In the defense sector, readiness is everything. Whether it’s a naval vessel, a mobile unit, or a mission-critical facility, downtime is not an option. Yet, one of the biggest threats to operational continuity is the failure of legacy components — parts that are no longer manufactured, difficult to source, or simply not robust enough for today’s demands.

That’s where Meltio steps in.

By harnessing the power of wire-laser metal additive manufacturing, Meltio’s technology is transforming how the defense industry approaches maintenance, repair, and production of essential components — delivering solutions that are faster, smarter, and built for resilience.

1. The issue with legacy parts and supply chain fragility

From impellers and diffusers to eductors and structural parts, many components used in military and defense applications are decades old. Traditional manufacturing methods — like casting or subtractive machining — struggle to keep pace when:

The original designs or tooling are lost

Replacement parts have long lead times or are cost-prohibitive

These challenges are compounded by the need for quick turnaround, reliable performance, and adaptable solutions, especially in high-stakes defense environments.

2. Enhancing operational availability with Meltio’s technology

Meltio’s Directed Energy Deposition (DED) systems, including the Meltio M600 metal 3D printer and the robotic and CNC integration kits, allow defense users to manufacture complex metal parts on-demand, on-site, and with minimal redesign.

The result is a significant shift in how parts are sourced, repaired, and even improved.

Replacement parts at point-of-use

“If the crew had to rely on a replacement part without using additive manufacturing, it would have taken weeks or months. With this technology, we’ll have the new component printed and ready for installation before the order for a replacement would be completed”.

Staff Sgt. Jordan Blake, a member of the Marine Innovation Unit.

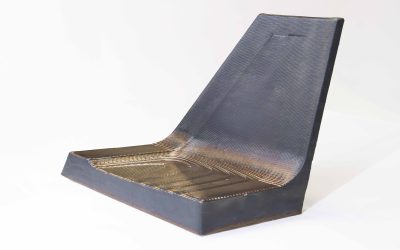

Use case 1: Stainless steel diffuser

A stainless steel diffuser, essential for pressure recovery at a pump outlet, was rendered inoperable after years of hydraulic abrasion and galvanic corrosion.

Read the full use case here.

Problem:

No manufacturer could reproduce it affordably or quickly.

Meltio solution:

Using Meltio’s technology, the component was printed in two parts, simplifying the build and allowing for improved wall thickness and mechanical performance. Redundant features were removed, and internal geometries preserved.

Result:

Enhanced durability

Delivered faster without tooling

Use Case 2: Eductor

Eductors, which leverage fluid flow to drive secondary movement without additional pumps, are often cast in CuSn or CuNi alloys.

Read the full use case here.

Problem:

These parts wear quickly and are challenging to inspect or replace predictively.

Meltio solution:

With Meltio, the eductor was reimagined. Printed in 316L stainless steel, the new design featured optimized sub-components for post-processing and a second-generation model specifically tailored for additive:

Result:

Reduced overhangs and simplified mounting

Use Case 3: Close Impeller

Fire protection systems rely on closed impellers that spin constantly.

Read the full use case here.

Problem:

In traditional cast bronze, these parts face vibration, cavitation, and corrosion, often leading to sudden failure.

Meltio solution:

Meltio’s additive approach rebuilt the impeller in 316L stainless steel, using a Radial 360 print strategy with custom supports.

Result:

Split-build approach

Republic of Korea Marine Corps

3. Why Defense chooses Meltio

With threats evolving and systems aging, defense agencies worldwide are turning to additive manufacturing not just to replace the past, but to build a more agile and self-sufficient future.

Meltio’s technology isn’t just about making parts — it’s about ensuring mission readiness, extending the lifecycle of critical systems, and enabling a shift toward digital manufacturing strategies that empower teams in the field, at sea, or in the supply depot.

Whether it’s modernizing the fleet, maintaining readiness, or reinforcing infrastructure, Meltio is proud to stand with the defense sector — delivering innovation, one layer at a time.

Speed: From months to days — parts can be produced on-site or locally, slashing lead times.

Resilience: Advanced materials like stainless steel 316L outperform traditional alloys in corrosive or high-vibration environments.

Adaptability: Designs are optimized for printability, performance, and ease of post-processing.

Sustainability: Repair or reproduce only what’s needed, minimizing waste and extending the life of critical systems.

Readiness: When failure isn’t an option, Meltio provides the tools to ensure operational continuity.

4. Trusted by

To know more how Meltio is helping armed forces worldwide, click HERE