Thus, the French Navy engineers from the logistics base and arsenal of Toulon (southern France) received from the Charles de Gaulle aircraft carrier the characteristics and properties of the metal part they needed and in tele-assistance mode the Meltio M450 from land processed the information and manufactured with Meltio additive technology the required part, being this test successful.

The objective was to solve immediate repair and fabrication needs of stainless steel parts on board with its unique additive manufacturing technology.

This case study has been developed thanks to the collaboration with our trusted sales partner Multistation.

Evolution of 3D printing in the maritime and naval sector: Case study

Additive manufacturing in the marine and naval defense industry has progressed tremendously in recent years and for different purposes beyond prototyping. From ship propellers, river shuttles and cable glands to submarine valves, 3D printing applications for end-use and production parts are gaining ground. In addition, having a Meltio 3D printer offers the unique advantage of being able to manufacture parts on-site on demand or repair them, depending on requirements.

In France, the French Navy has reported how Meltio’s metal 3D printing enabled them to resolve a breakdown on the Charles de Gaulle aircraft carrier. This ship was conducting an operational maintenance exercise in a high-intensity environment, organized by the Fleet Support Service (SSF), which was taking place in the workshops of the Navy’s logistics department in Toulon.

The main objective of the exercise was to ensure that the procedures and solutions used to repair damage to the ships were robust and effective enough to function in real combat or operational conditions. They therefore wanted to test and ensure that their repair methods were effective and reliable even in high-pressure and emergency situations.

Photos: Marie Bailly / French Navy / Defense //Jeremy Vacelet / French Navy

Credits: SSF – Service Soutien de la Flotte

“We are at an initial point of use of the Meltio M450 for the Marine Nationale. Its state of use is experimental. The French Navy uses the Meltio M450 on land. The machine is installed at our naval base, located in the city of Toulon. After months of previous testing at our technology center in Toulouse (DGA/Techniques Aéronautiques), South of France, to test Meltio’s DED wire-laser technology, the printer was approved for transfer to Toulon. The main objective of this transfer is to test this machine for the needs of the Marine ships that are sailing with their repair and manufacturing needs in different metallic materials, mainly stainless steels and inconel, for which the Meltio M450 seems efficient in the result of the parts obtained.”

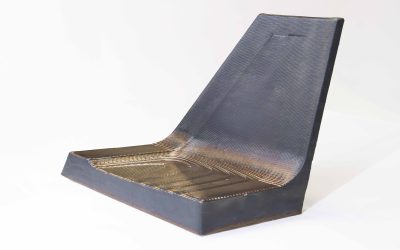

In this case, Meltio’s solution enabled a 3D metal replacement spray plate for a ballast air compressor (DBAC) to be fabricated in just 5 days, instead of potentially taking weeks to source through conventional Navy supply channels.

This part is used to force pressurized air through saltwater tanks and discharge accumulated saltwater. The tanks are filled to reduce the ship’s draft in amphibious operations. Fabricating the metal sprayer plate offshore allowed the ship to reduce the time required to obtain a replacement assembly.

In addition, its manufacture posed a technological challenge for the French engineering team since the part to be manufactured had to be made of metal, a first for the department, which had never used this manufacturing process before.

Photos: Marie Bailly / French Navy / Defense //Jeremy Vacelet / French Navy

Credits: SSF – Service Soutien de la Flotte

Benefits of Meltio 3D Printing for the Defense sector

Meltio 3D printing has had a significant impact on various industries, and the marine and shipbuilding sector is no exception. Meltio, with its advanced 3D printing solutions, has contributed considerably to the evolution in manufacturing processes and, in addition, they present numerous advantages:

Customized component manufacturing

Meltio enables the manufacturing of customized components on demand. This is especially useful for parts that are difficult to source or require long lead times. (e.g. obsolete military parts or parts in need of repair).

With 3D printing, it is possible to produce these components quickly and economically, thus reducing downtime and associated costs. In addition, 3D printing allows the creation of complex geometries that would be impossible or very costly to manufacture using traditional methods.

In the end, the supply chain is efficient, as highlighted by the French Navy: “These parts are manufactured at low production cost per cubic centimeter. What’s more, the speed of execution and efficiency are such that production is more competitive with traditional manufacturing methods.”

Weight and material reduction

One of the main advantages of 3D printing is the ability to optimize part design to reduce weight without compromising structural strength. Meltio makes it possible to manufacture lighter parts using less material, which is especially beneficial for the marine industry.

French Navy engineer working on the Meltio metal 3D printed part.

Photos: Marie Bailly / French Navy / Defense //Jeremy Vacelet / French Navy

Credits: SSF – Service Soutien de la Flotte

Rapid prototyping

The product development cycle is significantly accelerated, enabling faster and more efficient innovation. For example, the fabrication of the metal plate of the offshore sprayer, a ballast air compressor (DBAC), which was done aboard the USS Bataan, allowed the ship to reduce the time required to obtain a replacement assembly, which was a total of 5 days.

Repair and maintenance

Meltio’s technology is also used for repair and maintenance of existing components. Instead of replacing entire parts, it is possible to repair only the damaged areas using 3D printing, resulting in time and cost savings. In addition, this technology offers the advantage of allowing on-site repairs, which is crucial for vessels that cannot afford long periods of downtime or are in remote locations where stopping is not an option to contemplate.

“The introduction of additive manufacturing (AM) into naval operations supports readiness and self-sufficiency,” states Rear Adm. Brendan McLane, commander, Naval Surface Force Atlantic. “These printers have the ability to help the Navy overcome both obsolescence issues for ships and systems that have service lives measured in decades and directly contribute to enhanced operational availability of our systems and ships,” says NAVSEA Chief Engineer Rear Adm. Jason Lloyd.

Developed materials

Meltio has developed solutions that allow the use of a wide range of materials, including advanced metals such as stainless steel, titanium or nickel alloys. Recently, we have started to develop the parameters and test the Marine Bronze with the new Meltio M600 machine, given the good results that bronze alloys have had with our technology.

These materials are essential for marine applications due to their high corrosion resistance and durability in harsh environments. In particular, marine bronze has natural antimicrobial properties, which help prevent the growth of bacteria and other microorganisms on its surface. It also has excellent wear resistance and possesses excellent thermal and electrical conductivity.

The ability to print with these materials has opened up new possibilities for the design and manufacture of marine components. In addition, parts made from our materials have a high density, specifically 99.99 %, as reported by the navy: “The use of 3D metal printing makes it possible to supply fully dense parts for a variety of industrial applications.”

TIP: Discover the full range of Meltio Materials and its properties by visiting the Meltio Materials page.

Photos: Marie Bailly / French Navy / Defense //Jeremy Vacelet / French Navy

Credits: SSF – Service Soutien de la Flotte

The trusted choice for armies around the world

This is not the first time that a military has made use of Meltio’s 3D printing technology, as both the US and Spanish militaries are already using it.

A printed part was made aboard the US Navy’s USS Bataan demonstrating the successful results of Meltio’s hybrid system installed aboard this warship, in this case on a computerized machine or CNC milling machine. The ability to obtain spare parts at sea is a challenge, especially considering that space is at a premium and many decades-old parts are nearly obsolete. The U.S. Navy ship USS Bataan is addressing the problem by being the first to deploy a hybrid manufacturing system that includes Meltio’s head on a milling machine and provides sailors with industrial-grade manufacturing capabilities.

Meltio’s solution enabled a 3D metal replacement sprayer plate for a ballast air compressor (DBAC) to be manufactured in just 5 days, instead of taking weeks, potentially, to source through conventional Navy supply channels.

This milestone was awarded the XtechInternational award, recognizing Meltio as a “strategic technology partner” in that country’s current and future military and security development plans.

In the case of Spain, Soluciones Sicnova, a distributor in Spain of Meltio solutions, has signed an agreement with the Ministry of Defense to implement in four years “joint actions for the development and execution of a digitalization strategy that simplifies the manufacture of parts and spare parts in their supply chains”. Defense aims to improve the supply and logistics chains of the Armed Forces, increase the operability of fleets, resources in operations and avoid problems related to the obsolescence of parts and pieces, as well as increase their useful life through a strategy of design and additive manufacturing that allows the development and manufacture of parts, spare parts and tools.

The French Navy is already considering including it in upcoming real-life exercises and in the future could even incorporate it on board ships in its fleet.

Thus, France, after the United States and Spain, is the third country to successfully integrate Meltio technology in its tests to adopt Spanish technology. Other armies continue to advance in their validation processes for this technology.