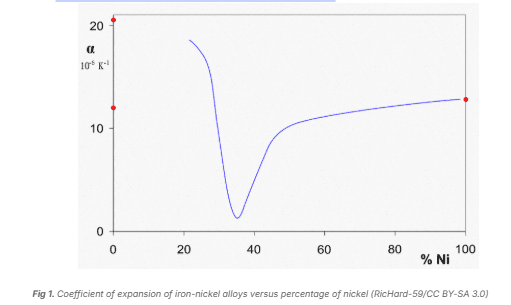

In the world of materials science, few alloys have a legacy as rich as Invar. It is a special blend of iron and nickel celebrated for a unique characteristic: an extremely low coefficient of thermal expansion. This means it barely changes size with temperature variations.

While most metals expand when heated and contract when cooled, Invar’s stability revolutionized high-precision mechanisms and continues to be a key material in modern engineering.

Today, thanks to Meltio’s metal additive manufacturing technology, this historic material is more accessible and versatile than ever, overcoming past manufacturing hurdles.

1. Material overview

Invar is a special alloy of iron and nickel, renowned for its extremely low thermal expansion: it hardly changes in size when temperature varies. This property was revolutionary since most metals expand when heated and contract when cooled, which compromised mechanisms requiring high precision. A key example was pendulum clocks and marine chronometers, where even the smallest variation in length could lead to significant errors, especially in maritime navigation.

The discovery of the right composition, Invar 36, allowed instruments made from this alloy to maintain accuracy from the tropics to the poles. In 1897, Charles-Édouard Guillaume solved the long-standing problem of thermal expansion using a material much cheaper and more accessible than platinum-iridium, which had been used until then. Although Invar lacked the same mechanical or chemical resistance, its stability against temperature changes was unmatched and revolutionized timekeeping and navigation.

Today, metal additive manufacturing has made Invar easier to shape and integrate into demanding applications, overcoming the machining difficulties it once posed. Thus, this historic material not only transformed horology and navigation but continues to play a key role in modern engineering.

2. Invar 36

This alloy has gained a reputation for enabling processes that would be difficult or too costly with other alloys. It allows manufacturers to design tooling with complex shapes that remain reliable over long production cycles, and it has become especially attractive to print with Meltio for companies in the instrumentation, semiconductor and composite moulding industries, as well as aerospace.

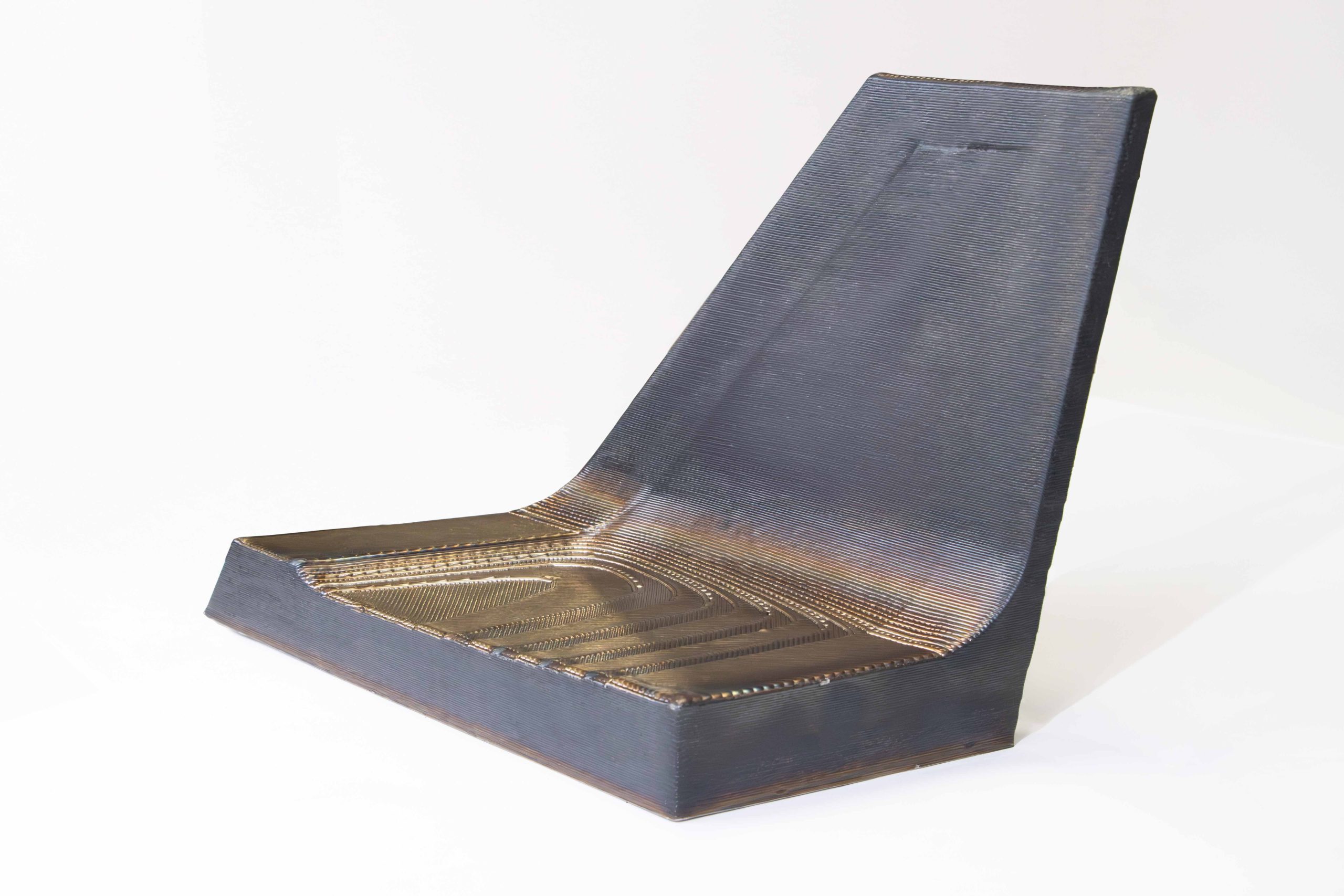

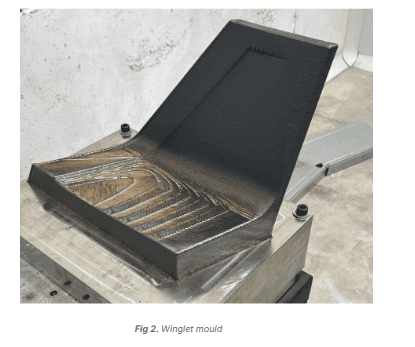

One of our main applications for this material is a Winglet Mould, printed with the Engine Robot. These parts need to preserve their geometry throughout repeated heating cycles during composite curing. By manufacturing the tool in Invar 36, the final part maintains the required aerodynamic shape while also reducing production times and material waste compared to conventional approaches.

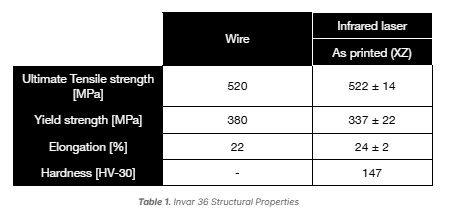

Below, it is provided a series of Structural Properties for this material.

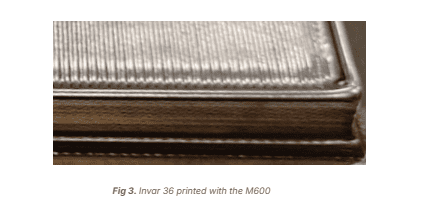

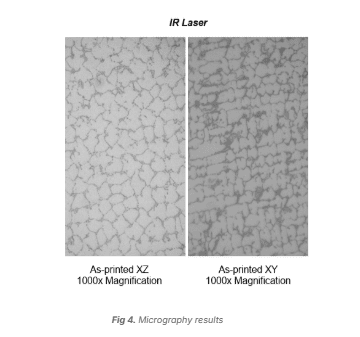

In terms of productivity, Invar 36 deposition rates can go up to 248.5 g/h with the 1 kW Blue Laser. The micrography results were obtained by an external laboratory from a 10x10x60 mm sample extracted from a printed block, following ASTM standards and ensuring proper preparation and examination of the microstructure.

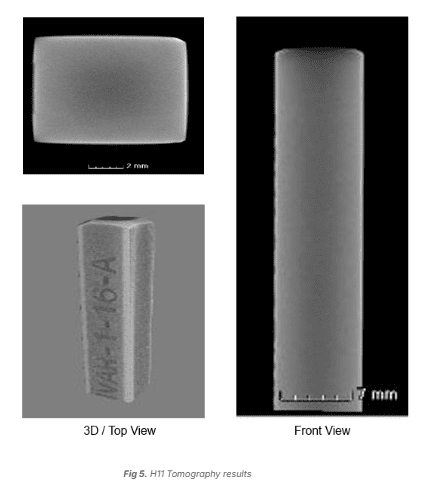

On the other hand, regarding tomography tests, the results of the CT scan of a sample using an infrared laser are attached, showing no detectable voids or defects, with a resolution of 24 μm per pixel.

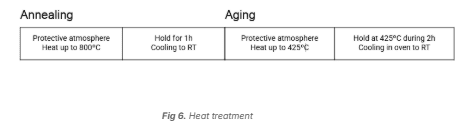

Owing to the use of Invar in precision components, it is often recommended to subject it to an annealing heat-treatment after 3D printing. This is necessary as the printing process introduces residual stresses, which affects the material’s performance. After annealing, the sample should pass through an aging process to improve and achieve suitable mechanical properties.

3. Why choose Meltio’s Invar

Overcome manufacturing hurdles

Meltio’s technology sidesteps the traditional difficulties of machining Invar, enabling the creation of intricate parts that would otherwise be too costly or complex to produce.

Freedom to design complex tooling

Manufacturers can design and print tools with complex shapes that remain reliable and dimensionally stable over long production cycles.

High quality, dense parts

Tomography tests on parts printed with an infrared laser show no detectable voids or defects, ensuring the final component is solid and reliable for demanding applications.

Productivity

With deposition rates reaching up to 248.5 g/h using the 1 kW Blue Laser, Meltio enables the efficient production of robust Invar components.

TIP: Know more about compatible and Meltio materials by downloading the Meltio Materials Printable List.

4. Main applications for Invar 36

The unique stability of Invar 36, combined with the design freedom offered by Meltio, makes it especially attractive for several high-tech industries. The primary sectors benefiting from this technology include:

- Aerospace

- Instrumentation

- Semiconductor industry

- Composite moulding

The W-LMD technology produces parts with exceptional microstructure and a density of 99.998%, surpassing the properties of castings and rivaling those of forgings.

5. Guaranteed performance and quality

Invar is more than just a material; it’s a testament to innovation. Its discovery solved a critical challenge in the history of science and navigation, and its story continues today. With Meltio’s advanced metal 3D printing technology, Invar 36 has been unlocked for a new generation of engineers and designers. By overcoming traditional manufacturing barriers, we are not only preserving the legacy of this remarkable alloy but also expanding its application in the most demanding industries of the future.

TIP: Discover more materials in the Materials Guide.