In this blog, we’ll look at the advantages of Meltio’s process compared to powder-based AM technologies. While these powder processes offer numerous advantages, such as high resolution and the ability to work with a growing range of materials, they also come with their own set of challenges.

We’ll explore the limitations and potential drawbacks of using powder-based technologies in manufacturing. Understanding these challenges is essential for evaluating the true potential of powder AM processes and finding ways to optimize their performance in real-world applications.

1. Powder-based AM technologies: Powder Bed Fusion and Powder DED

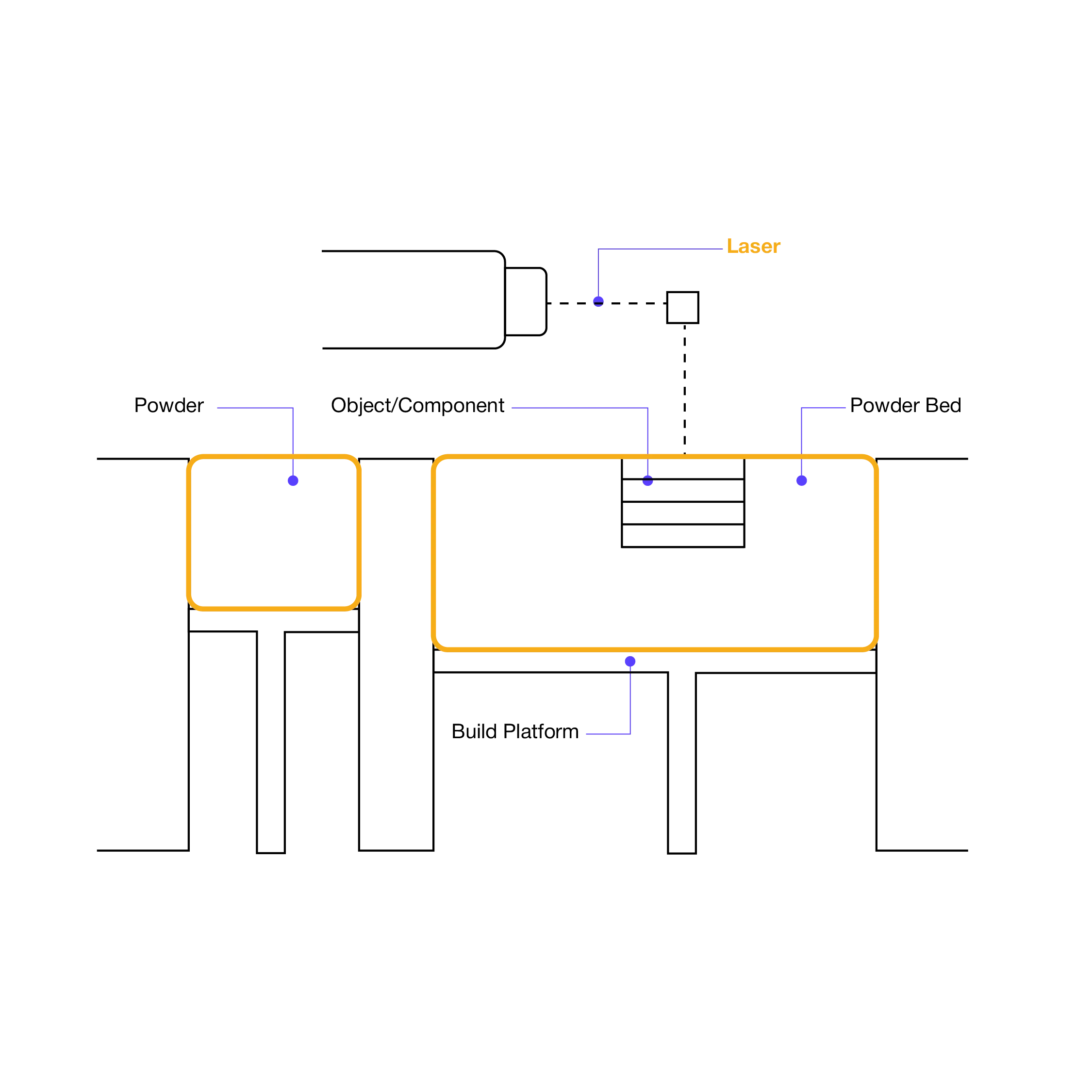

Within the powder technologies, among those using lasers, we highlight Powder-Bed-Fusion (PBF) and Powder DED.

Powder Bed Fusion (PBF) has emerged as one of the most prominent additive manufacturing processes, widely adopted for creating 3D objects in engineering and biomedical applications. Its advantage lies in the ability to manufacture parts layer by layer using a single material, allowing for the fabrication of intricate geometries with customized designs tailored for specific industrial needs.

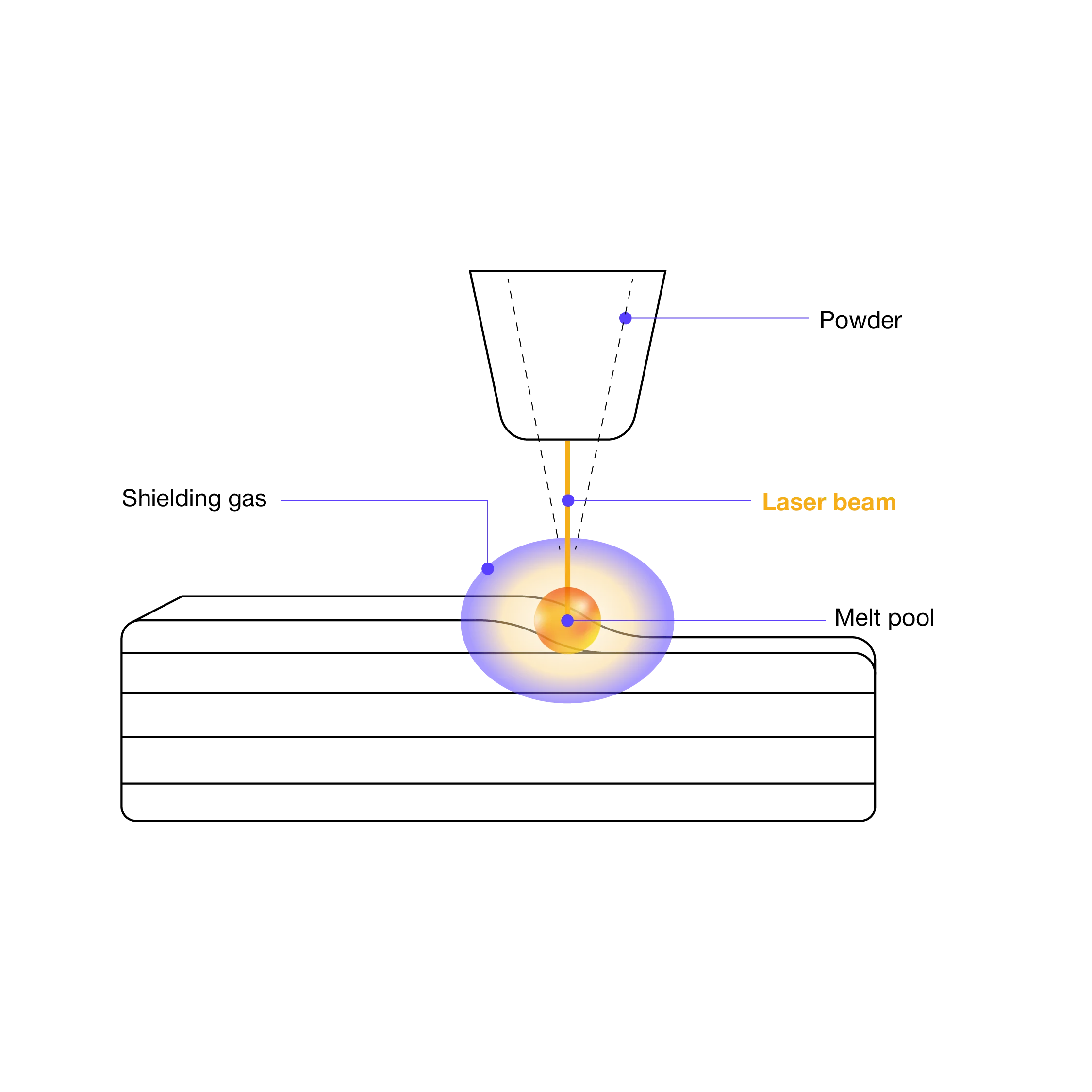

Powder DED technology, recognized as one of the earliest and most versatile AM technologies, is based on feeding raw material directly into the deposition area, where it is immediately melted by a laser and the gradual movement of the deposition head creates individual layers. As the feedstock material is fused, it adheres to the previously deposited layers, creating a cohesive structure.

However, in powder-fed Direct Energy Deposition (DED) systems, powder is continuously directed through nozzles aimed at the focal point of a high-powered laser. The heat from the laser melts the metal powder, forming a molten pool. This molten material is then moved by a motion control system, and the part is constructed layer by layer in free space. The entire process is visible as the part gradually takes shape with each added layer.

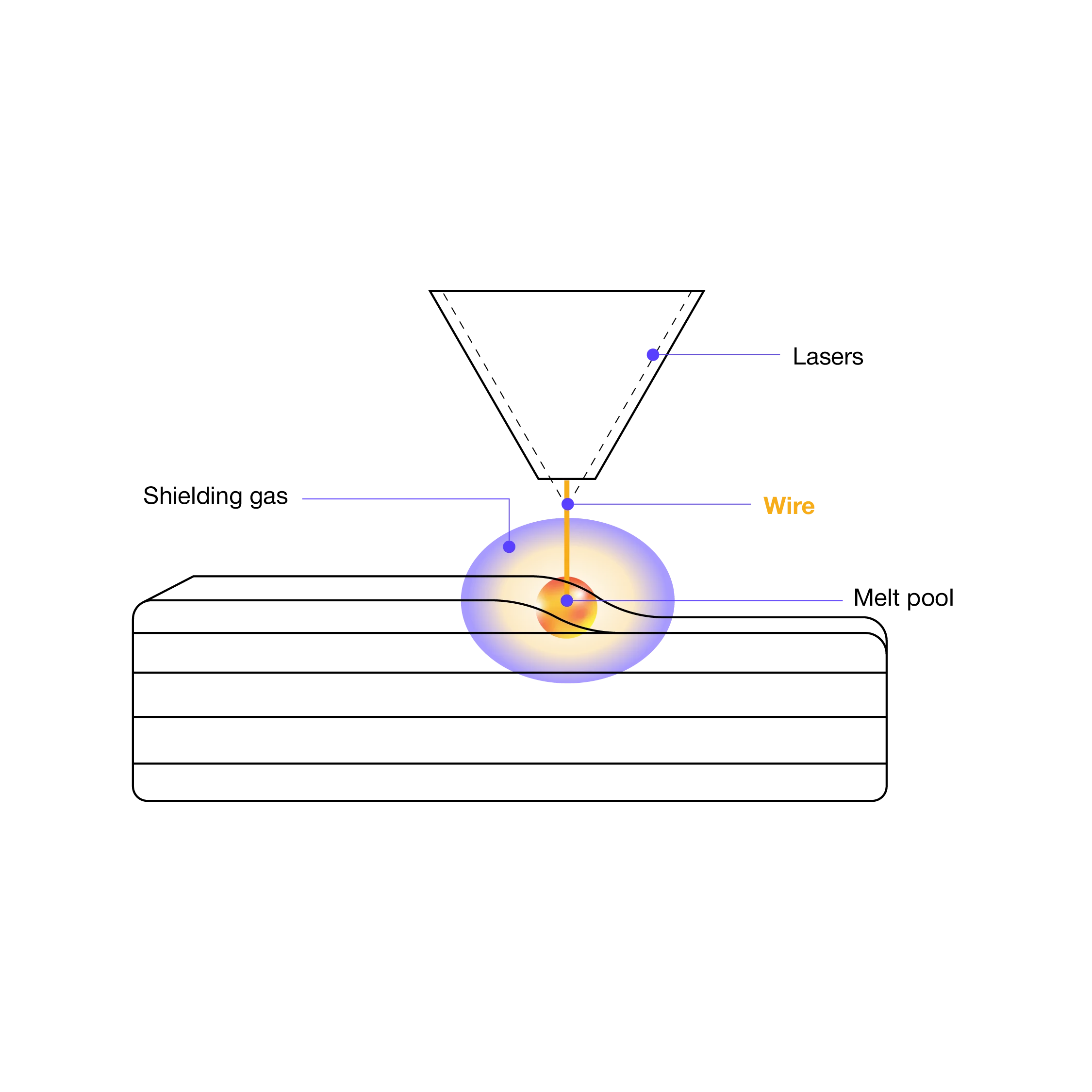

2. Wire + Laser: A new DED combination

Direct Energy Deposition (DED) is a category of Additive Manufacturing (AM) technologies that uses a concentrated heat source to melt and deposit feedstock material.

In metal applications, DED enables the production of large-scale metallic components at significantly higher deposition rates compared to other AM methods like Powder Bed Fusion (PBF). The only powder based DED is Laser Powder-Directed Energy Deposition (LP-DED), which has been extensively employed in cladding over the years.

The combination of using wire as feedstock and a laser as the energy source in DED is considered a new combination in the context of additive manufacturing due to its unique advantages and recent advancements in technology.

While DED itself has been in use for several years, the Meltio’s use of wire feedstock with a laser energy source is a relatively recent development and has gained increasing attention in various industries.

3. Benefits of Meltio’s wire-based 3D printing process

Here are some reasons why this combination is considered new and noteworthy:

1. Continuous deposition:

The continuous feed of wire feedstock during the DED process allows for a seamless and uninterrupted additive build, resulting in increased efficiency and reduced production time. This continuous deposition also eliminates the need for frequent interruptions and manual handling, further streamlining the process.

2. Large-scale applications:

This combination is particularly well-suited for producing large-scale components due to the continuous feed and reduced need for support structures. It allows for the creation of sizable parts with reduced production time and cost-effectiveness.

3. Material waste reduction:

Wire-based additive manufacturing processes often result in lower material waste compared to other methods that use powdered feedstock. Since the wire is consumed only as needed, there is minimal excess material, leading to cost savings and a more sustainable approach.

4. Cost-effectiveness:

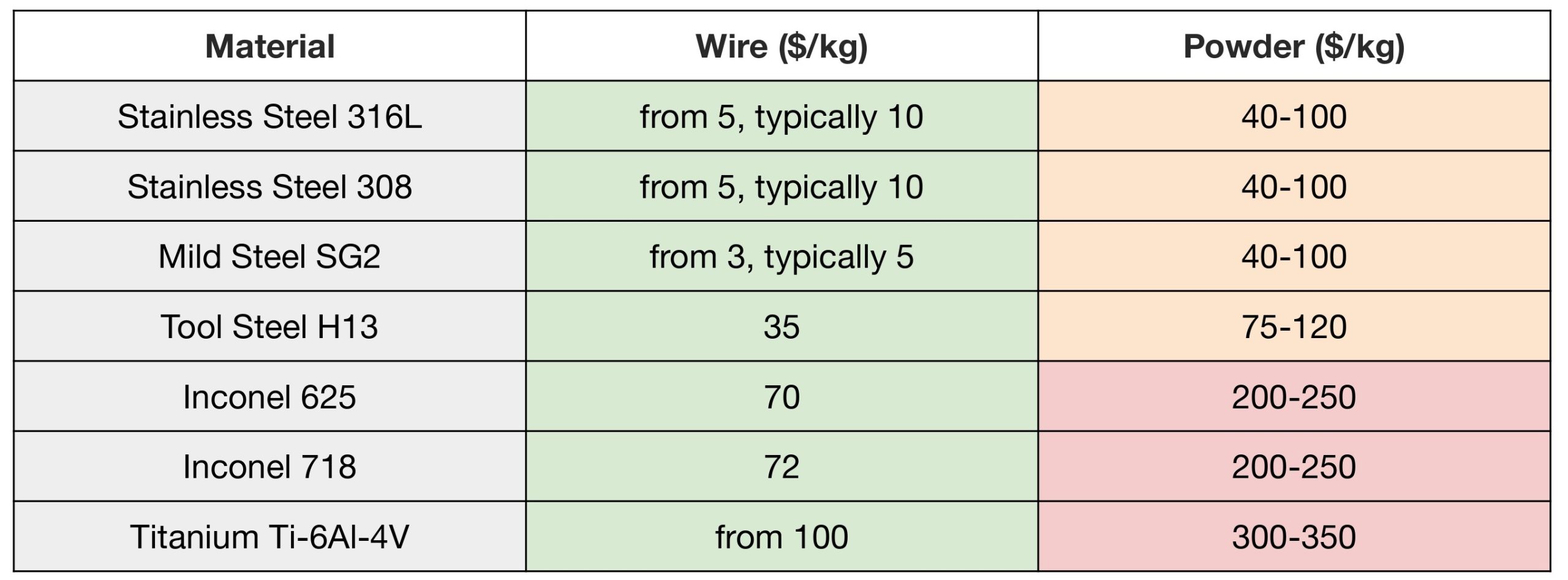

Wire feedstock usually is more cost-effective than powdered alternatives. The production and handling of wire are generally more straightforward and economical, contributing to overall lower material costs. Wire feedstock, readily available as a welding commodity, proves to be significantly more cost-effective than powders. With wire prices starting at approximately $3.00 per pound, compared to the often expensive powders, cost savings of up to 10 times can be achieved. This cost disparity can be particularly pronounced in certain alloys.

5. Enhanced productivity:

It can be more efficient and productive, especially in continuous deposition systems. The continuous feed of wire allows for uninterrupted production, minimizing downtime and maximizing output.

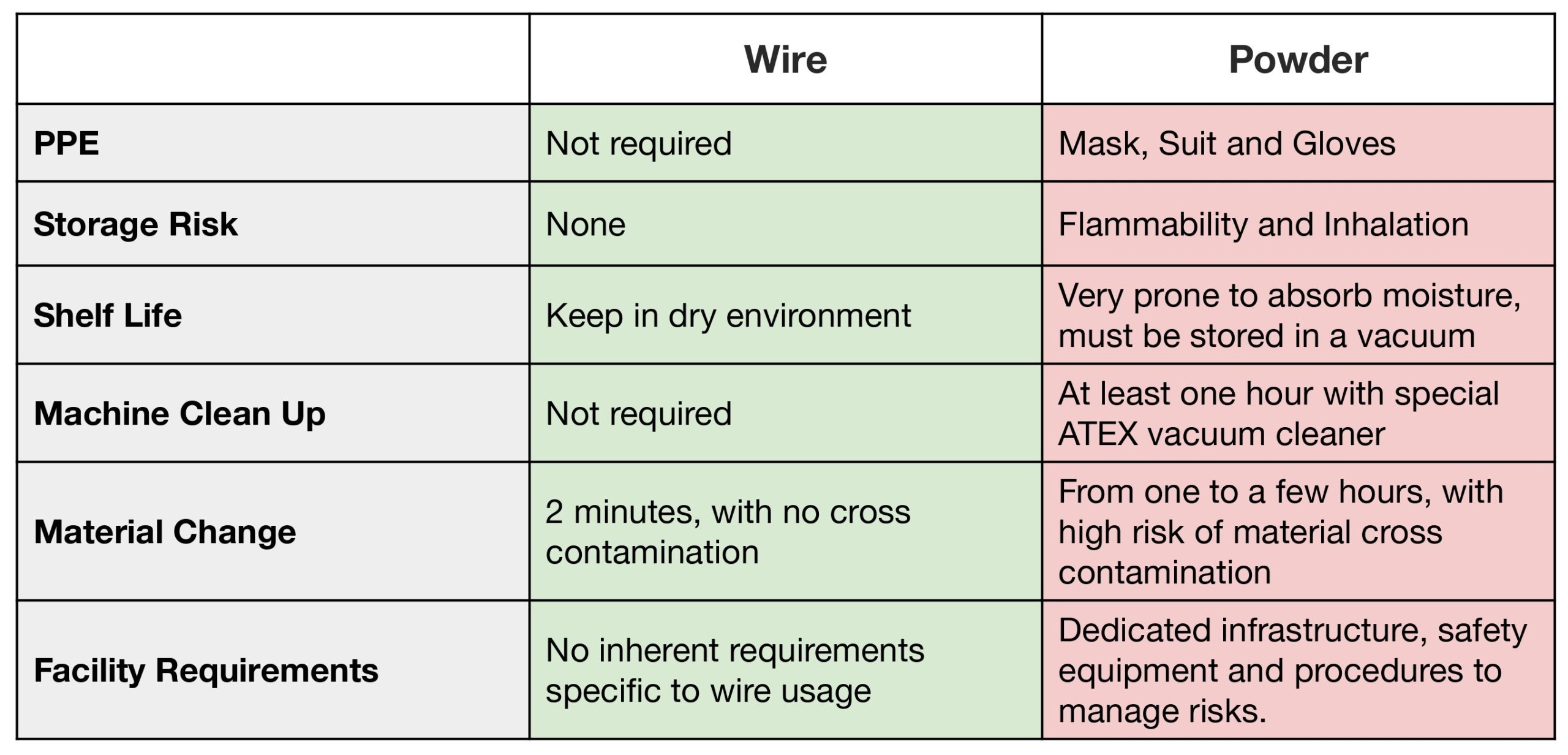

6. Reduced need for protective equipment:

Unlike some powdered additive manufacturing processes, wire-based methods do not involve the risk of aerial particulates. As a result, there may be reduced need for extensive protective equipment, leading to improved operator comfort and safety.

7. Facility requirements:

Wire-based additive manufacturing processes present the advantages of facilities with limited space or specific infrastructure constraints. The simpler handling of wire feedstock requires fewer facility modifications.

8. Convenient storage:

Wire feedstock is easier to store compared to bulkier and more cumbersome powdered materials. Wire feedstock typically requires less storage space allowing a better organization and utilization of storage areas, maximizing the available space.

9. Inventory management:

The structured form of wire feedstock allows for easier inventory management and control. It is simpler to track the quantity of wire remaining, enabling better planning for material restocking. Moreover, wire feedstock tends to have a longer shelf life compared to some powdered materials, which may ensure the material remains usable over extended periods without degradation.

10. Reduced contamination risk:

Since the wire is solid and less prone to dispersal, the risk of cross-contamination between different materials is minimized. In contrast, powdered feedstock can be more susceptible to mixing or accidental spills, leading to potential material contamination. Due to the risk of contamination, this technique follows strict protocols to ensure thorough equipment cleaning after changing the powder. Contamination can negatively impact the microstructure of the parts, potentially compromising their quality and performance.

11. Improved handling and transportation:

Wire feedstock is easier to handle and transport due to its solid and structured nature. Usually, it is commercialized on spools or reels, making it convenient to load into the 3D printing system.

12. Simplified machine clean-up:

Wire-based additive manufacturing processes require less machine clean-up compared to powdered feedstock methods, as there is less residual material to remove after printing. This results in cleaner and tidier workspaces. There is less residue or dust, minimizing the need for frequent cleanups and contributing to a more efficient workflow.

13. Material change:

Switching between different materials is often more straightforward with wire-based additive manufacturing. The ability to swap wire types with relative ease can support the production of diverse components without significant downtime and also allow the printing of dual material parts.

4. Additional advantages of Meltio’s Wire-LMD

14. Zero material waste:

Meltio’s dual wire metal deposition process enables the wire to enter the melt pool coaxially, effectively using 100% of the material. In comparison, powder-based processes often generate significant material waste, ranging from 30% to 50%.

Pipe Manifold by DMZ Engineering

15. Enhanced microstructure:

Meltio’s laser process produces an extremely compact heat-affected zone (HAZ), minimizing heat transfer to the layers below or the surrounding area of the melt pool. This results in a better microstructure of the printed part.

16. Controlled process:

Meltio’s LMD ensures precise control over the wire as it enters the melt pool coaxially. The wire melts at the point of contact with the substrate, independent of the material flow. This allows for the implementation of a sophisticated feedback system, ensuring a stable and controlled process.

17. Meltio’s Deposition Head:

The design features a coaxial wire feed, ensuring that the wire comes through the center of the melt pool. This setup enables consistent printing quality in all directions. This arrangement ensures an extended service life, thanks to the low optical densities of the lasers.

18. Dual Wire capability and multimaterial printing:

Meltio’s printhead is equipped with two independent wire feeders, enabling the printing of two different materials during a single print. This capability allows for applications such as hard-facing or anti-corrosion coatings and it offers an easy, fast, convenient, and sustainable solution for dual 3D printing without the risk of cross-contamination.

Dual material Combustion Chamber: In625 + CuCrZr

Conclusion

In conclusion, PBF, Powder DED, and Meltio offer distinct benefits tailored to different manufacturing needs. PBF (Powder Bed Fusion) is ideal for high-precision, detailed parts, making it perfect for industries like aerospace and healthcare. However, its slower processing speed and higher costs can limit larger-scale applications. On the other hand, Powder DED (Powder Directed Energy Deposition) offers faster printing and material versatility, making it suitable for large parts and repairs, but it sacrifices resolution and surface quality compared to PBF.

Meltio technology stands out with its ability to use multiple materials in a single print, offering great flexibility in hybrid manufacturing. The right choice of technology depends on the specific requirements of the project, such as material needs, part size, resolution, and cost, ensuring optimal results in additive manufacturing.