Laser Metal Deposition (LMD)—often categorized under Directed Energy Deposition (DED)—is an additive manufacturing process where a focused energy source (laser) creates a melt pool on a metallic substrate, into which feedstock (wire or powder) is simultaneously fed and melted.

While the technology shares roots with laser welding, modern LMD has evolved into a high-precision manufacturing solution that bridges the gap between the high cost of Selective Laser Melting (SLM) and the lower resolution of Wire Arc Additive Manufacturing (WAAM).

This guide dissects the mechanics, material benefits, and industrial position of Wire-Laser Metal Deposition (W-LMD).

1. How LMD works

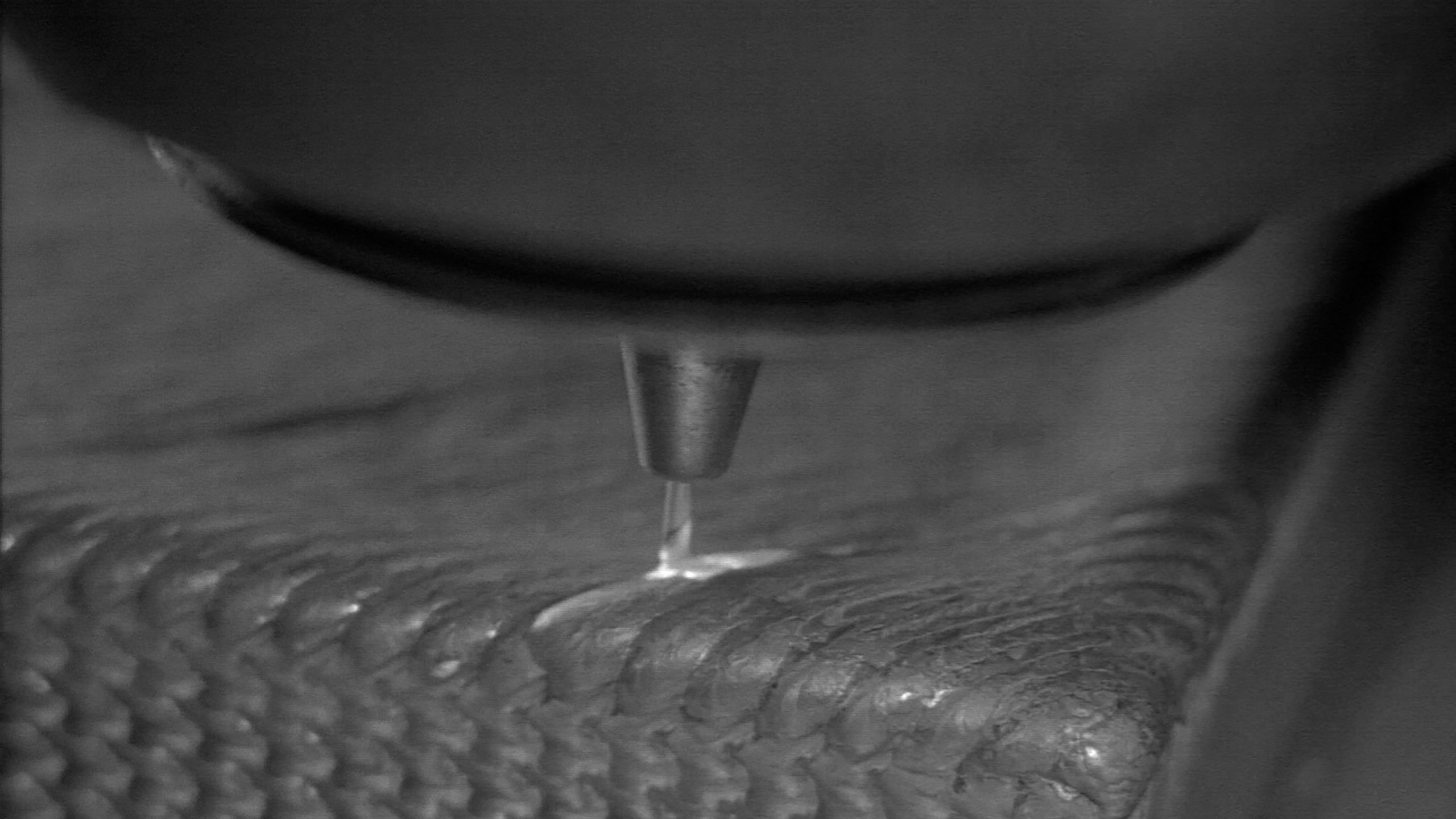

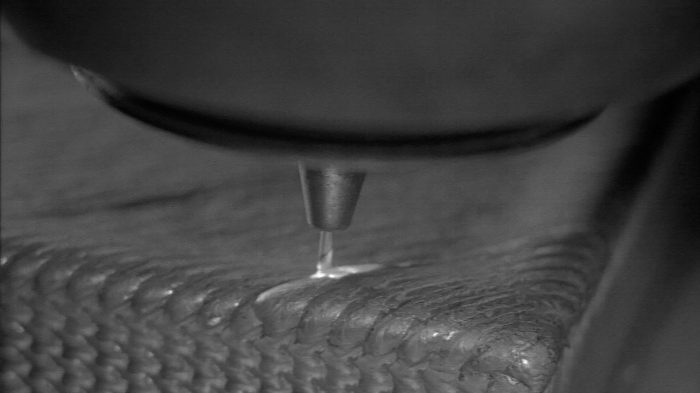

At its core, LMD is a «micro-welding» process automated in three or more dimensions. Unlike powder bed systems that spread material across a flat plate, LMD is free-form.

The coaxial advantage

In the specific configuration used by Meltio, the process relies on a coaxial deposition head.

The beam: Multiple lasers (often fiber-coupled diode lasers) are angled to converge at a single point (the focal point).

The feedstock: Metal wire is fed through the center of this laser ring.

The result: Because the lasers surround the wire, the heat input is isotropic. You can print in any direction (X, Y, or complex 5-axis curves) without reorienting the tool head. This eliminates the «trailing edge» issues found in standard arc welding.

2. LMD vs. WAAM vs. SLM: The technical comparison

For an industrial CTO, the choice of technology comes down to the «Iron Triangle»: Speed, Resolution, and Cost.

| Feature | Meltio (Wire-LMD) | WAAM (Arc) | SLM (Powder Bed) |

| Feedstock | Standard Welding Wire | Standard Welding Wire | Proprietary Metal Powder |

| Heat Source | Multi-Laser | Electric Arc / Plasma | Single/Multi-Laser |

| Resolution | Medium-High (Near-Net) | Low (Rough) | Very High (Precision) |

| Heat Input | Low (Controlled HAZ) | High (High Distortion) | Low |

| Deposition Rate | Moderate | High | Low |

| Safety | Clean (No powder) | Moderate (Fumes) | Hazardous (Reactive Powder) |

| Primary Use | Functional Parts, Cladding | Large Structural Parts | Small Complex Parts |

3. Why Wire-Laser?

4. Material physics: Why wire matters

In LMD, the feedstock dictates the process stability. Meltio focuses on wire for thermodynamic reasons:

100% Material efficiency

Unlike powder, where up to 90% of the material is unfused and must be recycled, 100% of the wire that enters the melt pool becomes the part.

Surface tension and density

Wire is solid. It does not carry the entrapped gas porosity often found in gas-atomized powders. This results in superior fatigue resistance in the final part.

The chill effect

The LMD process allows for rapid cooling rates. This creates a fine micro-crystalline structure, often resulting in mechanical properties that exceed those of cast equivalents and rival forgings.

TIP: Read the full materials guide HERE.

5. Key applications of LMD

1. Near-Net Shape Manufacturing

Instead of machining a part from a solid block (where you might waste 80% of the material as chips), LMD prints a shape very close to the final geometry. You only machine the critical tolerance surfaces.

2. Mold Repair & Cladding

Because LMD is a DED process, it can print onto existing parts.

Repair: Add material to worn dies or broken shafts.

Cladding: Deposit a hard-wearing material (like Stellite or Inconel) onto a cheap steel shaft to improve wear resistance without the cost of making the whole part out of superalloy.

3. Dual-Wire Manufacturing

Advanced LMD heads can switch wires mid-print. You can print the core of a propeller in simple mild steel and switch to a corrosion-resistant stainless steel for the outer skin, creating a functionally graded material.

6. The industrial reality

Laser Metal Deposition is no longer a research topic; it is a factory-floor reality. It removes the safety hazards of powder and the imprecision of arc welding. For industries requiring density, traceability, and cost-efficiency—such as Automotive, Defense, and Marine—Wire-LMD is the logical successor to traditional casting for low-to-medium volume production.