by Meltio | Sep 19, 2023 | Knowledge Base

This blog post provides a comprehensive overview of repair strategies for metal additive manufacturing (AM) technology. It explores repair techniques available for Meltio’s technology AM and emphasizes the importance of selecting appropriate repair strategies based on...

by Meltio | Sep 18, 2023 | Knowledge Base

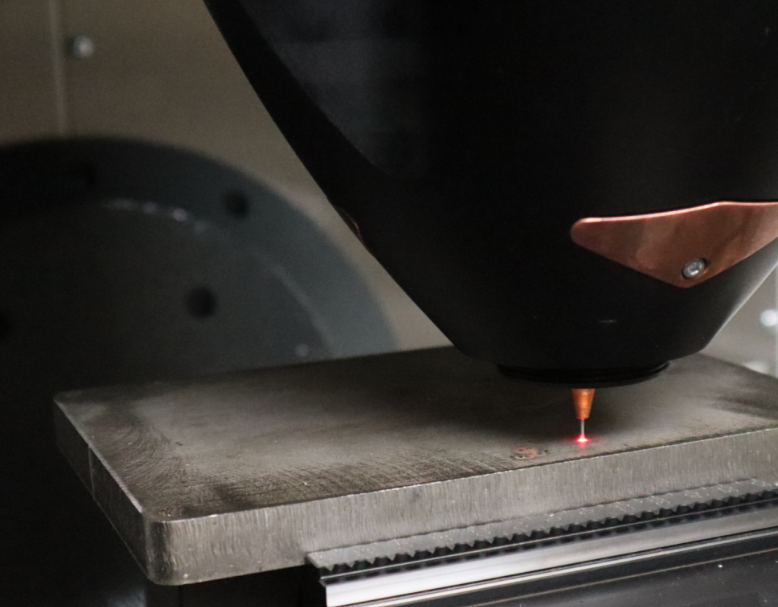

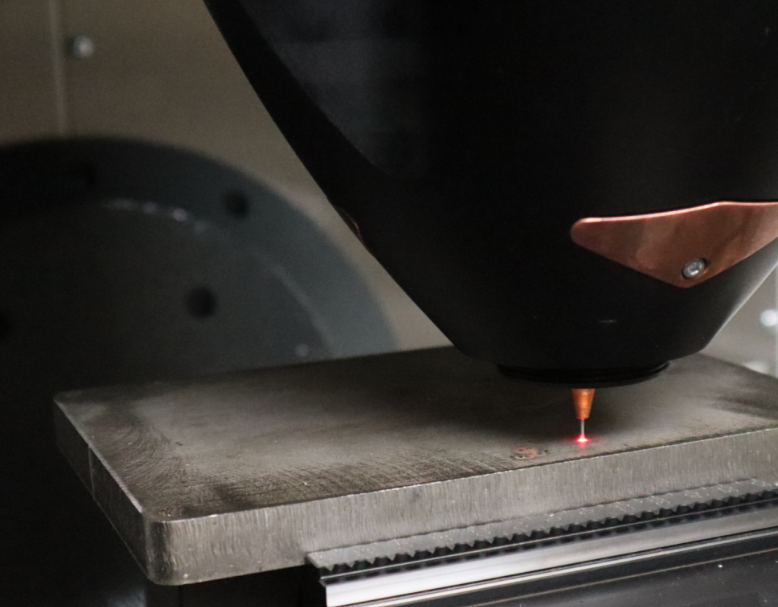

Within the domain of 3D metal printing, specifically in Wire-Laser Directed Energy Deposition (DED), the concept of process control plays a critical role in ensuring optimal printing results. The primary goal is to maintain a delicate energy balance between the...

by Meltio | Sep 18, 2023 | Knowledge Base

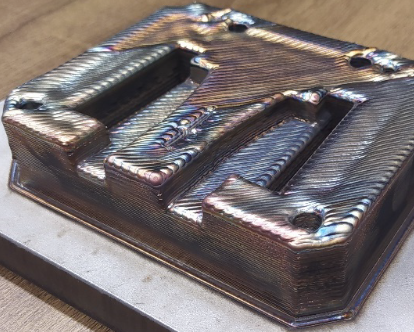

This blog post aims to provide an explanation of the concepts of near net shape and over thickness, which are highly relevant to Meltio’s Wire-LMD technology. Additionally, it will offer a concise overview of when, how, and how much over thickness should be...

by Meltio | Sep 6, 2023 | Knowledge Base

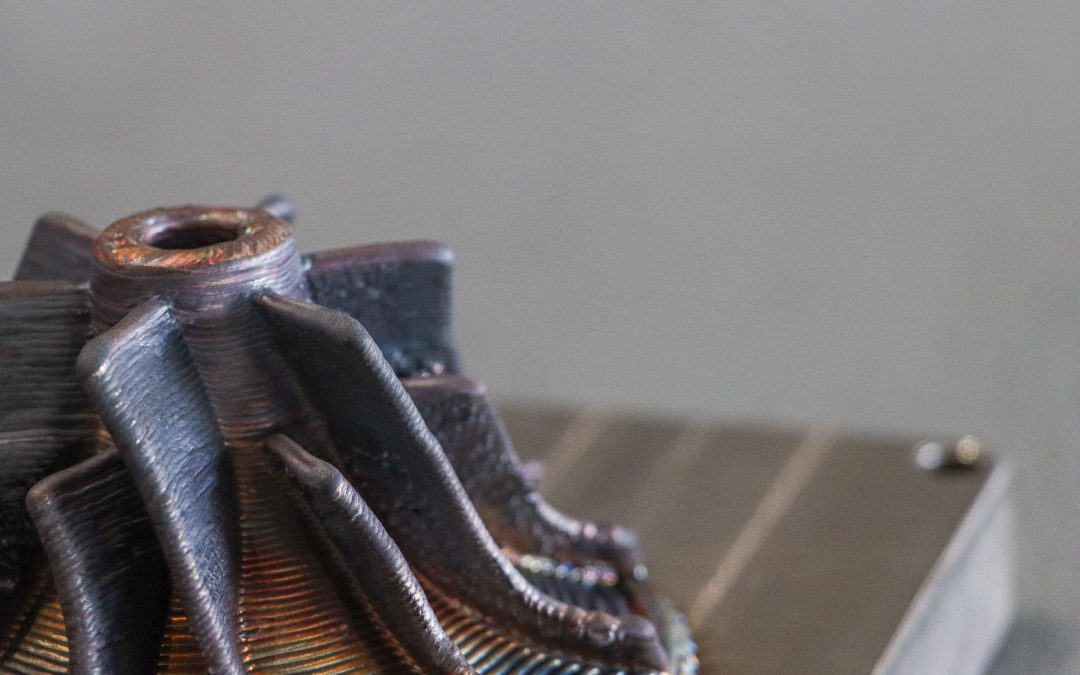

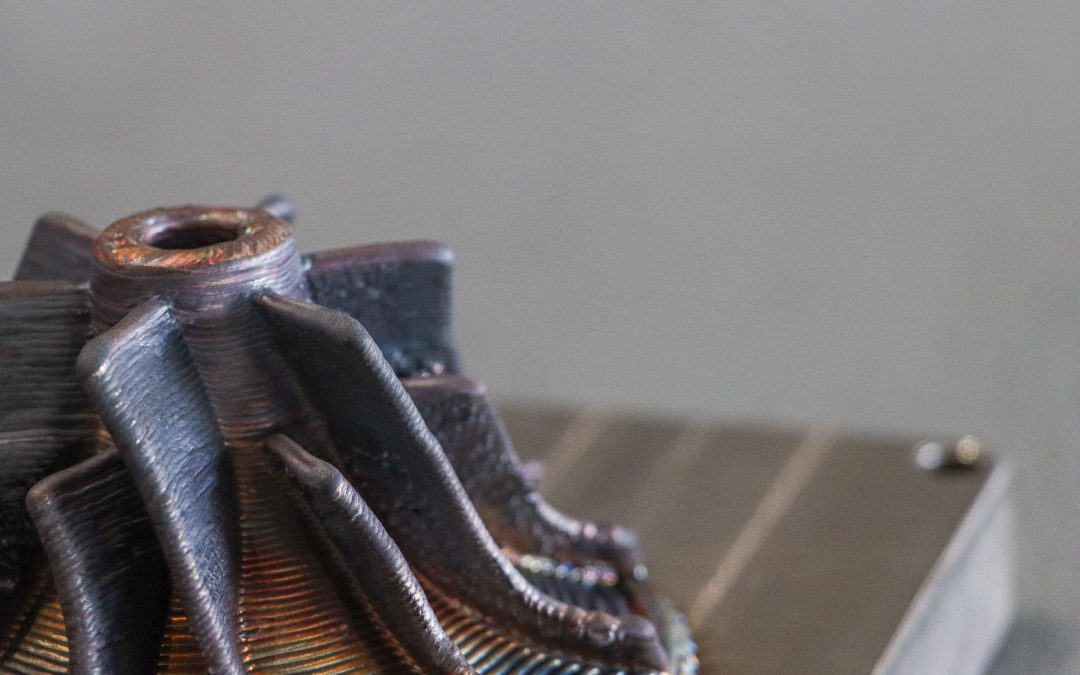

Conformal cooling channels refer to cooling channels that are designed to conform to the shape of a part being manufactured and therefore not possible to produce with traditional manufacturing methods. These cooling channels are typically used in molds for polymer...

by Meltio | Jul 26, 2023 | Knowledge Base

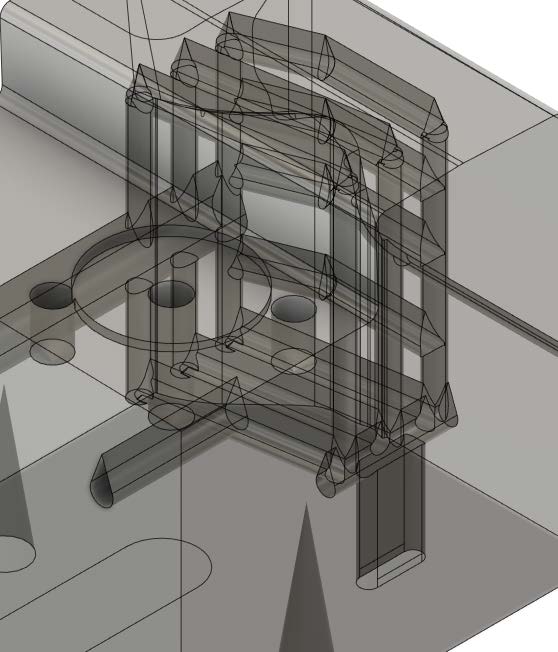

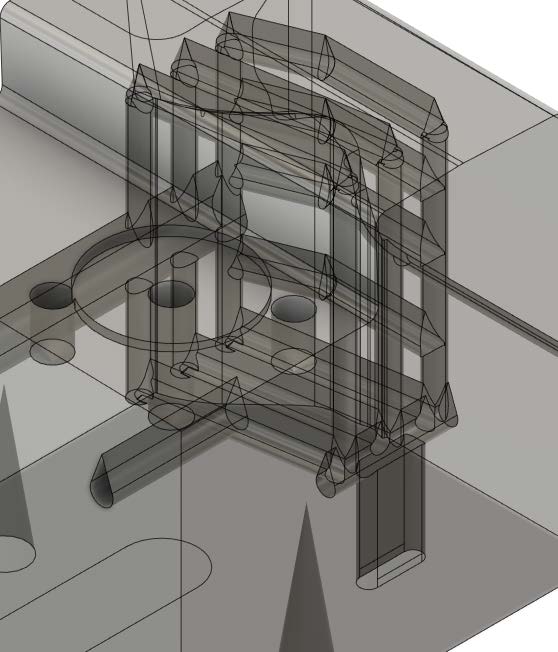

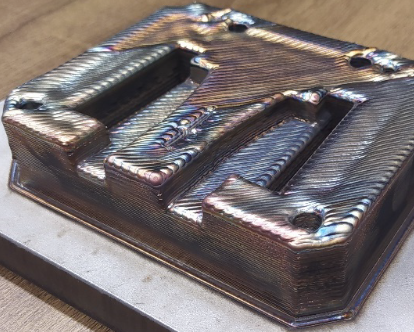

Development Project: Polymer Injection Molding Insert Overview of the complex cooling channels in this project CAD model and sectioned printed sample A large size (about 15.0 kg) polymer injection molding insert was printed on the Meltio M450 unit, with limited DfAM...

by Carolina Vilaplana | Jul 18, 2023 | Knowledge Base

The EU Project imPURE managed to develop a methodology to reuse existing pilot lines for manufacturing medical materials through design and development of modular molds for injection molding. An Additive Manufacturing-enabled approach for fast repurposing of...