Plastic injection is one of the most affordable and widespread processes for mass production purposes in the industry of thermoplastic polymers. It involves four main stages: (i) injection of molten plastic, (ii) compacting in the mold, (iii) cooling process and (iv) mold ejection. The literature reviews indicate that the cooling stage constitutes approximately 70% to 80% of the total cycle time.

From an economic perspective, the manufacturing of plastic injection molds represents a significant investment. Therefore, a prolonged life cycle is expected to maximize its profitability. The mold should be able to withstand numerous injection cycles without significant degradation in performance or quality.

However, given that the cooling stage is a bottleneck in the injection process, having a highly efficient cooling system within the mold is essential. Inadequate or low-quality cooling can negatively impact product quality, leading to undesirable deformations and shrinkage.

Before you continue: This is a piece of content from the master’s thesis done by Mailan Farias, Applications Engineer at Meltio. Feel free to use it, but please do mention the author. Enjoy!

Managing the Refrigeration Stage

In general, there are two critical parameters for effectively managing the refrigeration stage: cooling time and temperature uniformity on the mold surface. Reducing cooling time is the most desirable outcome to enhance the cooling stage’s performance, as it can decrease the risks of deformation and shrinkage while achieving shorter cycles, allowing for higher production rates.

Cooling performance can be enhanced through material properties and cooling applications. Between these two factors, cooling application is preferable because the mold material properties are mainly decided based on mechanical properties such as strength, and weight, rather than considering thermal conductivity value.

Therefore, in most plastic injection molding applications, the material is not considered a performance-enhancing factor in practical applications, unless otherwise indicated.

Improving Cooling Performance

The complexity of plastic products is defined by challenging curves in the product, which are very difficult to follow with the straight pathways of drilled cooling channels. Consequently, it increases the cooling time and lack of temperature uniformity, leading to low product quality with defective outcomes.

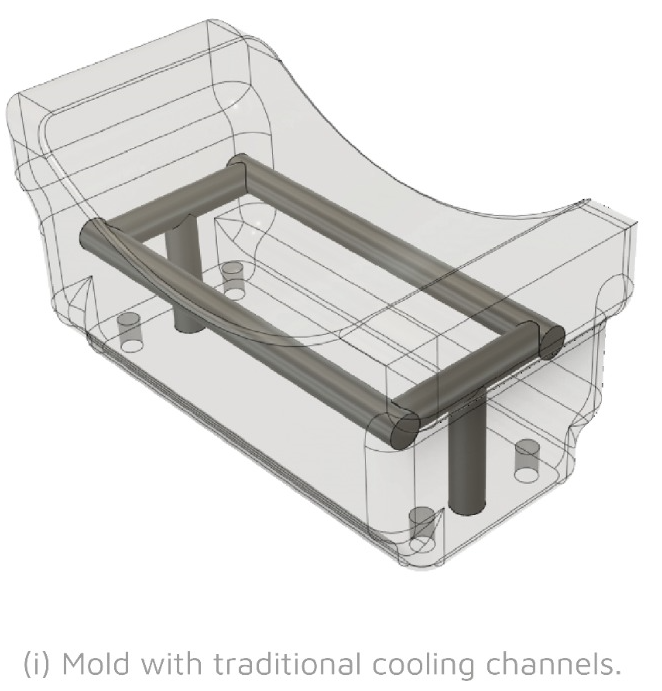

To improve cooling performance, optimal cooling parameters such as channel spacing (distance between two straight-drilled channels), channel diameter, flow rate, and thermal properties of the coolant circulated through the channel can be utilized. However, the mentioned improvement approaches may still be insufficient for complex plastic products due to the design limitations of traditional channels and machining.

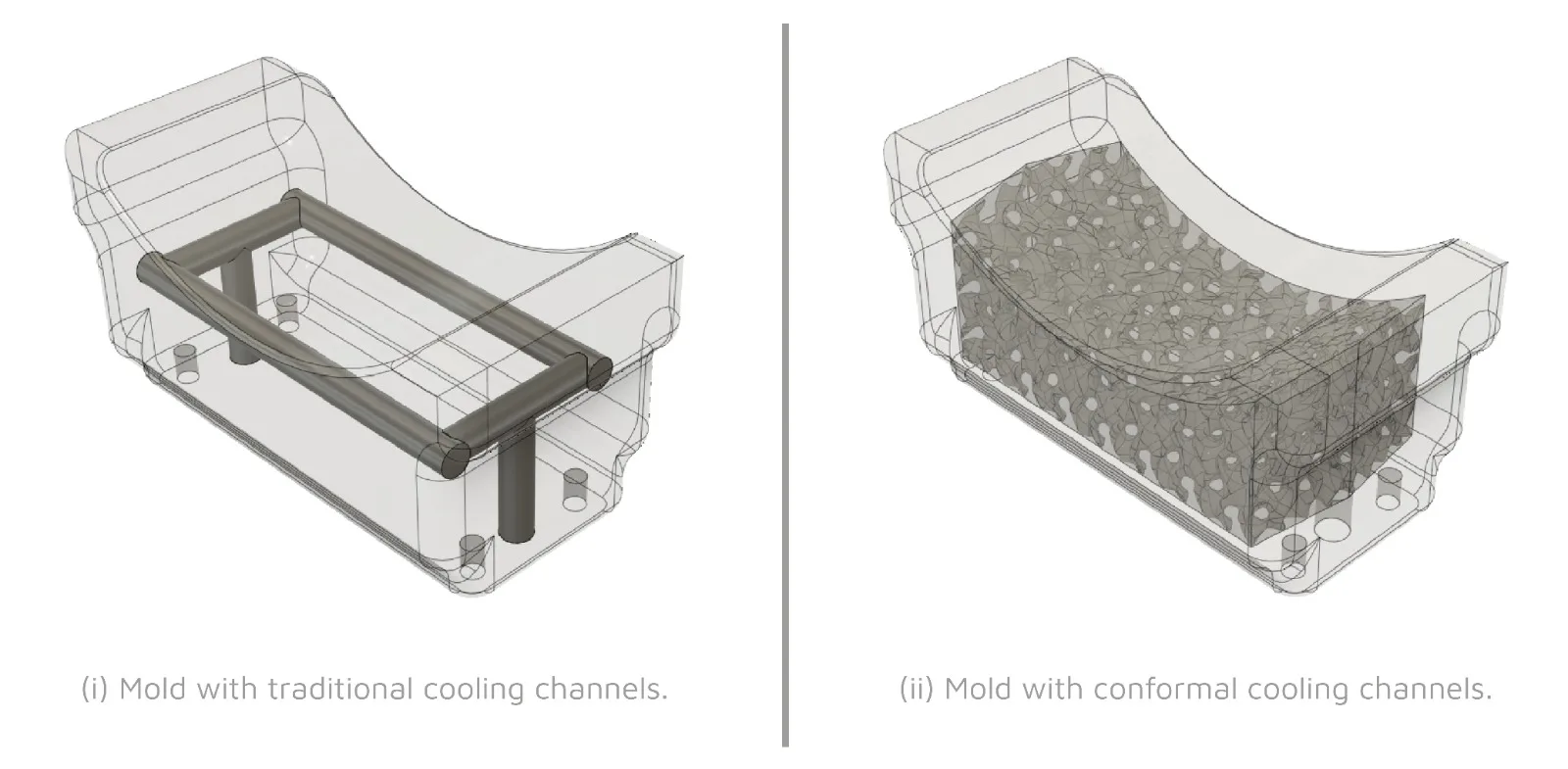

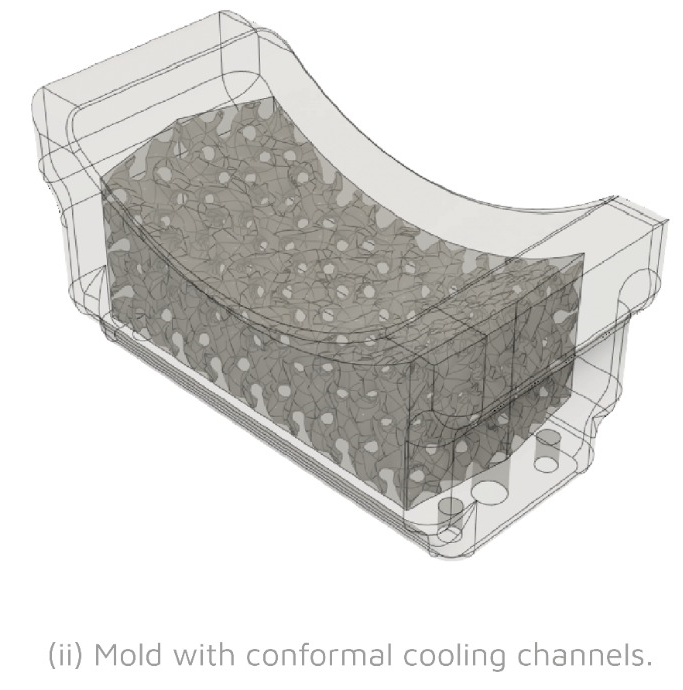

For this reason, conformal cooling channels emerge as a progressive solution to enhance the cooling efficiency in plastic injection processes. Conformal cooling channels are intricately designed to precisely follow the contours of the plastic product in the mold’s geometry.

Meltio’s technology presents a groundbreaking opportunity in the realm of industrial production by unlocking the potential to fabricate plastic injection molds with conformal cooling channels made of lattice structures. The lattice structure not only enhances the overall structural integrity of the molds but also facilitates efficient heat dissipation during the injection molding process.

This advancement allows for precise temperature control, reducing cycle times and enhancing the quality and consistency of molded parts. The convergence of metal additive manufacturing and conformal cooling design represents a paradigm shift in manufacturing, offering increased efficiency, cost-effectiveness, and improved performance in plastic injection molding processes.

TIP: If you want to deep dive into metal 3D printing, read the article about The benefits of a Wire-based Metal 3D Printing process.

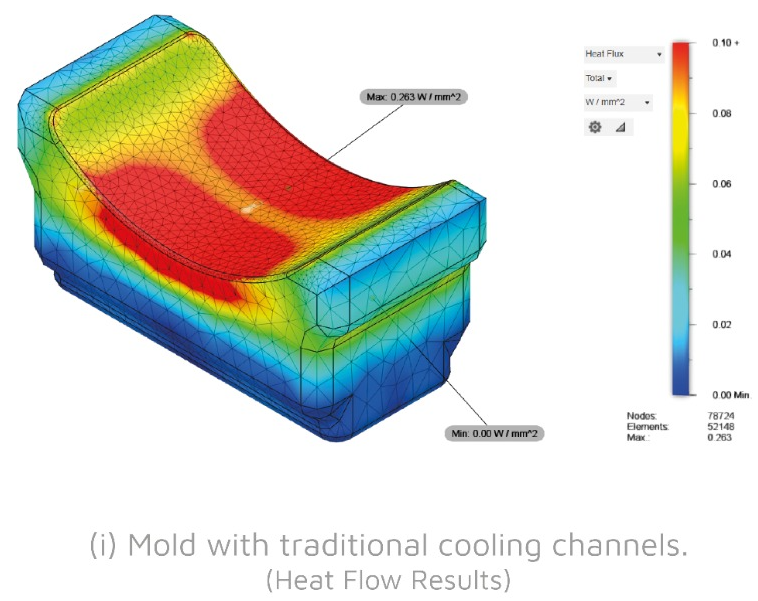

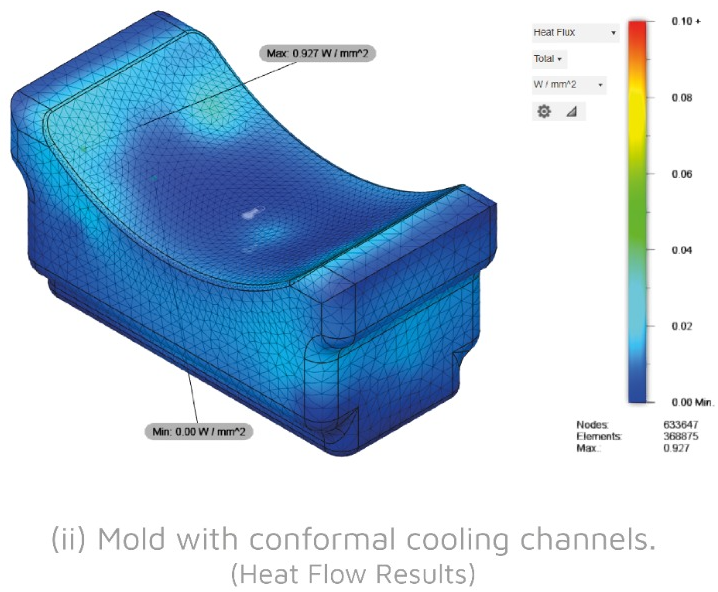

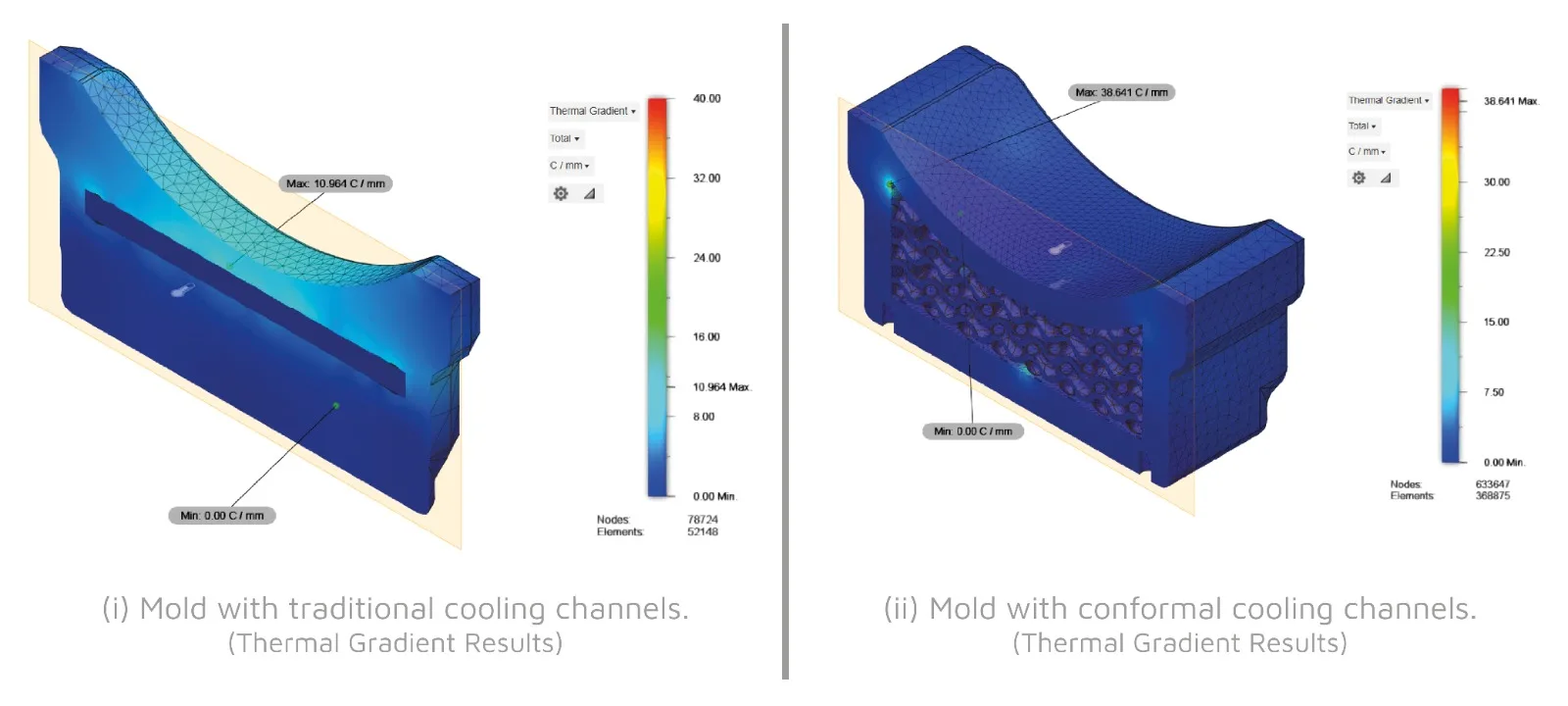

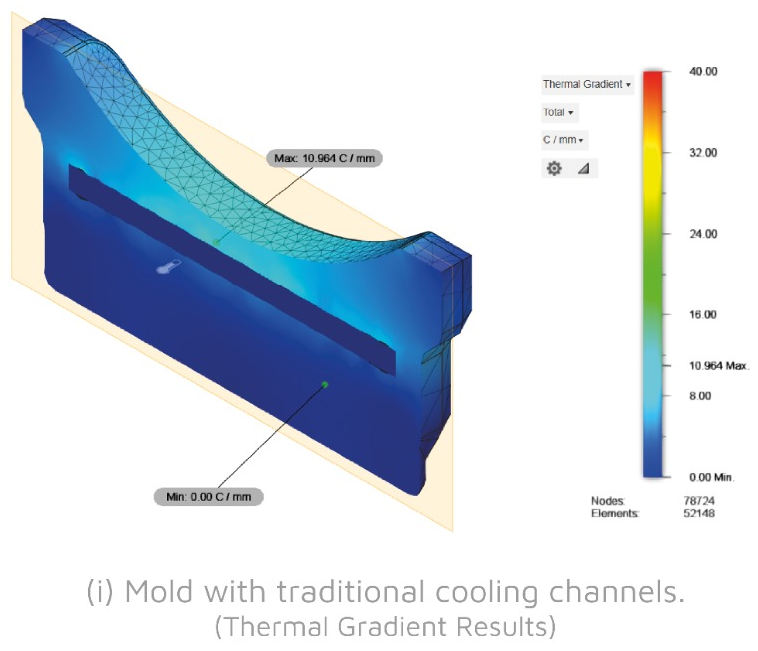

Assessing the Benefits: Thermal Flow Simulation

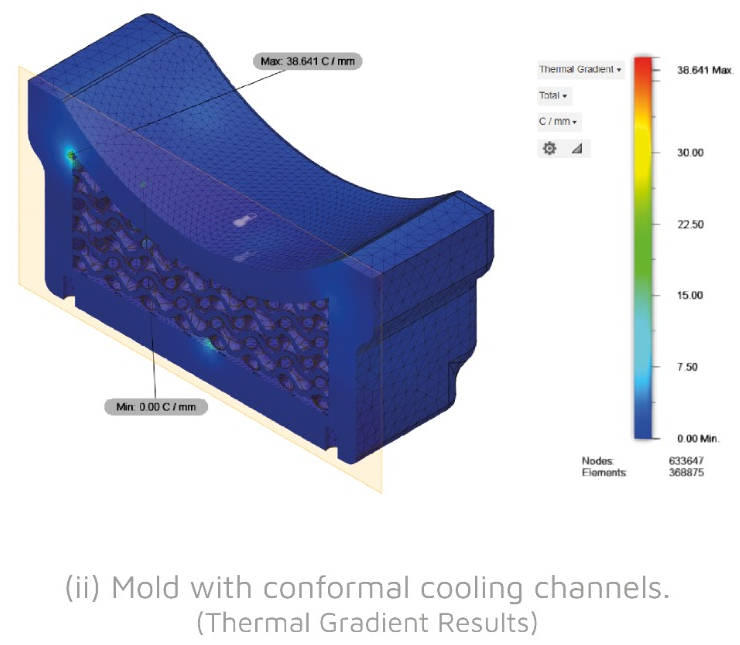

To assess the benefits of a conformal cooling channel in a plastic injection mold that was additively manufactured, a comparative thermal flow simulation was conducted between two mold samples: one featured a traditional cooling channel obtained through hole drilling, while the other incorporated a conformal cooling channel composed of a gyroidal lattice structure. The simulation was performed using Autodesk Fusion 360 software.

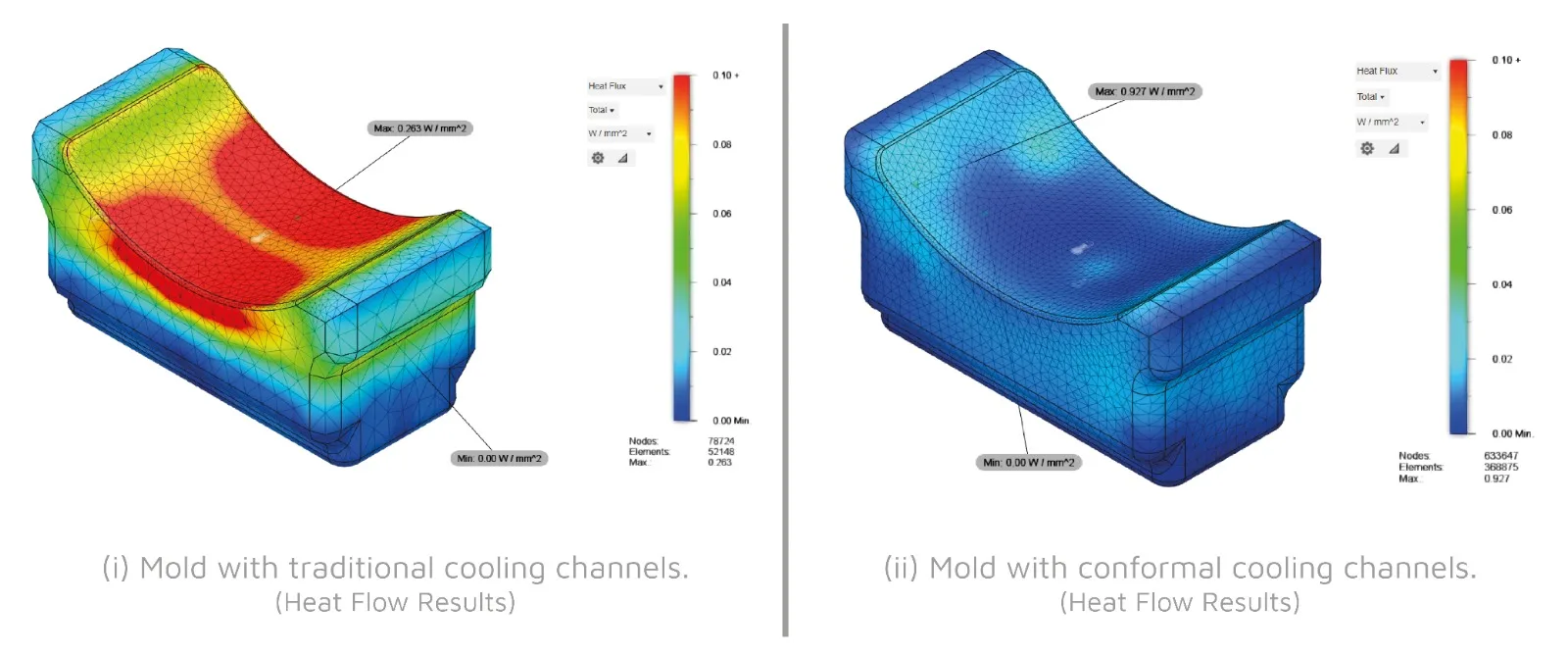

In the thermal flow analysis, the primary focus is on efficiently controlling the mold temperature to optimize the injection process. The thermal loads established for the simulation were as an applied temperature of 80 ºC to the critical zone of the mold, corresponding to the estimated temperature of the injected plastic, and a coolant temperature of 20 ºC applied to the respective cooling channels.

Using identical parameters for both molds uncovered that the mold with a conformal cooling channel demonstrated superior heat flow. In terms of thermal flow, a higher value indicates greater heat transfer, possibly accelerating the transfer from the molten plastic to the coolant in the cooling channel.

This is considered beneficial for rapidly cooling the mold between injection cycles, increasing productivity, and improving the quality of molded parts by controlling plastic solidification. It was observed that the lattice structure was able to increase heat transfer compared to circular channels due to the increased interfacial surface areas and coolant fluid vorticity.

The study also indicated that the mold with conformal cooling channels exhibited a more uniform temperature distribution, as reflected in its predominantly darker blue coloring.

Thanks to increased thermal flow, the conformal channels contribute to maintaining a more constant temperature in the mold, resulting in greater consistency in the quality of molded parts.

Furthermore, it showed significantly lower thermal gradients on the heated critical surface, indicating that this type of conformal cooling channel could be optimal in applications for injection molds, which are high-performance tools where high heat transfer rates and/or thermal balance are critical.

TIP: If you want to expand your knowledge about cooling channels and how they can help and improve your manufacturing capabilities, download this insightful whitepaper about Mold Making with LMD and Dual Wire.

References

1. Santos, Mailan. Fabricación Aditiva En Acero Para Herramientas H11 de Útiles Para Moldeo Por Inyección: Verificación de La Conformidad. 27 Nov. 2023, p. 190.

2. B. B. Kanbur et al., «Metal Additive Manufacturing of Plastic Injection Molds with Conformal Cooling Channels», Polymers (Basel), vol. 14, n.o 3, p. 424, ene. 2022, doi: 10.3390/polym14030424.

3. Plastics Technology, «Why Conformal Cooling Makes Sense. » Accedido: 26 de noviembre de 2023. [En línea]. Disponible en: https://www.ptonline.com/articles/why-conformal-cooling-makes-ense

4. M. Mazur, M. Leary, M. McMillan, J. Elambasseril, y M. Brandt, «SLM additive manufacture of H13 tool steel with conformal cooling and structural lattices», Rapid Prototyp J, vol. 22, n.o 3, pp. 504-518, abr. 2016, doi: 10.1108/RPJ-06-2014-0075.

5. S. Feng, A. M. Kamat, y Y. Pei, «Design and fabrication of conformal cooling channels in molds: Review and progress updates», Int J Heat Mass Transf, vol. 171, p. 121082, jun. 2021, doi: 10.1016/j.ijheatmasstransfer.2021.121082.