Mild steel, also known as low-carbon steel, is one of the most widely used metals in the world thanks to its balance of affordability, machinability, and versatility. At Meltio, we work extensively with mild steels such as ER70S-6, which not only provide excellent weldability and ductility but also serve as an ideal entry point for companies starting their journey with metal additive manufacturing.

Beyond its standalone benefits, mild steel plays a crucial role in hybrid and dual-material applications, offering significant cost and time savings without compromising on performance.

1. Material overview

Mild steels are low-carbon steels that make up one of the most common groups of metals worldwide. Less carbon means that mild steel is typically more ductile, machinable, and weldable than high carbon and other steels. However, it also means it is nearly impossible to harden and strengthen through heating and quenching.

Thanks to its predominantly ferritic microstructure, it exhibits strong magnetic properties. As a curiosity, in the applications department we often use a magnet when we are not sure what type of steel a part is made of, as near net shaped steel parts look really similar among our Meltio materials.

They are well represented by ER-series wires, widely used in welding, as well as by other structural steels with comparable properties. These materials are particularly attractive for additive manufacturing in terms of cost and compatibility. Moreover, we have also tested other grades such as ER80, ER100, ER110 with satisfactory results.

The grade we supply as standard is ER70S-6. It offers consistent print quality and is readily available on the market. However, it also presents some limitations: its deposition rates are lower than those of stainless steels like 316L, resulting in longer build times for large-scale parts, but keeping material costs low.

2. ER70S-6

This material finds applications across many sectors such as construction, automotive, and general manufacturing. Our most common request from the market side is to use a dual-material configuration in parts which are meant to have a cost-effective solution. In addition, mild steel is commonly used for rafts because it can be easily removed from the build plate.

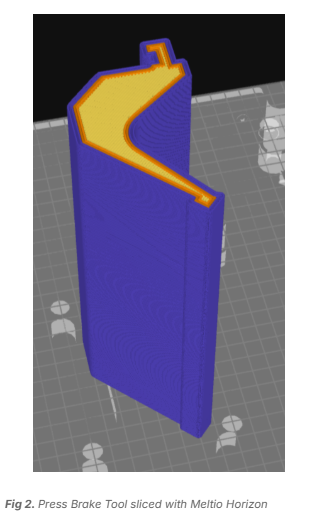

The following picture depicts a Press Brake tool, core of most metal sheet forming operations. These tools are manufactured in a variety of sizes and shapes and they are adopted in a wide range of industries. In this case, an ER70S-6 core was adopted with the rest of the part being printed with a 3 mm Tool Steel H11 shell.

The outer zone of the press brake tool is made from H11 because that is the area exposed to high wear, pressure, and thermal cycling during sheet forming. These working surfaces need the hardness and durability of a tool steel. The inner core, however, does not experience the same stresses. Therefore, this core reduces cost and printing time without compromising performance, since the critical properties are provided by the H11 on the outside.

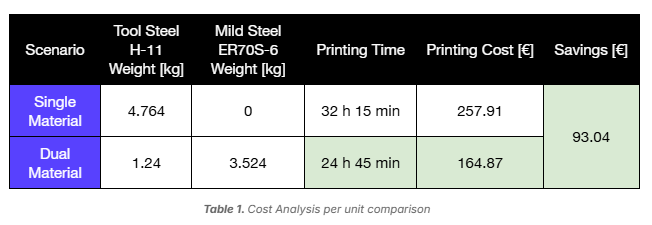

The following table compares the cost of manufacturing a full H11 part versus the Meltio dual-material solution, both printed in a M600.

Thanks to this dual-material approach, the use of tool steel is reduced by almost 74%, while the overall printing cost per part drops by more than 36%. Build time is also reduced by around 23%, since the deposition rate of H11 is significantly lower than that of mild steel. This shift not only cuts down on the reliance on costly alloys but also increases both the cost and time efficiency of the entire process. In a real production environment, achieving savings of this magnitude would mark a turning point.

In terms of productivity, ER70S-6 deposition rates can go up to 423 g/h with the 1.4 kW Blue Laser. This makes it especially attractive for large-format parts, quick-turnaround prototypes, and economical repairs, as the one mentioned above.

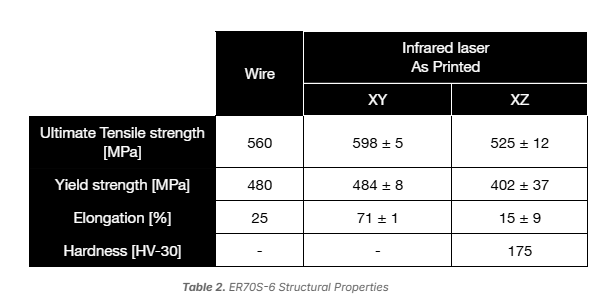

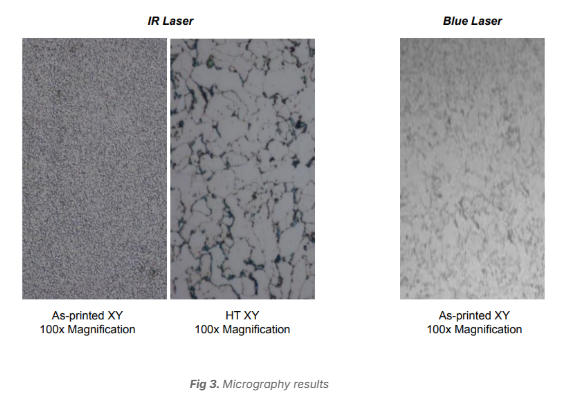

The micrography results were obtained by an external laboratory from a 10x10x60 mmsample extracted from a printed block, following ASTM standards and ensuring proper preparation and examination of the microstructure.

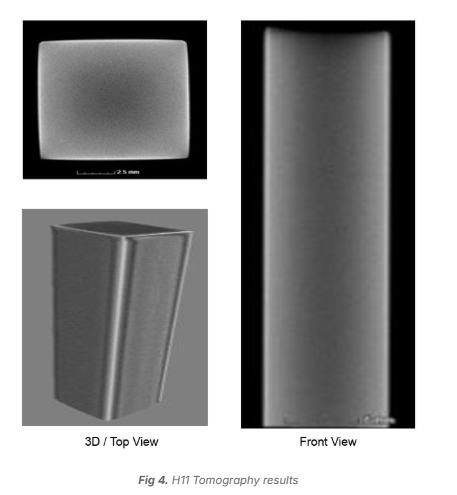

On the other hand, regarding tomography tests, the results of the CT scan of a sample using an infrared laser are attached, showing no detectable voids or defects, with a resolution of 24 μm per pixel.

Beyond stand-alone use, it is frequently employed in hybrid manufacturing strategies, serving as a structural base on which more advanced alloys can be added in critical zones. This versatility explains its popularity as a practical entry point for companies adopting metal 3D printing with Meltio.

3. Why choose Meltio’s Mild Steel

Reduce material expenses significantly by combining mild steel cores with high-performance alloys only where needed.

High deposition rates

Achieve faster builds and quicker turnarounds, especially for large-format parts.

Versatility

Suitable for standalone parts, dual-material strategies, and as a structural base for more advanced alloys.

Reliability

Proven mechanical properties and consistent print quality ensure dependable results across projects.

Meltio’s ER70S-6 mild steel offers manufacturers a balance between affordability and performance, making it an ideal choice for additive manufacturing and hybrid applications.

TIP: Know more about compatible and Meltio materials by downloading the Meltio Materials Printable List.

4. Main applications for Mild Steel

- Construction

Structural components, repair parts, and prototypes.

- Automotive

Cost-effective tooling, fixtures, and functional prototypes.

- General manufacturing

Press brake tools, machine components, and hybrid builds.

- Education and research

Entry-level material for training, experimentation, and adoption of metal 3D printing.

The W-LMD technology produces parts with exceptional microstructure and a density of 99.998%, surpassing the properties of castings and rivaling those of forgings.

5. A cost-effective high-performance solution

Mild steel, and particularly ER70S-6, demonstrates how cost-effective materials can deliver high-performance results when combined with the right additive manufacturing strategy. From reducing reliance on expensive tool steels to enabling faster production cycles, it offers manufacturers a smart balance between efficiency and durability.

As a result, mild steel continues to be a cornerstone in Meltio’s material portfolio, empowering industries to adopt 3D printing at scale with confidence and practicality.