Technological platforms

for production processes

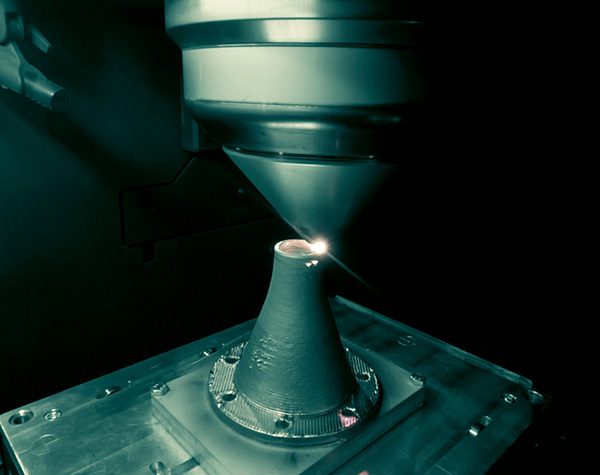

Advanced additive manufacturing for metal alloys

Industrialize your production

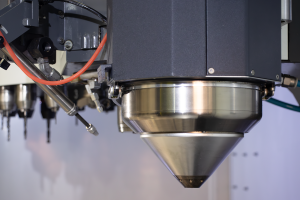

with Wire-Laser Metal Deposition (LMD)

High density, low cost, and open materials

Competitive advantages of Meltio LMD

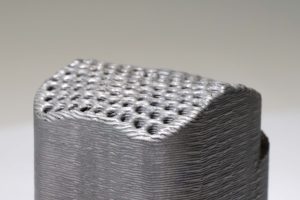

Dual-wire in-process alloying

Print dual wire for hard-facing or anti-corrosion applications to create new alloys on the fly.

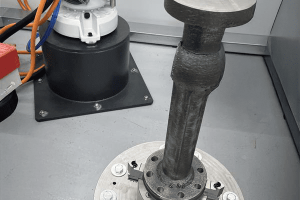

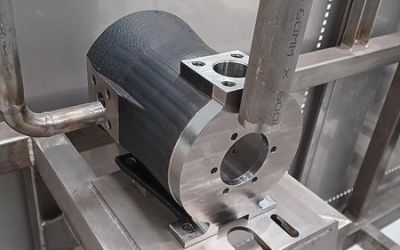

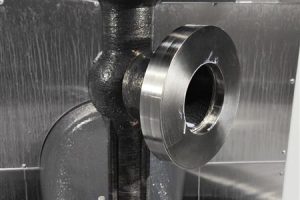

Forging-level part density

Meltio LMD process can produce fully dense parts, achieving the best mechanical properties.

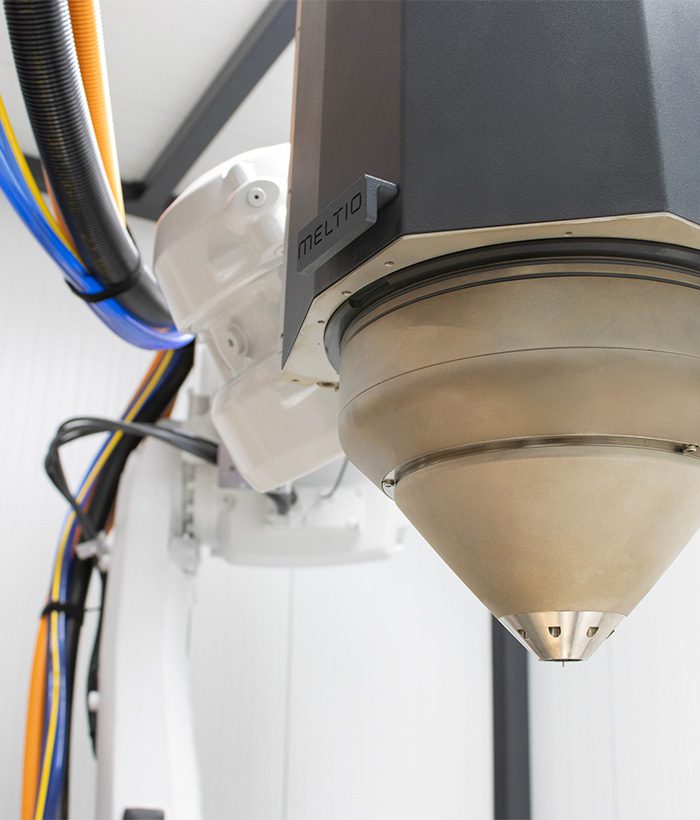

100% material efficiency

Meltio’s multi-laser metal deposition process allows the wire to enter the molten pool coaxially, having 0 % material waste.

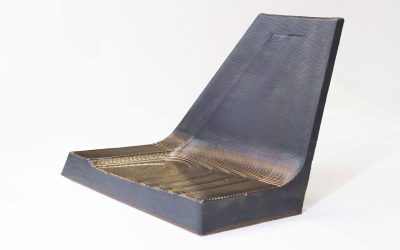

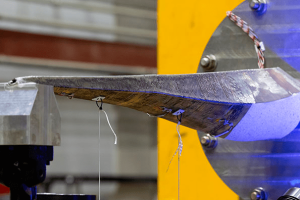

Near-net shape

Our technology produces high-resolution near-net shape parts. Thanks to this and part repairs, we can reduce material usage by up to 90 %.

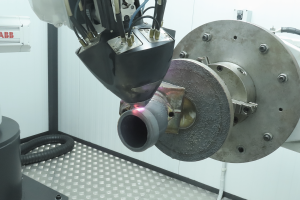

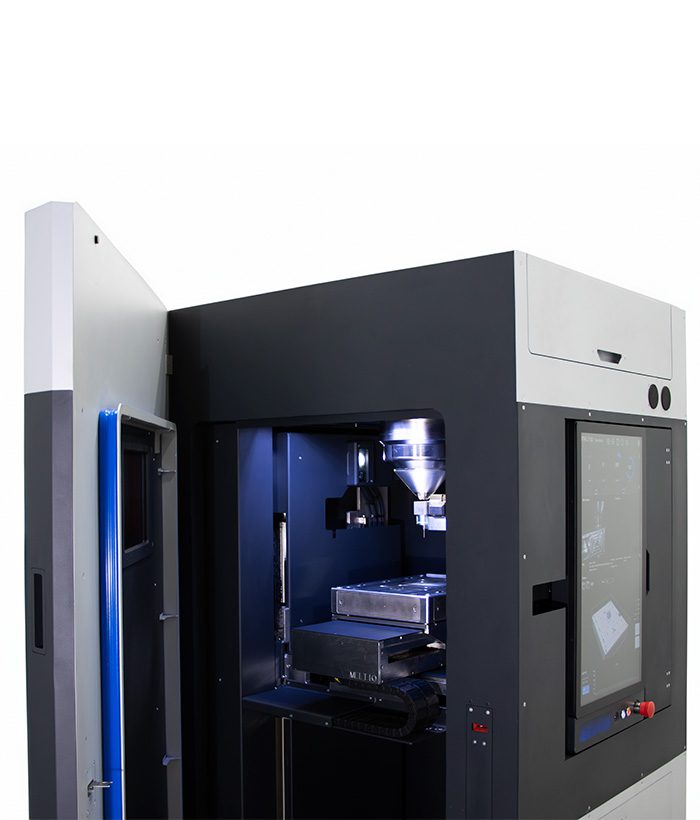

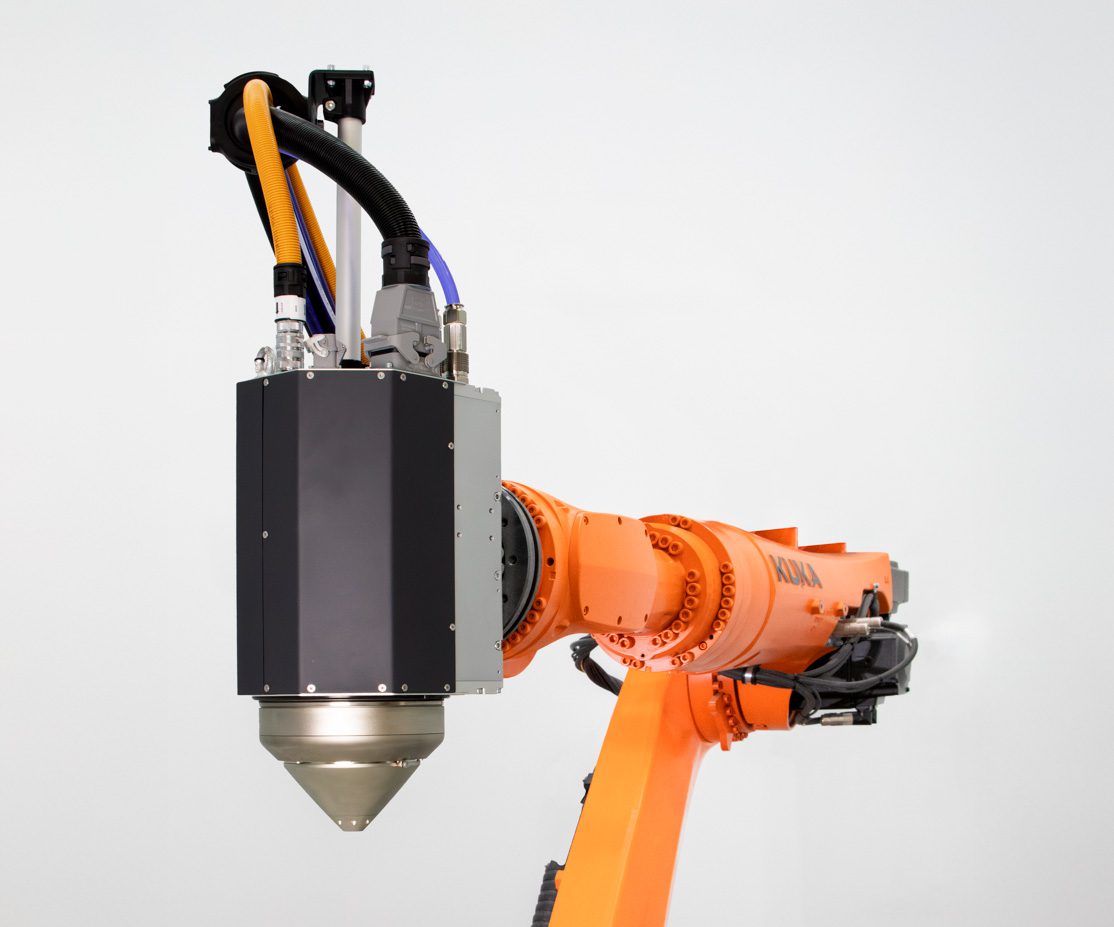

Select your production platform

Powered by Meltio

Already validated solutions for your sector or region by our Certified Integration Partners.

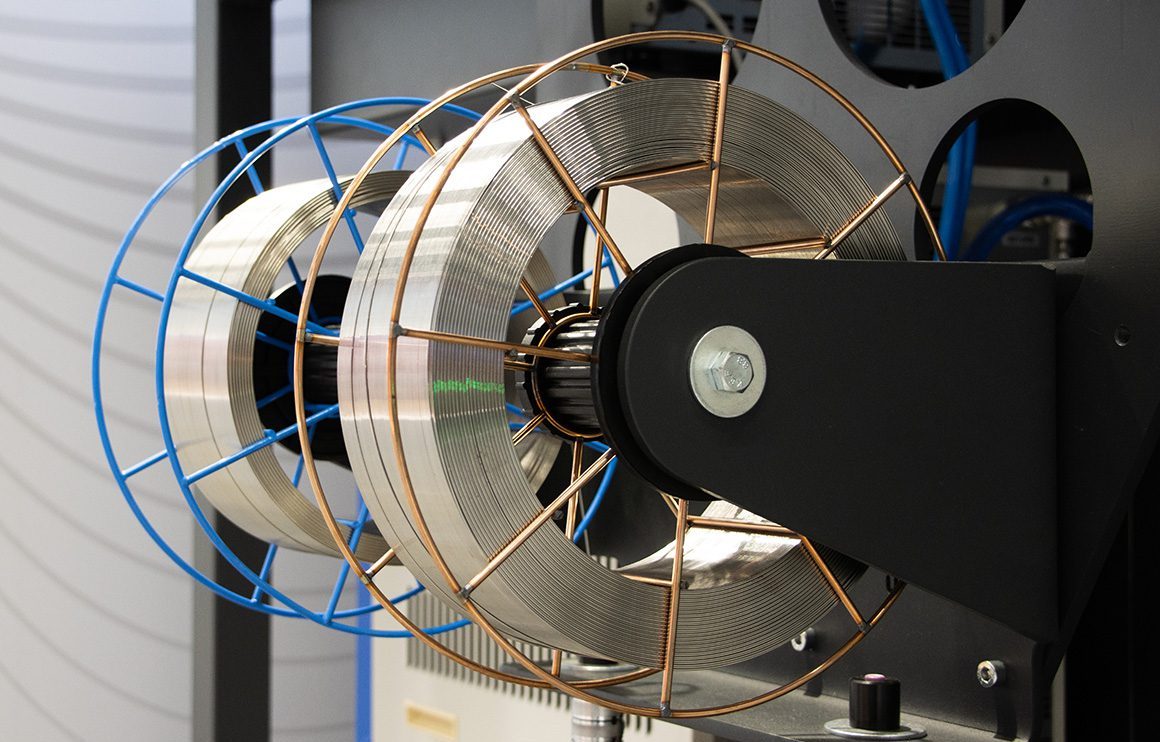

Open material ecosystem: Commodity welding wire

Meltio’s technology ensures

reliable, high-density parts with validated structural integrity.

Customer validation & Success stories

We tested multiple AM technologies, but Meltio’s wire-laser process was the only one that offered the density and mechanical properties of forged steel at a cost competitive enough for industrial tooling applications.

For the construction industry, downtime is the enemy. The Meltio system allows us to manufacture stainless steel replacement parts on-demand using standard wire, decoupling our maintenance schedule from global supply chain delays.

The other systems that we looked at required processing of the 3D print, which was costly to get your finished print.

The ability to 3D print stainless steel directly onboard a naval vessel allows us to maintain operational readiness at sea. Meltio’s use of standard welding wire solves the logistics problem—we don't need to carry hazardous powders, just spools of wire.

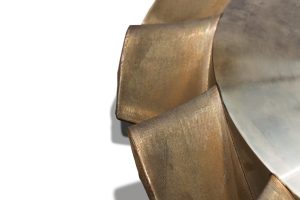

The Hybrid manufacturing capability is revolutionary for our pump impellers. We print the rough geometry and immediately machine it to final tolerance in the same setup. It reduced our lead time from 8 weeks (casting) to just 3 days.

We wanted a solution that would allow us to produce large, custom parts internally — without the overhead of tooling, molds, or external delays. Meltio’s technology, combined with robotic freedom, gave us exactly that.

We’ve opened a really unique design space through 3D printing. This project has demonstrated that additive manufacturing has the potential to produce very strong, stiff structures that will be good for marine energy.

Find your application or sector

Validated industrial applications

Discover the applications developed by Meltio and their impact across various industries.

Know more about us

Check our latest news and use cases

Do you need help?

Reach out! We’d love to hear about your project.