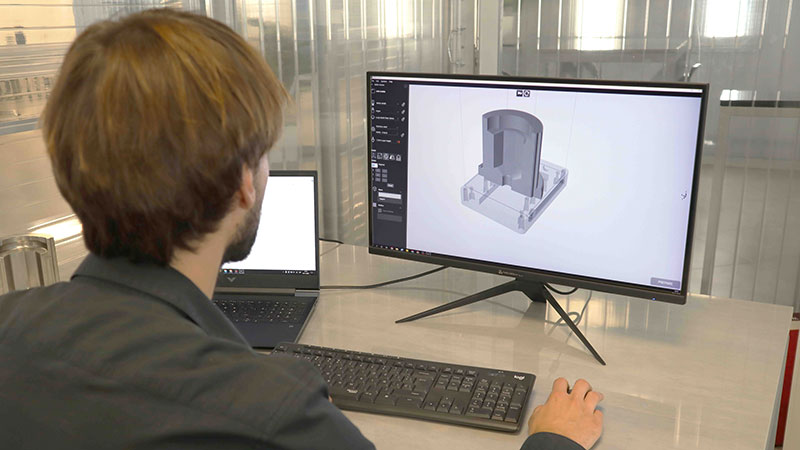

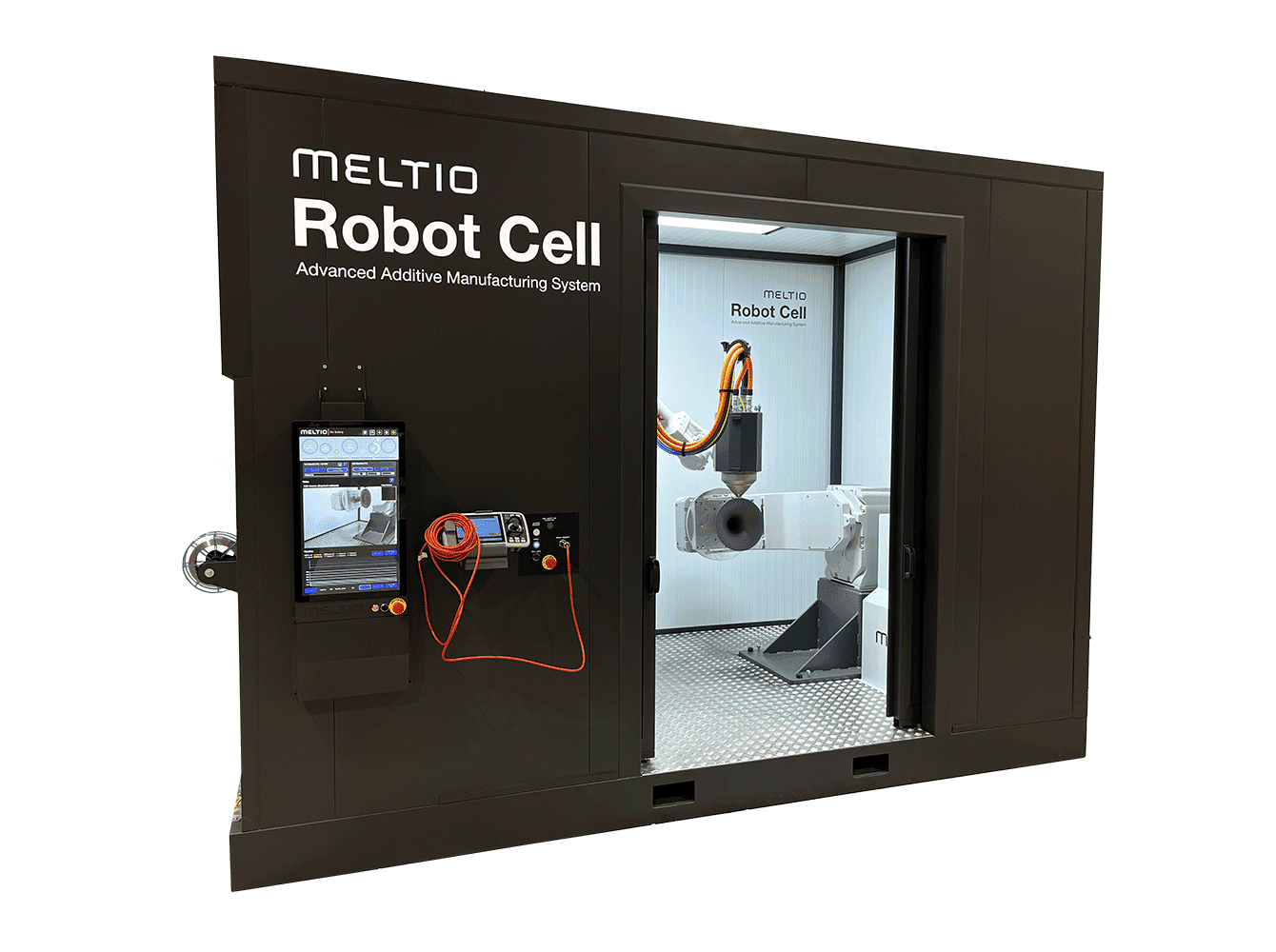

Meltio Robot Cell

Turn-key large format AM

Deploy a certified robotic 3D printing factory

A powerful 8-axis platform for creating complex geometries and large-scale components with unprecedented freedom and precision.

Factory-ready deployment

Allows the customer to receive a ready to use cell for robotic metal 3D printing.

Tier-1 industrial hardware

Built with best-in-class robotic arms and laser-safe enclosure standards.

CE Certified & Class 1 safety

Fully enclosed operation with interlocks and active laser windows. Compliant with strict EU/US safety regulations.

Focus on printing

On-site training for enabling the end user to be successful with Meltio and develop applications in short time.

Technical specifications

| CLASS 1 Laser Product. | |

| Meltio Space 1 (one) year subscription. | |

|

Large 3D Printing Volume with Continuous positioner axes interpolation. |

|

|

All equipment and peripherals anchored on the platform. |

|

|

Standard CE certification. |

|

|

Steel platform with leveling points and wiring ducts. |

| All cell controls unified on single control panel. | |

| Everything is sent integrated and tested. | |

| The final reseller/integrator focuses work on training and enabling the client to manufacture parts. | |

| Load and unload from truck with regular size and load forklift. | |

| Includes 300x400mm actively cooled build platform and buildplates. |

| Power Input: | Three phase 400V 50Hz 5 poles (3W+N+PE) Protection up to 50A 20kw peak power consumption Average power consumption at 15-18 A: -> 7kw |

|---|---|

| Alternative Power Input Upon Request: | Three phase 440V 60Hz 5 poles (3W + N + PE) Three phase 230V 60Hz 3 poles (3W) |

| Carbon Steels: | High impact strength, retain hardness at high temperatures |

| General dimensions: |

Ducts for wiring and integration elements, allowing a clean floor. 4.050 x 2.350 x 3.000 mm |

|---|---|

| Structural support: | Laser safe enclosure according to IEC 60825-1 and IEC 60825-4. |

| Leveling points: | Robot Cell product as Class 1, reducing the risks for the user. |

| Oxidation resistance: |

Highly fire-resistant enclosure materials that do not produce toxic particles. Specifically: B-s2,d0 according to UNE EN 13501-1 |

Single three-phase connector input. | Safe environment for the end customer. |

All cell controls unified on single control panel: | European CE and laser safety regulations. UCKA in UK and UL in America to be evaluated. |

| Connected to the customer’s local network (LAN) for PC interconnectivity. | Laser safe enclosure according to IEC 60825-1 and IEC 60825-4. |

| ABB’s SafeMove to avoid collisions with enclosure. | Fully Tested. |

| Specific Quality Controls before and after integration, ensuring maximum performance at its final destination. |

| Meltio Engine Control Unit. |

| Engine and Build Platform Water Chillers. |

| External Feeders, for spool holders and drums of +100kg |

| Inert Gas Supply options: – Attachments for three 50L Argon bottles with non-return valves. – Optional Meltio Gas Regulator – Or Supplied by customer |

* All these equipment and peripherals are anchored on this platform and may not exceed from the maximum dimensions of the self-supporting platform during transport.

| Load: | 500 kg max load (Standard) |

|---|---|

| Positioner Interpolation: | ⌀ 1000 mm x 1200 mm |

| No Positioner Interpolation: | 2000 x 1000 x 1000 mm Custom build platform not included No positioner movement, only robot tool orientation |

| Actively Cooled Build Platform: | Buildplate 300x400mm Buildplate 150x200mm Buildplate 120x100mm |

* The cooling bed allows control of the temperature of the prints as wells to protect the positioner, hardware that cannot be over 70ºC on periods of more than 24h.

| Updated and renewed User Interface. |

| Timeline for Sensors Analysis. |

| Custom profiles without the need of writing macros, every possibility parametrized. |

| Live 3D model based on reading TCP positions from robot. |

| HD Webcam. |

| Profiles for Meltio Materials and Meltio Space. |

| Compatible with Welding Camera. |

Meltio Engine Blue Integration kit

| Laser System: | Blue Laser (Higher absorption and power efficiency; wider range of compatible materials than IR) 1000W 9 x 450 nm direct diode lasers |

|---|---|

| Printhead: | Robot Mounted 20.5 to 23 kg |

| Printhead Size (WxDxH): | 262 x 272 x 572 mm |

| Control Unit: | Wall mounted, air-cooled 80.5 kg 600 x 300 x 800 mm. Separate wall mounted 27″ HMI |

| Cooling: | Water-cooled deposition head. Chiller lncluded |

| Print Envelope (WxDxH): | Depending on robot’s reach |

| Process Control: | Melt Pool Camera & Closed-loop wire modulation |

| Power Input: | 200/240 V 3W+PE 380/415 V 3W+N+PE |

|---|---|

| Power Consumption: | 9,2 kW peak 2-5 kw avg. |

| Slicer Software: | Meltio Space 1-year subscription lncluded |

|---|---|

| Feeder System: | Quad-point traction servomotor feeder, frictionless liners |

| Wire Feedstock: | Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready |

| Product Configurations: | Single or Dual Wire |

| Compatible Materials: | Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium, Copper Alloys, Gold alloys and more |

Meltio Engine IR Integration kit

| Laser System: | Infrarred Laser 1200W 6 x 976 nm direct diode lasers + fibers & colimators |

|---|---|

| Printhead: | 15.5 kg |

| Printhead Size (WxDxH): | 230 x 310 x 710 mm |

| Control Unit: | Floor Mounted (Wheeled) 125 kg with 27″ HMI 390 x 650 x 1600 (deployed screen) |

| Cooling: | Water-cooled control unit and deposition head. Chiller included |

| Print Envelope (WxDxH): | Depending on robot’s reach |

| Process Control: | Closed-loop, wire modulation |

| Power Input: | 200/240 V 3W+PE 380/415 V 3W+N+PE |

|---|---|

| Power Consumption: | 2 – 5 kW peak depending on selected options |

| Slicer Software: | Meltio Space 1-year subscription lncluded |

|---|---|

| Feeder System: | Dual traction stepper motors + External Feeder (Push-pull system), conventional wire liners |

| Wire Feedstock: |

Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready |

| Product Configurations: | Single or Dual Wire |

| Compatible Materials: | Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium and more |

Success stories

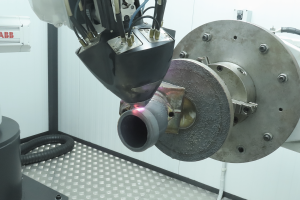

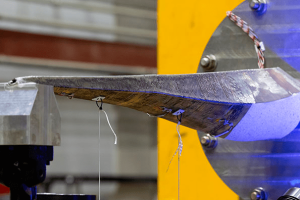

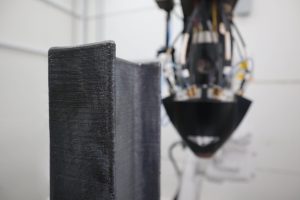

Meltio Robot Cell applications

The best efficiency in cost without losing mechanical properties

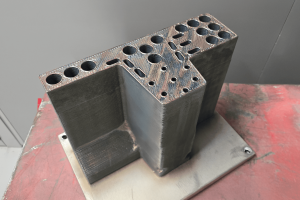

Construction

| Size: | 250 x 765 x 45 mm |

|---|---|

|

Material: |

NicarbW |

|

Weight: |

0.6 kg |

|

Print time: |

3h 15′ |

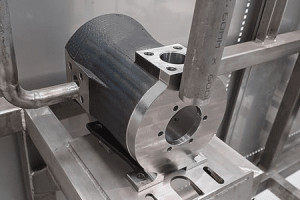

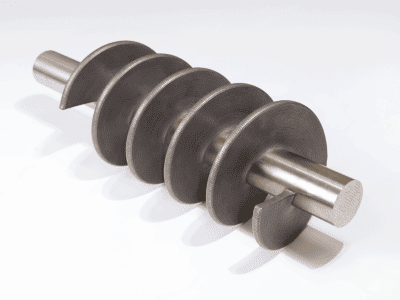

Food Industry

| Size: | 150 x 150 x 330 mm |

|---|---|

|

Material: |

Stainless Steel 316L |

|

Weight: |

4.6 kg |

|

Print time: |

16h 45′ |

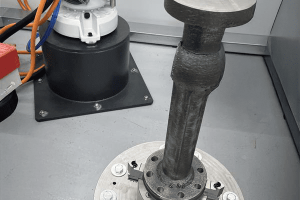

Mining

| Size: | 75 x 75 x 230 mm cladded |

|---|---|

|

Material: |

Stainless Steel 316L |

|

Weight: |

6.6 kg |

|

Print time: |

21h 16′ |

Food Industry

| Size: | 130 x 903 x 855 mm |

|---|---|

|

Material: |

Stainless Steel 316L |

|

Weight: |

5 kg |

|

Print time: |

28h 15′ |

Do you want to know more about printed part properties?

Customer validation & Success stories

We are using the Meltio Robot Cell to repair high-value mining equipment. By cladding wear-resistant layers onto worn shafts and crushers, we extend the life of heavy machinery by 300% compared to buying new parts.

Integration was seamless. We mounted the Meltio head onto our existing ABB robot arm, transforming a standard handling bot into a flexible metal manufacturing cell without altering our factory floor layout.

We wanted a solution that would allow us to produce large, custom parts internally — without the overhead of tooling, molds, or external delays. Meltio’s technology, combined with robotic freedom, gave us exactly that.

We’ve opened a really unique design space through 3D printing. This project has demonstrated that additive manufacturing has the potential to produce very strong, stiff structures that will be good for marine energy.

Know more about Meltio Robot Cell

Meltio Design Guidelines

Watch this webinar to explore the rules for parts manufactured with Meltio's technology.

Get a quote Meltio Robot Cell

Receive a tailor-made offer

Know more about us

Check our latest news and use cases