Metal 3D Printing Applications

A match for your industrial needs

From lab research to part replacement, Meltio enables applications across industrial prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance and repair.

Metal Applications with Disruptive Technology

From unique applications to the best efficiency in cost without losing top mechanical properties.

Dual Material

Print dual wire for hard-facing or anti-corrosion applications to create new alloys on the fly.

Cost-Efficient

Meltio’s multi-laser metal deposition process allows the wire to enter the molten pool coaxially, having 0 % material waste.

Mechanical Properties

Meltio LMD process can produce fully dense parts, achieving the best mechanical properties.

Near-Net Shape

Our technology produces high-resolution near-net shape parts. Thanks to this and part repairs, we can reduce material usage by up to 90 %.

Meltio M450 Applications

Aircraft Bracket

Titanium 64

Size:

109.6 x 160.8 x 34.8 mm

Weight:

2 kg

Dual Material Pipe

SS316L + Ni718

Size:

108 x 108 x 150 mm

Weight:

5 kg

Rocket Nozzle

SS316L

Size:

117 x 117 x 180 mm

Weight:

3 kg

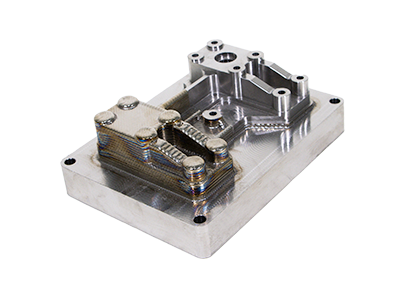

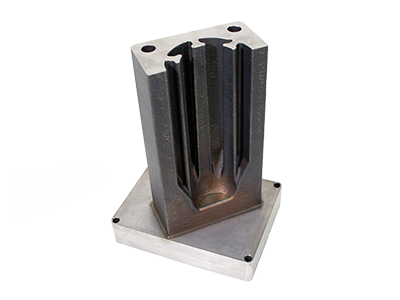

Injection Mold Half

SS316L

Size:

140 x 140 x 297 mm

Weight:

15 kg

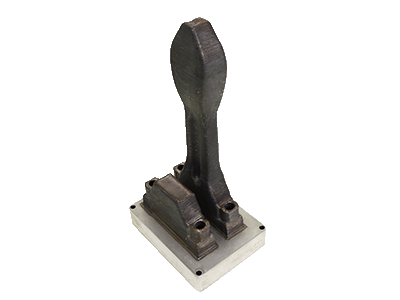

Connecting Rod

SS316L

Size:

49.6 x 156.4 x 332.8 mm

Weight:

10 kg

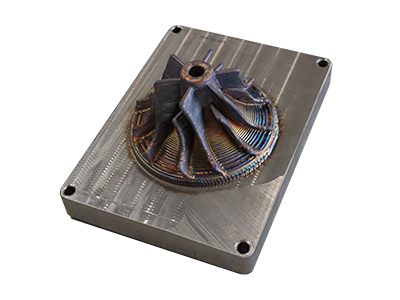

Turbo Impeller

SS316L

Size:

99 x 99 x 49.5 mm

Weight:

1 kg

Meltio M600 Applications

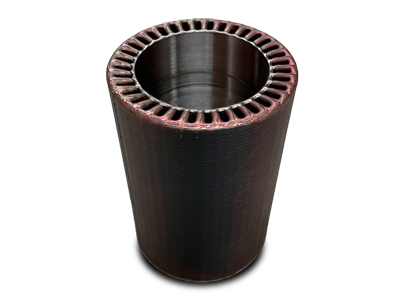

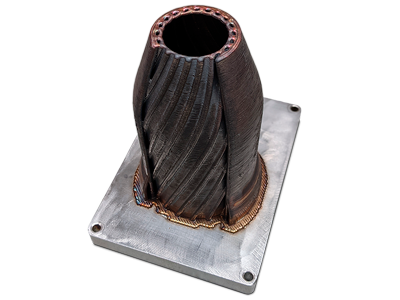

DM Combustion Chamber

Inconel 718 + Copper

Size:

131 x 200 x 176 mm

Weight:

6.4 kg

Bracket

SS316L

Size:

153 x 345 x 275 mm

Weight:

18.6 kg

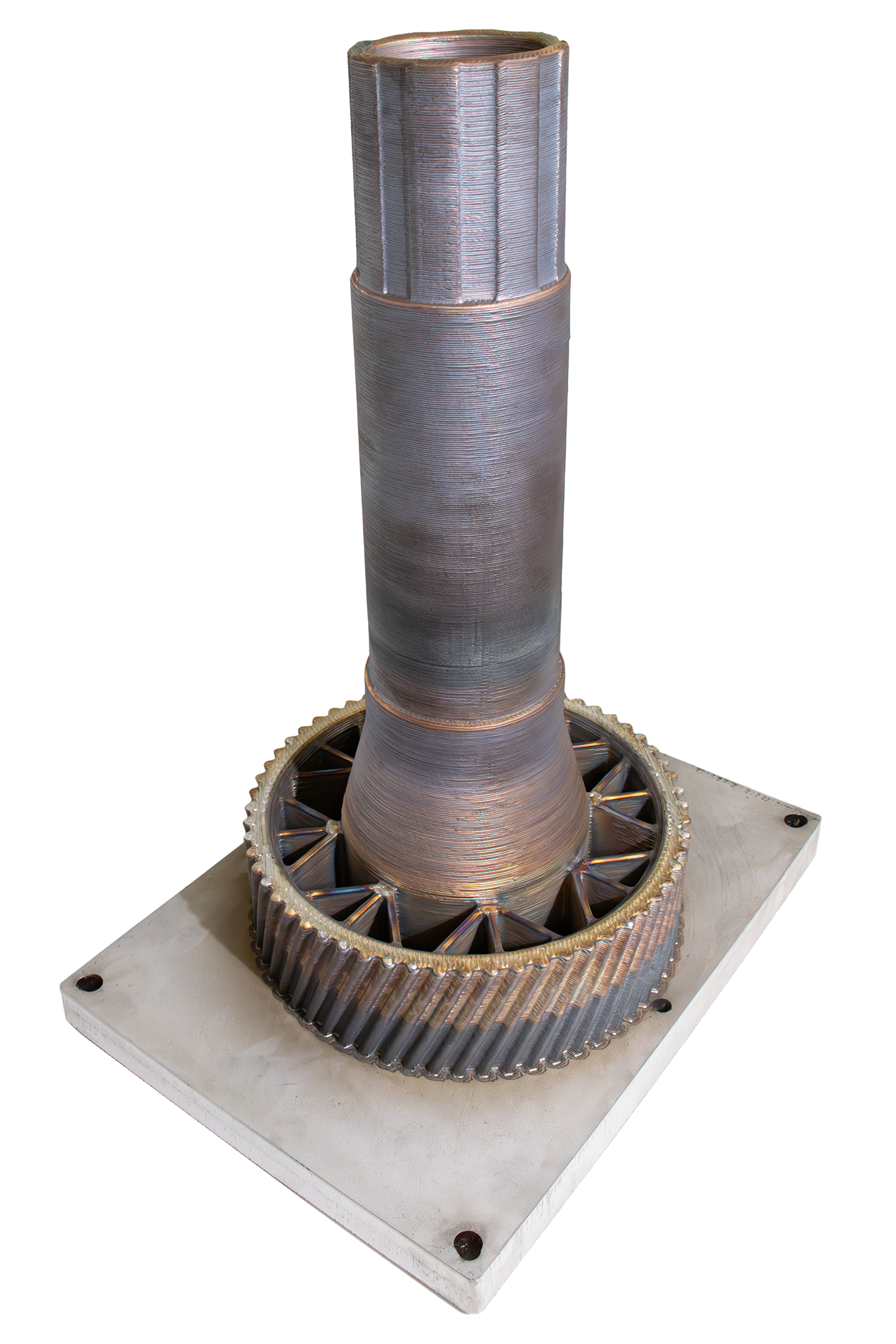

Gear

SS316L

Size:

260 mm Ø x 500 mm

Weight:

25 kg

Meltio Engine CNC Applications

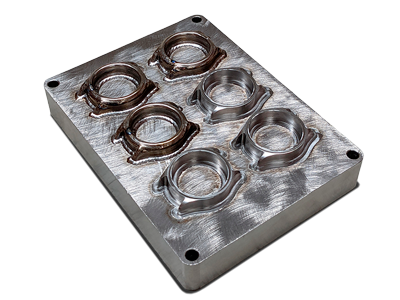

Watch Bezels

Titanium 64

Size:

50 x 45.9 x 12.7 mm

Weight:

0.25 kg

Elbow

SS316L

Size:

ext. 70 Ø – int. 50 Ø mm

Weight:

0.51 kg

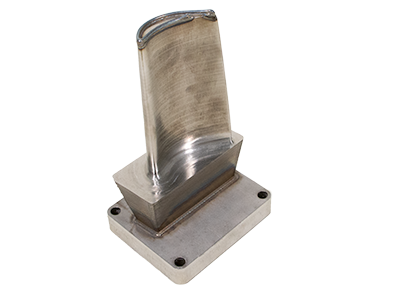

Gas Turbine Blade Repair

Nickel 625

Size:

65 x 29 x 6 mm

Weight:

0.015 kg

Meltio Engine Robot Applications

Rotary Screw Compressor

SS316L

Size:

75 x 75 x 230 mm cladded

Weight:

3 kg

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

Spherical Tank

SS316L

Size:

500 Ø mm

Weight:

30 kg

Blisk

SS316L

Size:

500 x 500 x 60 mm cladded

Weight:

10 kg

Conveyor Belt Support

SS316L

Size:

130 x 903 x 855 mm

Weight:

5 kg

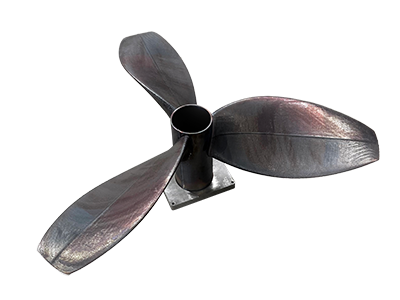

Naval Propeller 3 Blades

SS316L

Size:

900 x 900 x 250 mm

Weight:

11 kg

Download our Printable Materials list

Download our Printable Materials list

Download our Printable Materials list

Wire-Laser

DED Applications

Discover Meltio’s Wire-Laser DED applications with our state-of-the-art welding wire-based technology.

Wire-Laser

DED Applications

Discover Meltio’s Wire-Laser DED applications with our state-of-the-art welding wire-based technology.

Metal 3D Printing Solutions

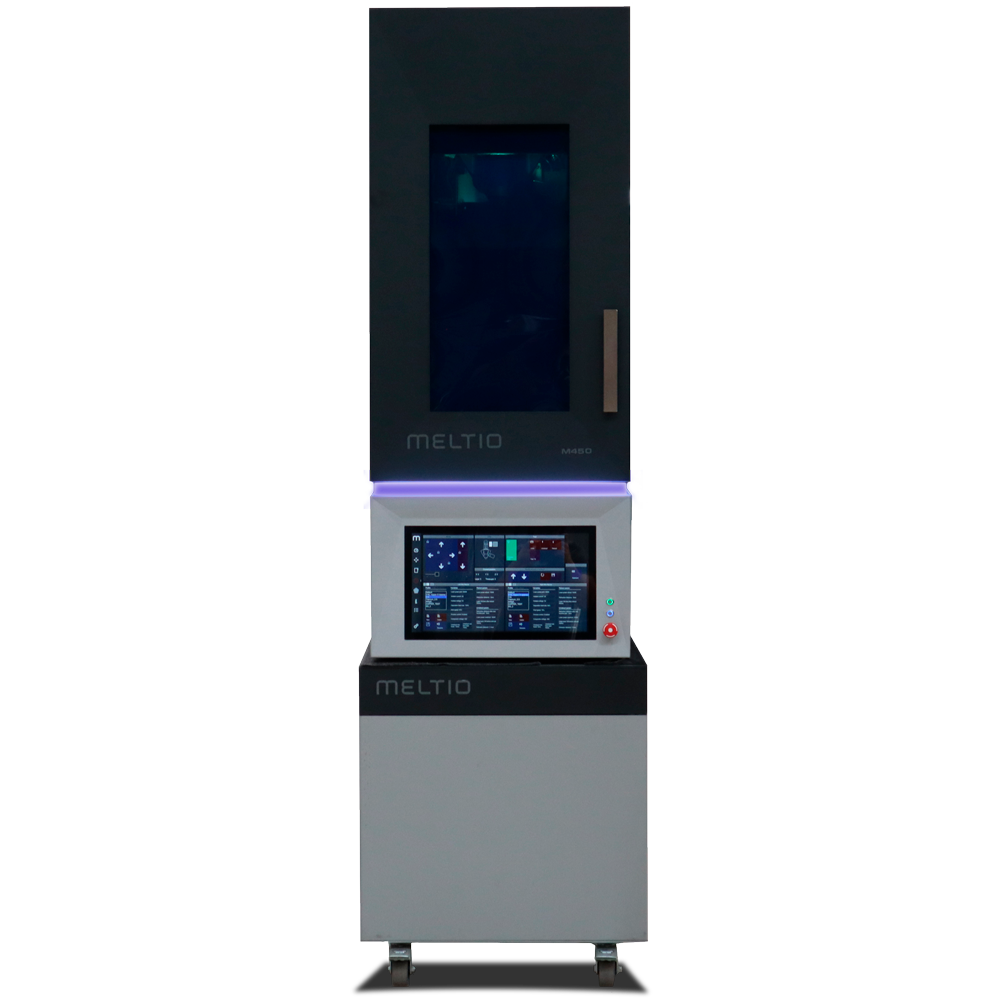

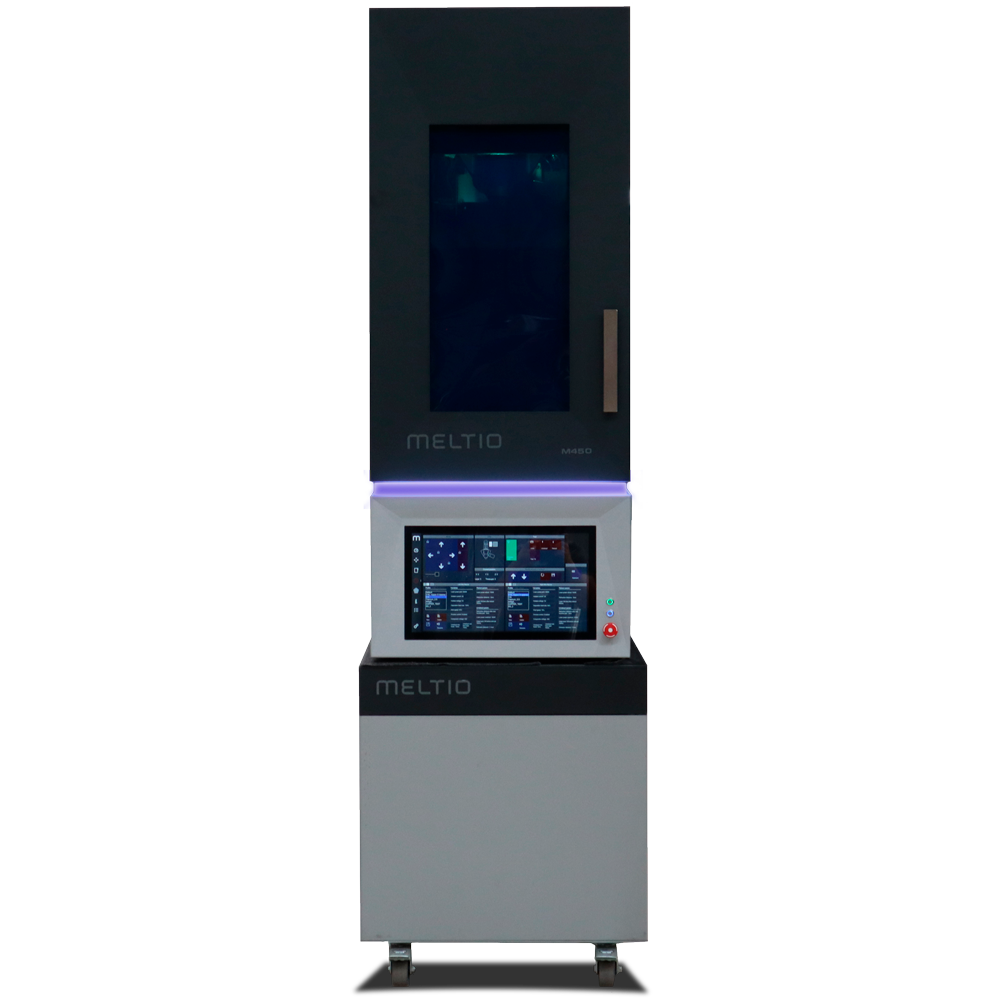

Meltio M450

Metal 3D Printer

Turn-key Metal 3D Printer.

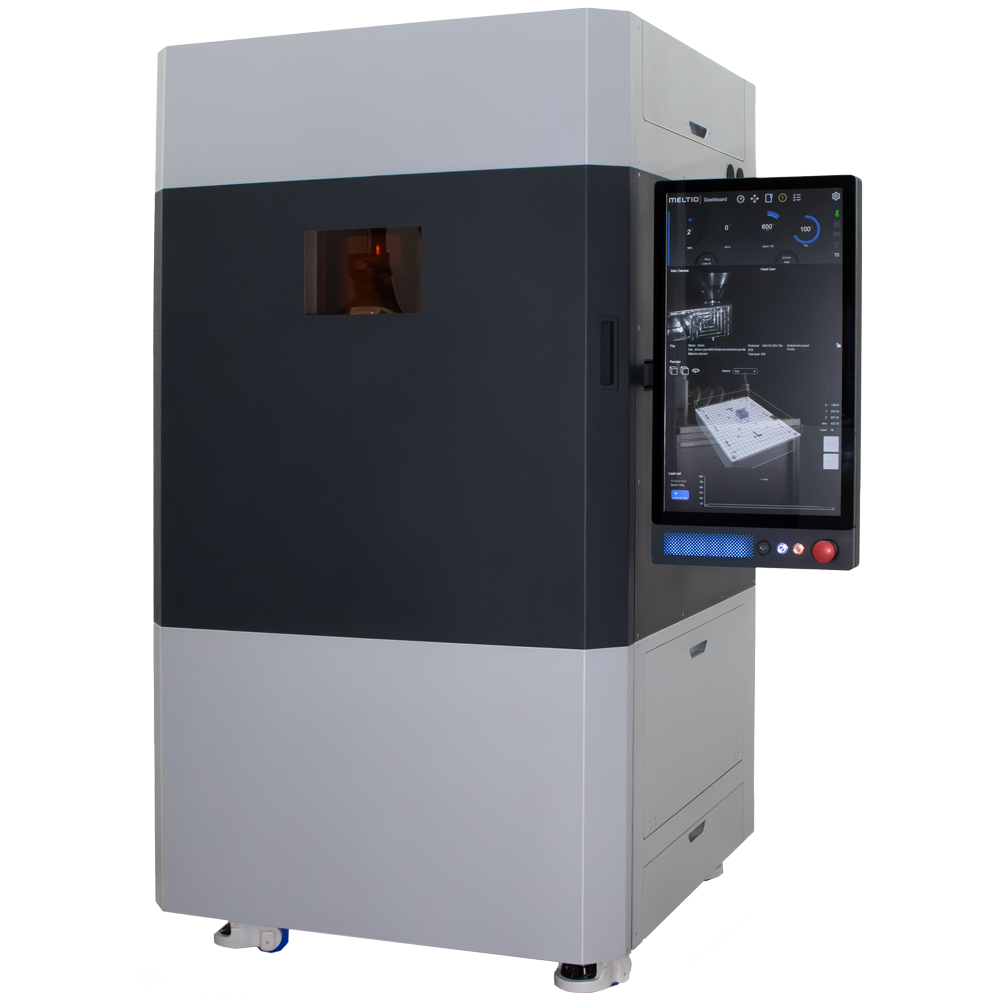

Meltio M600

Industrial Metal 3D Printer

Ideal companion for your industrial operations.

Meltio

Robot Cell

Meltio Engine

CNC Integration

Meltio Engine

Robot Integration

For large, complex parts, laser cladding, and repairing.

Meltio M450

Metal 3D Printer

Turn-key metal 3D printer.

Meltio M600

Industrial Metal 3D Printer

Ideal companion for your industrial operations.

Meltio

Robot Cell

Meltio Engine

Robot Integration

For large, complex parts, laser cladding, and repairing.

Meltio Engine

CNC Integration

Hybrid Manufacturing System.