Development Project:

Polymer Injection Molding Insert

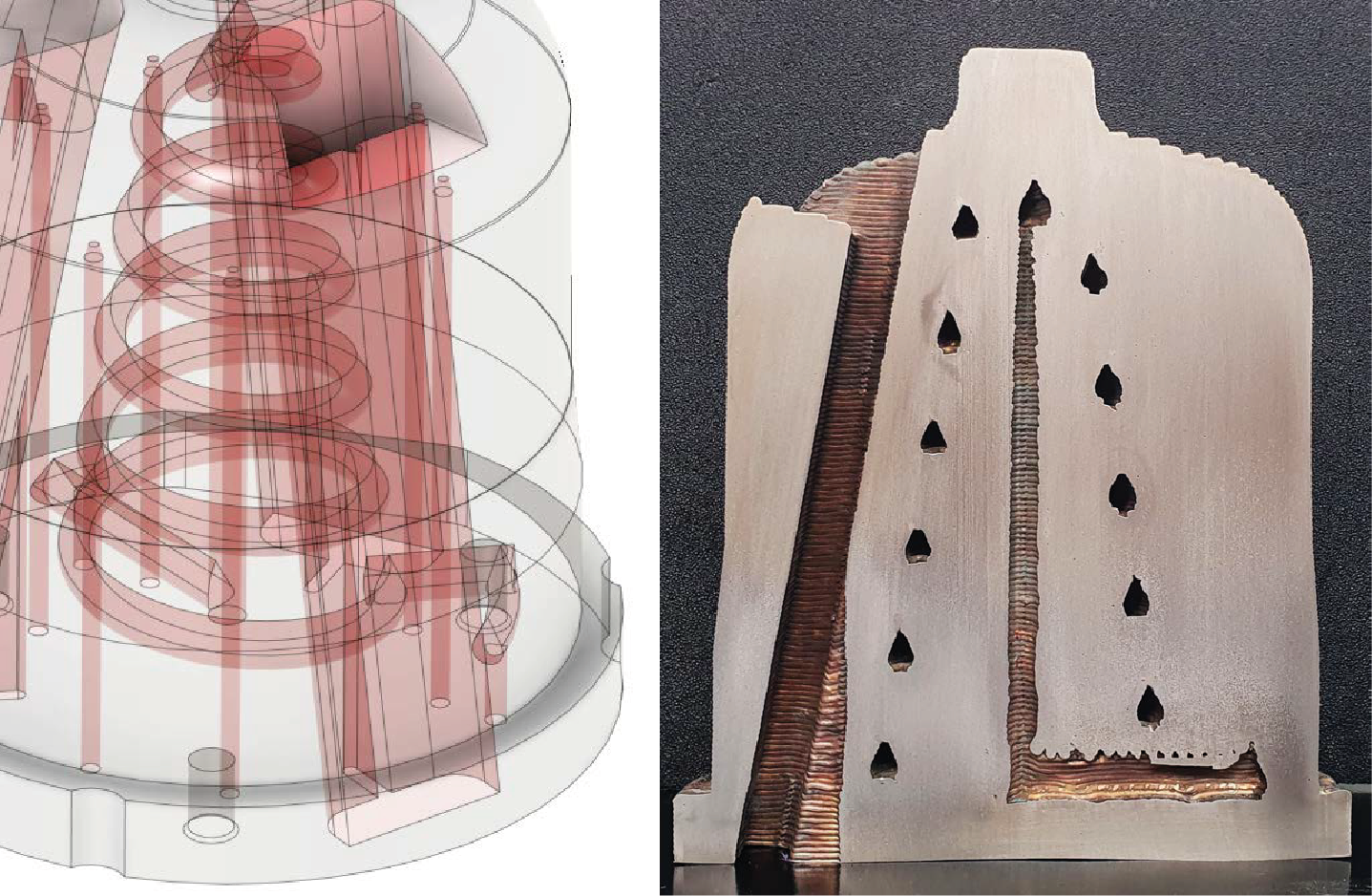

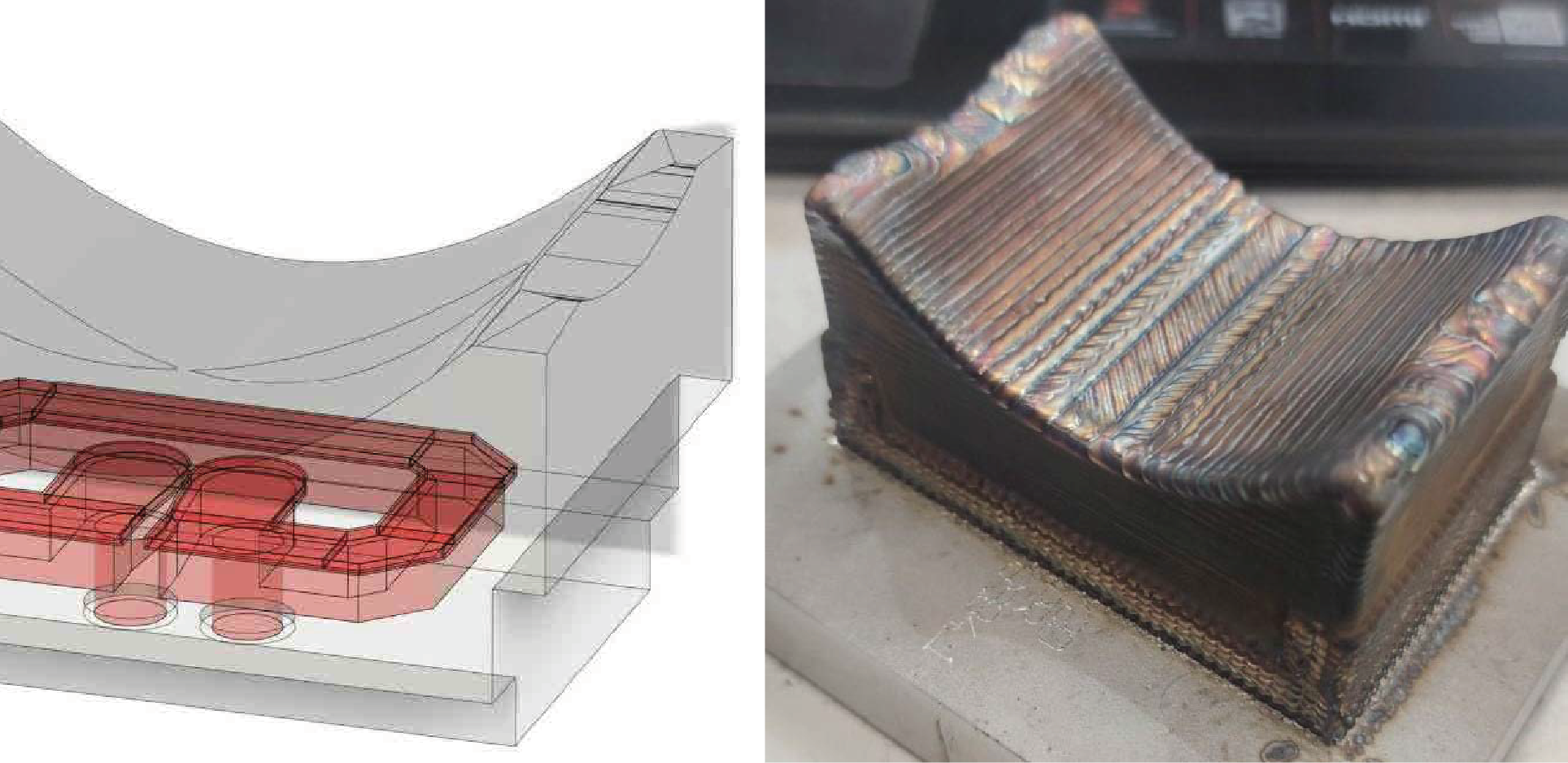

Overview of the complex cooling channels in this project CAD model and sectioned printed sample

A large size (about 15.0 kg) polymer injection molding insert was printed on the Meltio M450 unit, with limited DfAM converting the cooling channels section to teardrop shape. The cooling channels follow a spiral path along the main axis of the part starting from the bottom face.

After printing the insert underwent heat treatment, machining and EDM post processing in order to achieve the surface finish and dimensional accuracy required by the process.

Development Project:

Polymer Injection Molding Insert – Automotive Optical Component

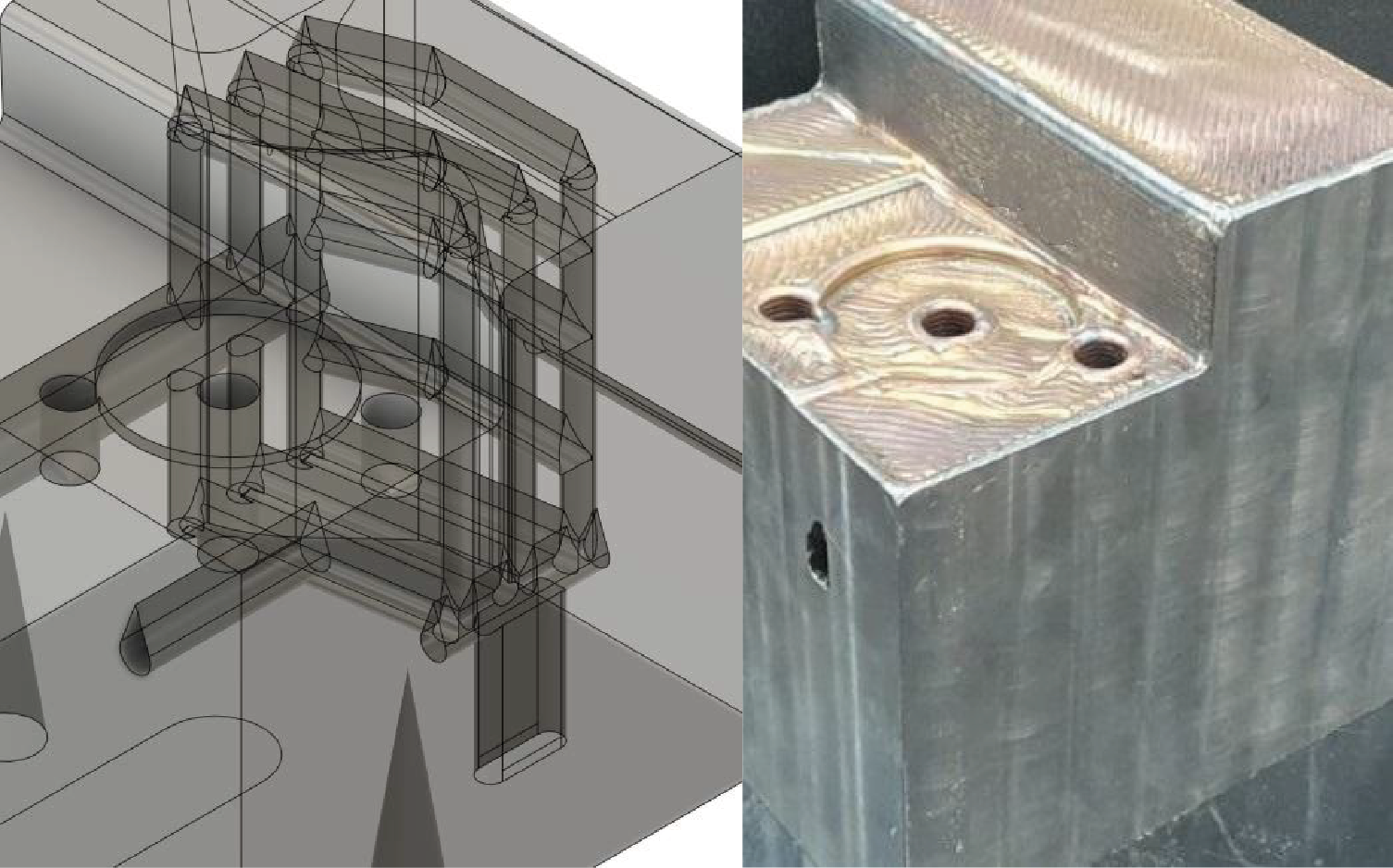

Overview of the complex cooling channels in this project CAD model and sectioned printed sample

AA small (about 1.0 kg) polymer injection molding insert was printed on the Meltio M450 unit, in several iterations: replicating the original, with no cooling, and with cooling channels with a rectangular section. This was made possible with careful parameter development, allowing the possibility of adding conformal cooling to an

existing design not yet cooled.

The printed part underwent machining, polishing and laser texturing of its active surface, showing excellent density and surface quality, a requirement of utmost importance for a tool to manufacture optical components.

Development Project:

Sector of a Die for Hot Stamping of steel sheets

Heat treated, machined and set in operation, the die has logged over 17,000 cycles at the time of writing, with no noticeable signs of wear.