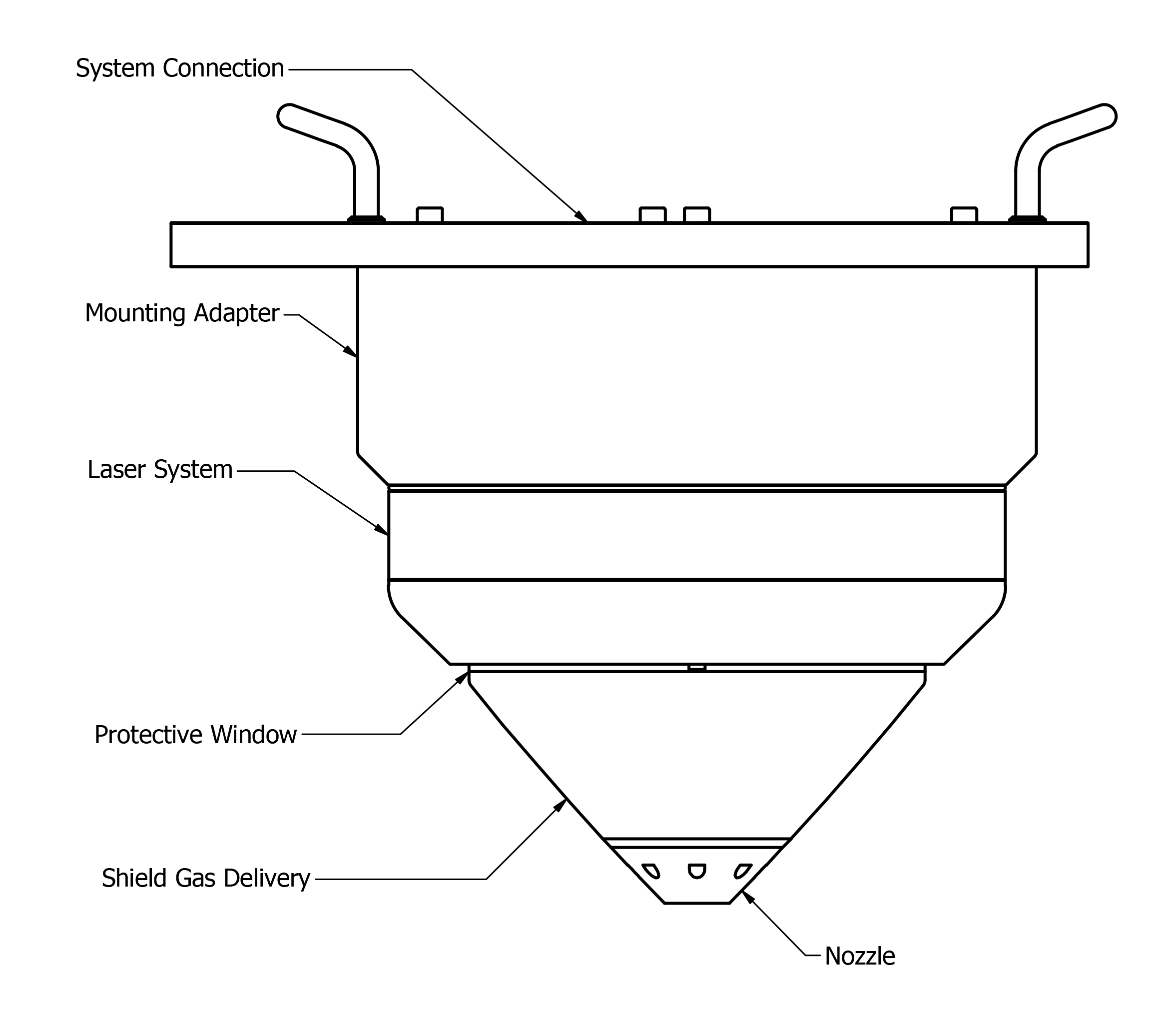

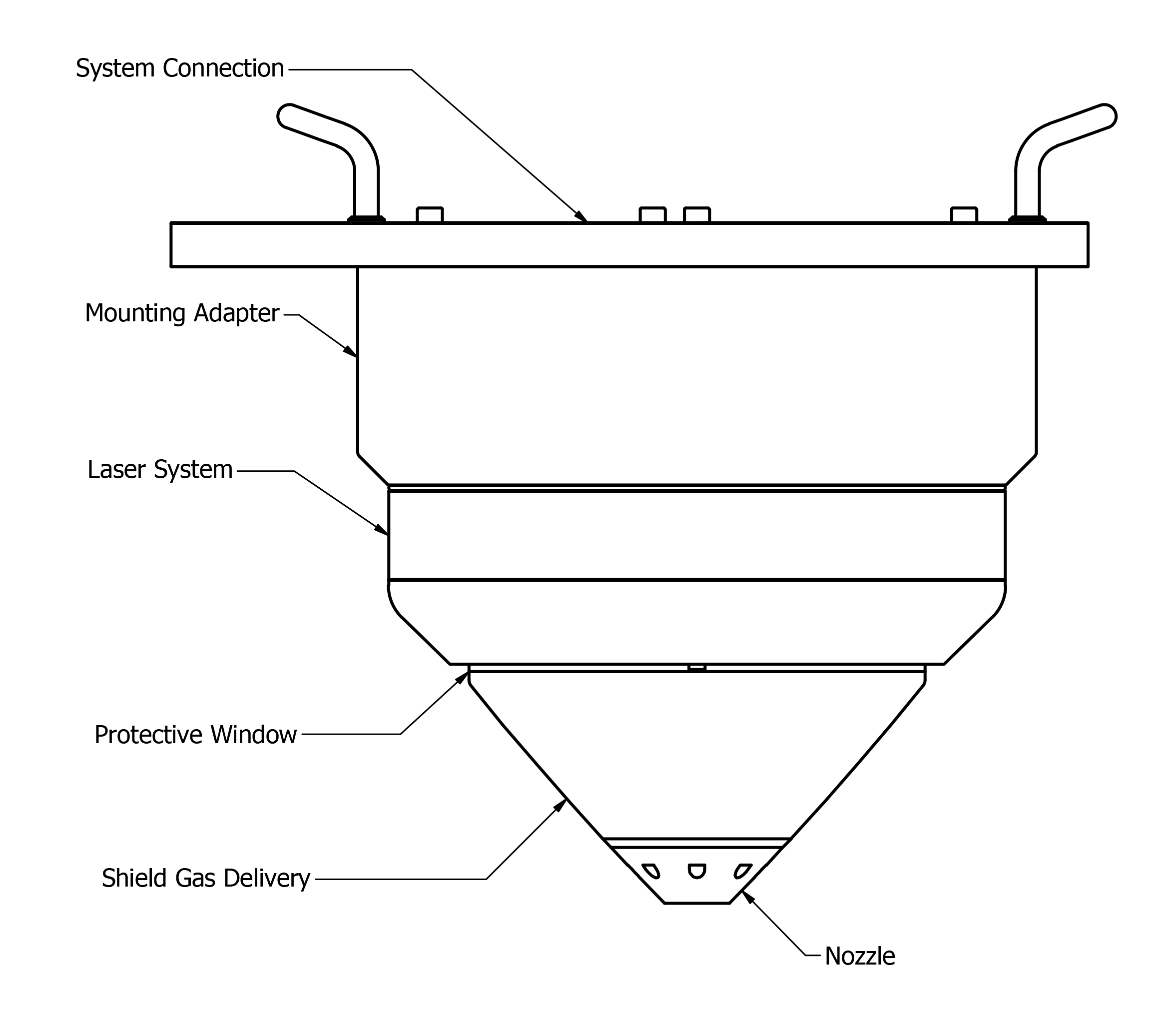

The newly developed deposition head removes the need for laser alignment, while the motion system has been improved to ensure maximum lifetime.

Blue is the new green

Augmented energy delivery efficiency reduces electricity consumption, making it a cost-saving process, thanks to the blue laser diodes.

Blue Light

450 nm light improves energy absorption and printing efficiency across the metal material spectrum.

Hotwire Compatible

The deposition head is developed to used with an optional hotwire supply to increase the deposition rate and allow for more materials to be processed.

No Calibration

It arrives aligned from the factory for maximum printing repeatability and minimal maintenance.

High Efficiency

The energy consumption per component is reduced significantly, resulting in a greener and more cost-efficient process.

Blue is the new green

Augmented energy delivery efficiency reduces electricity consumption, making it a cost-saving process, thanks to the blue laser diodes.

Technical Specifications

Dimensions (WxDxH):

1050 x 1050 x 1950 mm

Print Envelope (WxDxH):

300 x 400 x 600

System Weight:

800 – 1000 kg (depending on options)

Movement System:

Servo Motor Linear axis with Absolute encoder on all axis

Filtration System:

3 Stage Particulate and Chemical Filtration included

Environment Control:

Control O2 and Humidity level

Laser Type:

9x Direct Diode Lasers

Laser Wavelength:

450 nm (Blue)

Total Laser Power:

1000 W

Power Input:

208/230V Three phase and 400V three phase are compatible

Power Consumption:

4 – 6 kW Peak depending on selected options

Process Control:

Closed-loop, Laser and Wire Modulation

Touch Probe:

Automated XYZ Touch Probe integrated

Enclosure:

Laser-safe, Controlled inert atmosphere

Interface:

USB, Ethernet, WiFi

Cooling:

Active Water cooled chiller included

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or External Wire Drum

Stainless Steels:

Excellent strength and corrosion resistance

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability

Carbon Steels:

High impact strength, retain hardness at high temperatures

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Copper & Aluminum:

Conductivity and corrosion resistance & lightweight strength.

Parameters under development. Let me know when they are available

Hot Wire:

Programmable power supply that preheats the material to increase the deposition rate.

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Quad Wire:

This option allows for sequential 3D Printing of up to four materials with very fast automatic wire switches.

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

General Specifications

Dimensions (WxDxH):

1050 x 1050 x 1950 mm

Print Envelope (WxDxH):

300 x 400 x 600

System Weight:

800 – 1000 kg (depending on options)

Movement System:

Servo Motor Linear axis with Absolute encoder on all axis

Filtration System:

3 Stage Particulate and Chemical Filtration included

Environment Control:

Control O2 and Humidity level

Laser Type:

9x Direct Diode Lasers

Laser Wavelength:

450 nm (Blue)

Total Laser Power:

1000 W

Power Input:

400 V Three Phase

Power Consumption:

4 – 6 kW Peak depending on selected options

Process Control:

Closed-loop, Laser and Wire Modulation

Touch Probe:

Automated XYZ Touch Probe integrated

Enclosure:

Laser-safe, Controlled inert atmosphere

Interface:

USB, Ethernet, WiFi

Cooling:

Active Water cooled chiller included

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or External Wire Drum

Wire Materials

Stainless Steels:

Excellent strength and corrosion resistance

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability

Carbon Steels:

High impact strength, retain hardness at high temperatures

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Copper & Aluminum:

Conductivity and corrosion resistance & lightweight strength.

Parameters under development. Let me know when they are available

Upgrades and Accessories

Hot Wire:

Programmable power supply that preheats the material to increase the deposition rate.

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Quad Wire:

This option allows for sequential 3D Printing of up to four materials with very fast automatic wire switches.

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

Meltio M600 Applications

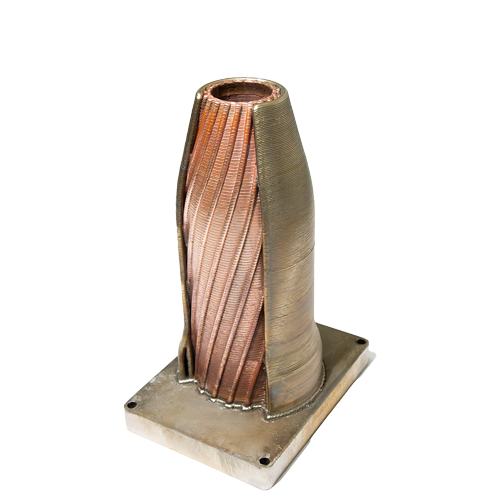

DM Combustion Chamber

Inconel 718 + Copper

Size:

131 x 200 x 176 mm

Weight:

6.4 kg

Print time:

47h 23′

Bracket

SS316L

Size:

153 x 345 x 275 mm

Weight:

18.6 kg

Print time:

48h

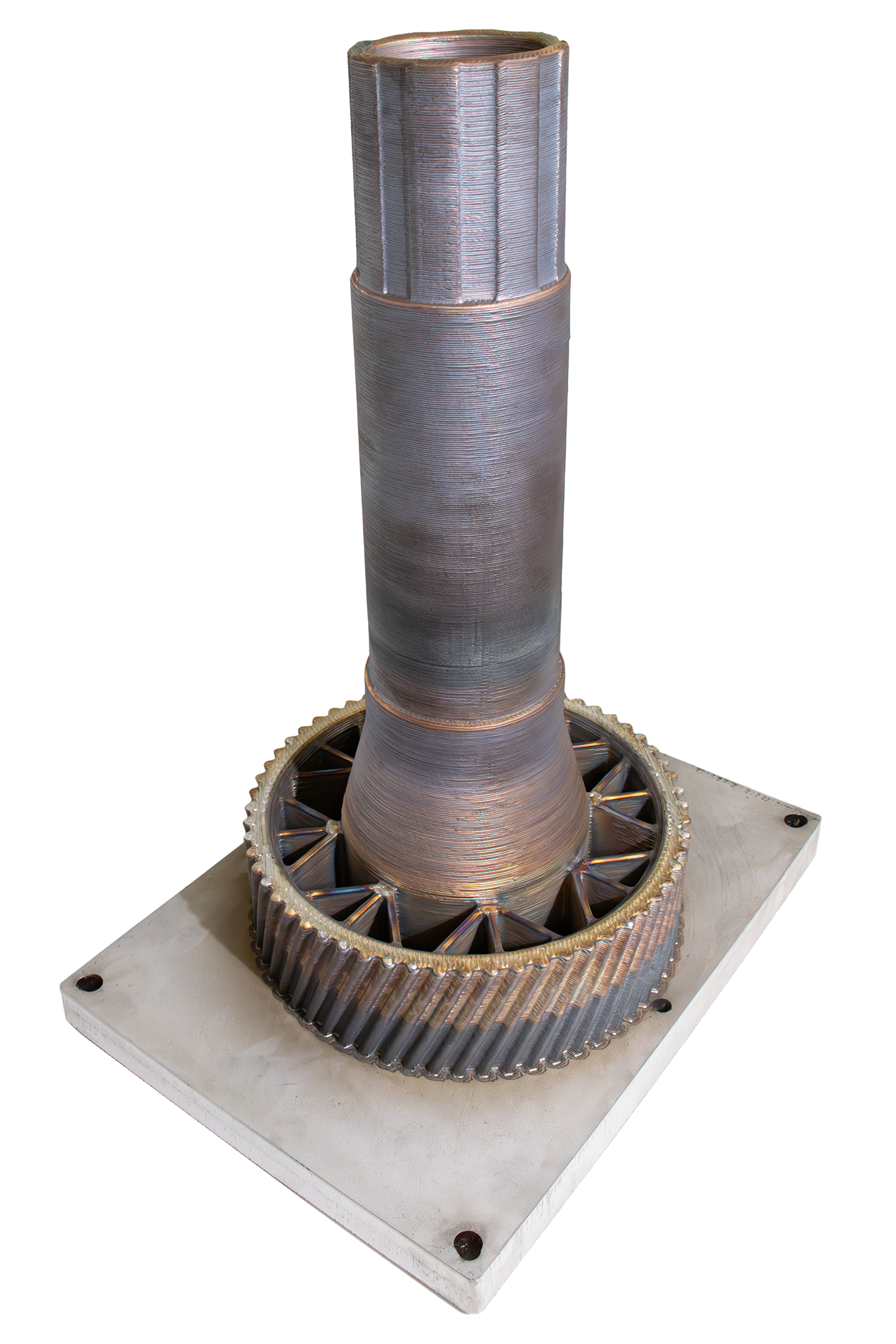

Gear

SS316L

Size:

260 mm Ø x 500 mm

Weight:

25 kg

Print time:

15h

Gear

SS316L

Size:

260 mm Ø x 500 mm

Weight:

25 kg

Print time:

47h 23′

Bracket

SS316L

Size:

153 x 345 x 275 mm

Weight:

18.6 kg

Print time:

48h

DM Combustion Chamber

Inconel 718 + Copper

Size:

131 x 200 x 176 mm

Weight:

6.4 kg

Print time:

15h

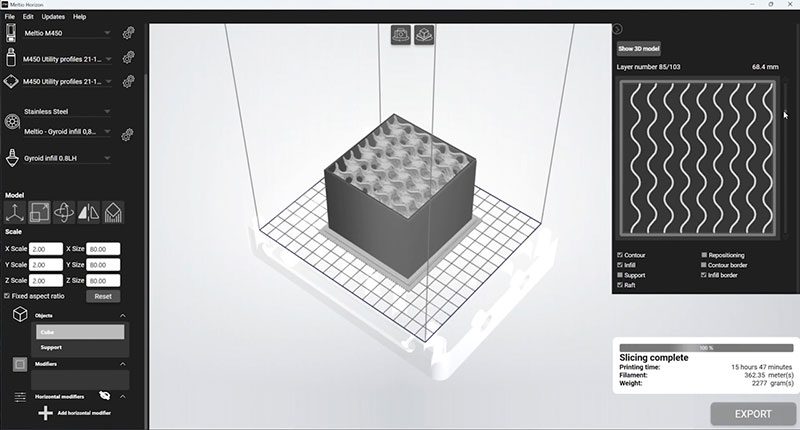

Meltio Horizon Software

Meltio Horizon is a proprietary slicer that ensures a fully tailored customer experience around our industrial metal 3D printer, the Meltio M600, with its own unique features and custom-developed Meltio print and material profiles included.

Meltio Horizon Software

Meltio Horizon is a proprietary slicer that ensures a fully tailored customer experience around our industrial metal 3D printer, the Meltio M600, with its own unique features and custom-developed Meltio print and material profiles included.

Meltio M600

Plug, Press Play & Print

Discover all the features of our new brand industrial metal 3D printer, the Meltio M600, which allows you to produce parts at an industrial rate with the benefits of metal 3D printing

Meltio M600

Plug, Press Play & Print

Discover all the features of our new brand industrial metal 3D printer, the Meltio M600, which allows you to produce parts at an industrial rate with the benefits of metal 3D printing.

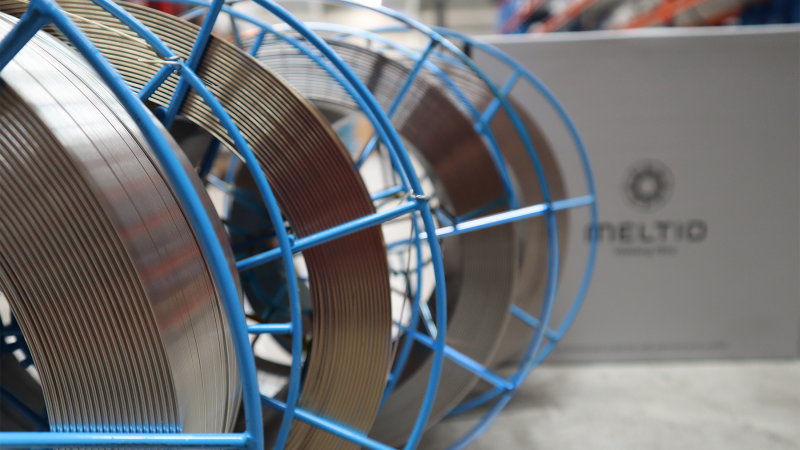

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual, and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Get a Quote

Meltio M600

Receive a tailor-made offer within 1 – 2 business days.