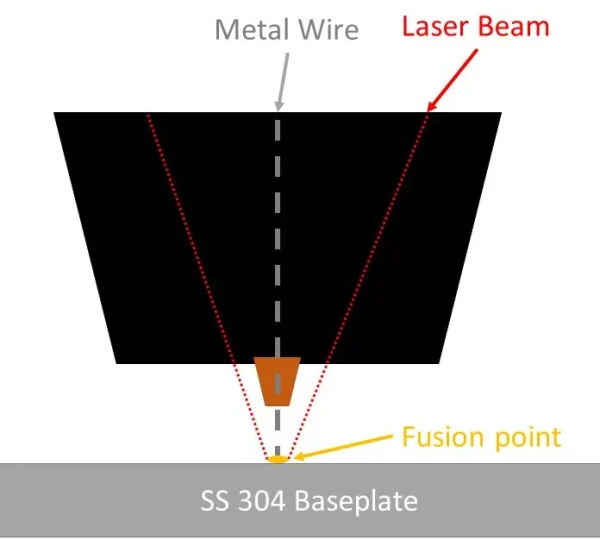

As additive manufacturing continues reshaping how industries build and repair parts, wire-based Directed Energy Deposition (DED) technologies like Laser-Wire Metal Deposition (L-WMD) are gaining attention.

These methods promise to improve material efficiency, reduce lead times, and enable localized reinforcement or repairs of metallic components. This blog dives into how LWMD impacts ER70S-6 steel, a commonly used structural material, and what that means for industries that rely on durable, cost-effective metal parts.

This blogspot is a summary version of the article “Influence of Laser-Wire Metal Deposition Process Parameters on the Mechanical Properties and Microstructure of ER70S-6 Steel” developed by Daniel Gomez-Lendinez, Jesus Garcia-Moreno-Caraballo, Sergio Corbera and Rafael Barea (Escuela Politécnica Superior, Universidad Nebrija).

1. The challenge of quality control

ER70S-6 is a widely used carbon steel with good weldability, commonly applied in general construction, shipbuilding, and automotive manufacturing. However, in additive manufacturing, especially with DED methods like LWMD, controlling the mechanical properties and microstructure of the final part remains a challenge.

Key issues include porosity, inconsistent grain structure, and mechanical weaknesses that arise due to improper process parameter settings (laser power, wire feed rate, scanning speed).

The W-LMD technology produces parts with exceptional microstructure and a density of 99.998%, surpassing the properties of castings and rivaling those of forgings.

Researchers explored how adjusting LWMD parameters influences the final quality of ER70S-6 steel deposits. Their goal: to find a combination of settings that maximize material performance, especially in terms of tensile strength, hardness, and structural integrity.

2. Elevating ER70S-6 performance

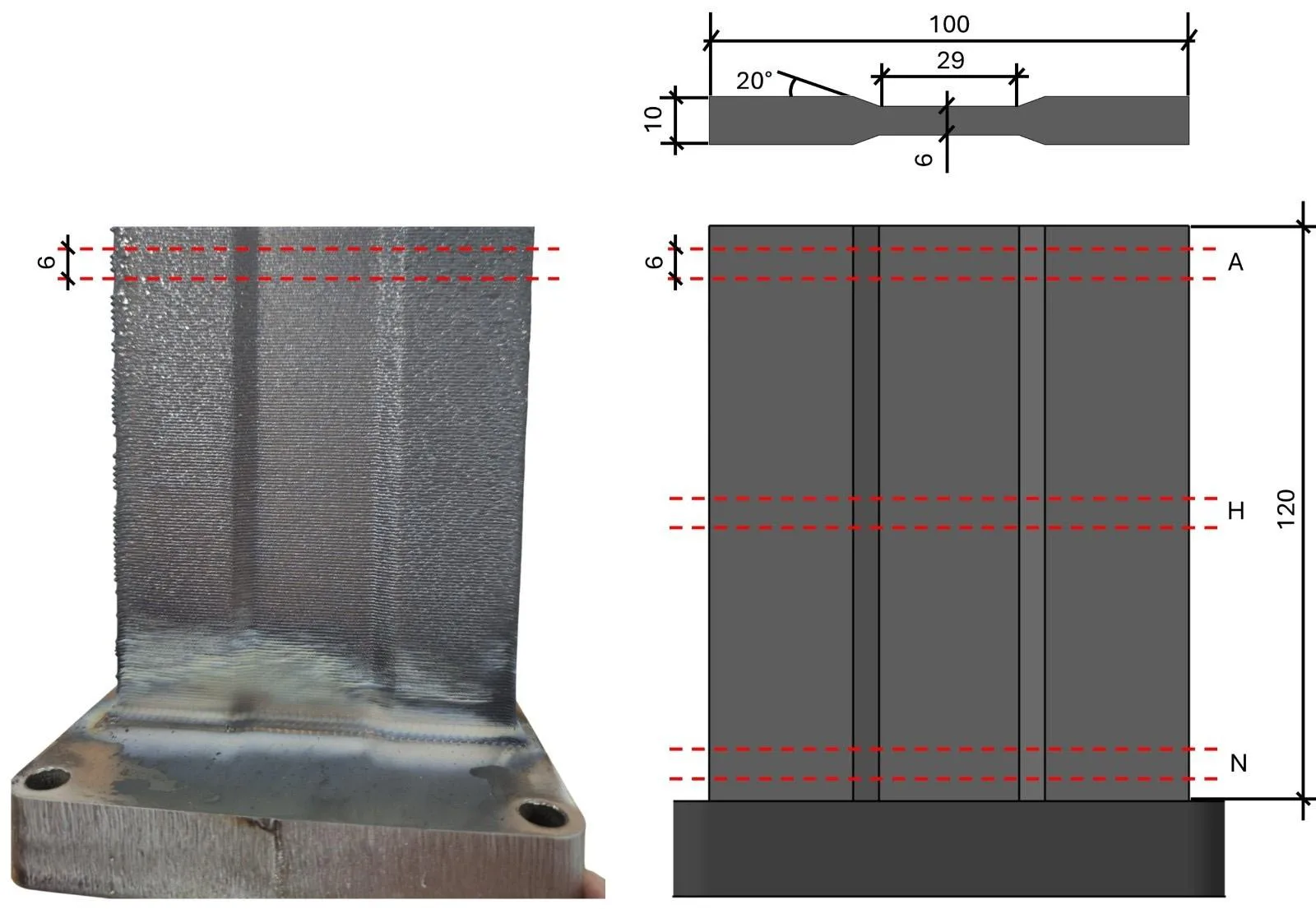

To tackle these issues, a team of researchers designed a study to systematically examine how different LWMD process parameters affect the quality of ER70S-6 steel builds. They created multiple wall-shaped test parts by varying three main inputs: laser power, wire feed rate, and scanning speed.

The researchers then evaluated each printed sample’s mechanical performance (like tensile strength and hardness) and microstructure (grain size, uniformity, defects) to determine which settings delivered the best results.

Their controlled setup and rigorous analysis helped identify how to optimize the process to get stronger, more reliable parts with fewer internal flaws.

Setup and technical details:

-

Material: ER70S-6 steel wire

-

Deposition method: Laser-Wire Metal Deposition

-

Part type: Wall structures made by stacking single-layer beads

-

Part size: Approximately 90 mm long × 10 mm wide × 30 mm tall

Parameters studied:

-

Laser power: 1000 to 1500 W

-

Wire feed rate: 1.5 to 3.0 m/min

-

Scanning speed: 6 to 12 mm/s

Each combination influenced the final outcome in terms of bonding, surface quality, internal structure, and performance.

TIP: Know more about compatible and Meltio materials by downloading the Meltio Materials Printable List.

3. Key findings

- Fine-Tuned Microstructure: The best samples had a refined, consistent grain structure and fewer defects.

- Higher Mechanical Performance:

- Tensile Strength: Up to 556 MPa

- Hardness: Between 190–210 HV

- Quality Control: Avoided porosity and cracking through optimal parameter tuning.

4. Benefits of Meltio’s LWMD for ER70S-6

Material efficiency

Uses only the necessary amount of metal, saving costs and time.

Versatility

Can be used for both new part builds and repairs.

Performance by design

Fine-tuning parameters allows parts to be engineered for specific loads or stresses.

5. Application sectors

With improved properties, parts printed in ER70S-6 using LWMD are well suited for, among others:

- Automotive: Custom mounts, brackets, tooling, and prototypes.

- Construction: Structural connections and support parts.

- Shipbuilding & Offshore: Pipe fittings and structural reinforcements.

- Heavy Equipment: Wear parts and repair components for machinery.

Multi-metal Topologically Optimised beam with Meltio Technology printed for MMTO

Conclusion

This research shows that Laser-Wire Metal Deposition can be a game-changer for producing and repairing steel components—especially when using materials like ER70S-6. With the right process parameters, manufacturers can unlock a new level of efficiency, customization, and performance for demanding applications across multiple industries.