Meltio Engine CNC Integration

Hybrid Additive Manufacturing

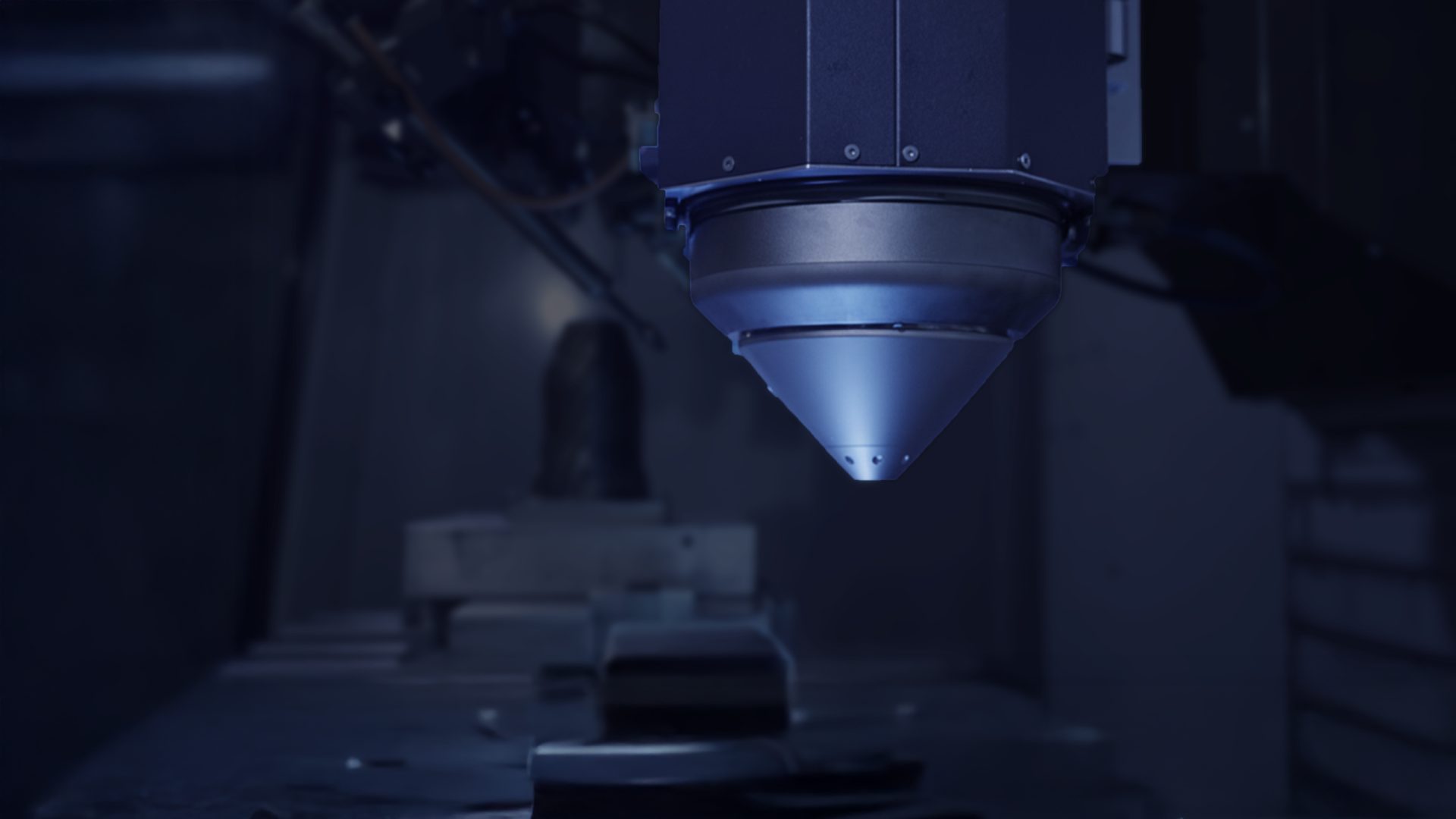

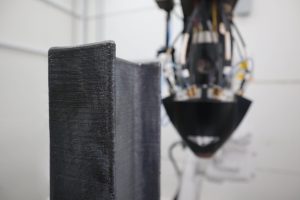

Turn any VMC into a metal 3D printer

The most affordable hybrid manufacturing solution, fitting almost any Vertical Machining Center in the market. Enable metal 3D printing and machining of complex geometries in a single process step.

The Meltio Engine Integration kit is the ideal complement for near-net shape manufacturing, repair and feature addition.

Hybrid manufacturing

Create highly complex parts with machining tolerances in the same process.

Geometry freedom

No inherent constraints when the working envelope is only limited by the size of the motion system.

Retrofitting

Provide new capability to any CNC machine by turning it into an hybrid metal manufacturing system.

Part repair

Cost-effective component repair, part augmentation, and feature addition.

Technical specifications

Meltio Engine Blue Integration kit

| Laser System: | Blue Laser (Higher absorption and power efficiency; wider range of compatible materials than IR) 1000W 9 x 450 nm direct diode lasers |

|---|---|

| Printhead: | Mounted on the right side of the spindle 32.5 to 35 kg |

| Printhead Retracted Size (WxDxH): | 280 x 332 x 684 mm |

| Printhead Unretracted Size (WxDxH): | 280 x 332 x 943 mm |

| Control Unit: | Mounted on machining center, air-cooled 80.5 kg 600 x 300 x 800 mm. 17″ HMI screen placed beside CNC controller |

| Cooling: | Water-cooled deposition head. Chiller lncluded |

| Print Envelope (WxDxH): | Depending on the machining center |

| Process Control: | Melt Pool Camera & Closed-loop wire modulation |

| Power Input: | 200/240 V 3W+PE 380/415 V 3W+N+PE |

|---|---|

| Power Consumption: | 9,2 kW peak 2-5 kw avg. |

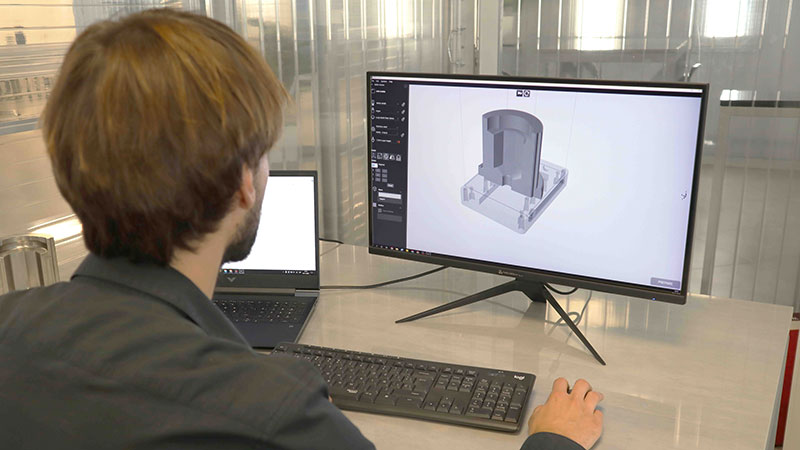

| Slicer Software: | Meltio relies on its Software Partners Ecosystem for the Hybrid process, including additive and subtractive Visit Meltio Software Partners for more info |

|---|---|

| Feeder System: | Quad-point traction servomotor feeder, frictionless liners |

| Wire Feedstock: | Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready |

| Product Configurations: | Single or Dual Wire |

| Compatible Materials: | Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium, Copper Alloys, Gold alloys and more |

Meltio Engine IR Integration kit

| Laser System: | Infrarred Laser 1200W 6 x 976 nm direct diode lasers + fibers & colimators |

|---|---|

| Printhead: | Mounted on the right side of the spindle 45 kg |

| Printhead Retracted Size (WxDxH): | 255 x 320 x 1075 mm |

| Printhead Unretracted Size (WxDxH): | 255 x 320 x 1135 mm |

| Control Unit: | Floor Mounted (Wheeled) 125 kg with 27″ HMI screen 390 x 650 x 1600 (deployed screen) |

| Cooling: | Water-cooled control unit and deposition head. Chiller included |

| Print Envelope (WxDxH): | Depending on the machining center |

| Process Control: | Closed-loop, wire modulation |

| Power Input: | 200/240 V 3W+PE 380/415 V 3W+N+PE |

|---|---|

| Power Consumption: | 2 – 5 kW peak depending on selected options |

| Slicer Software: | Meltio relies on its Software Partners Ecosystem for the Hybrid process, including additive and subtractive Visit Meltio Software Partners for more info |

|---|---|

| Feeder System: | Dual traction stepper motors + External Feeder (Push-pull system), conventional wire liners |

| Wire Feedstock: | Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready |

| Product Configurations: | Single or Dual Wire |

| Compatible Materials: | Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium and more |

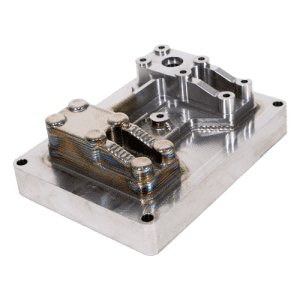

Success stories

Meltio Engine CNC integration applications

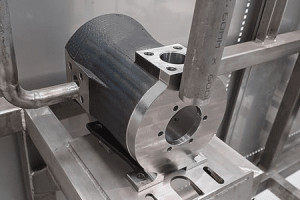

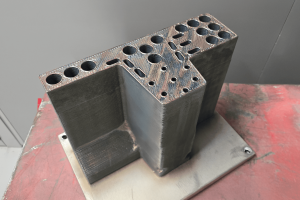

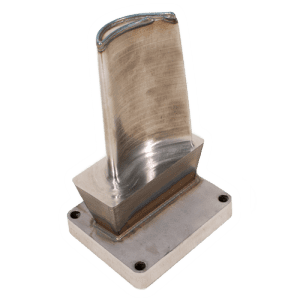

Titanium 64

| Size: | 109.6 x 160.8 x 34.8 mm |

|---|---|

|

Weight: |

1.50 kg |

|

Print time: |

13h 33′ |

Stainless Steel 316L + Nickel 625

| Size: | 73 x 48 x 17 mm |

|---|---|

|

Weight: |

Stainless Steel 316L: 1.46 kg + Nickel 625: 0.1 kg |

|

Print time: |

10h |

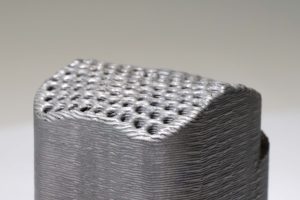

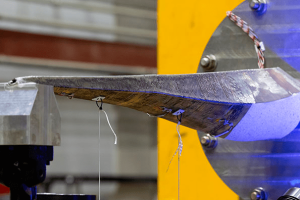

Nickel 625

| Size: | 65 x 29 x 6 mm |

|---|---|

|

Weight: |

0.015 kg |

|

Print time: |

6h 16′ |

Do you want to know more about printed part properties?

Customer validation & Success stories

Integrating Meltio into our Haas CNC machine gave us the ability to repair complex mold geometries. We machine away the damage, print new H11 tool steel, and finish it back to original tolerance—all without moving the part.

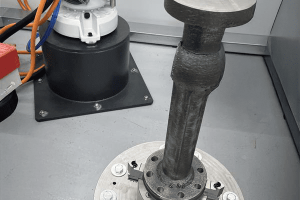

We use the Meltio Engine CNC to add features to existing forged shafts. This 'Hybrid' approach saves us from machining 90% of the material away from a billet. We only print the material we need, exactly where we need it." R&D Engineer Metal Forming Division

The Hybrid manufacturing capability is revolutionary for our pump impellers. We print the rough geometry and immediately machine it to final tolerance in the same setup. It reduced our lead time from 8 weeks (casting) to just 3 days.

The ability to 3D print stainless steel directly onboard a naval vessel allows us to maintain operational readiness at sea. Meltio’s use of standard welding wire solves the logistics problem—we don't need to carry hazardous powders, just spools of wire.

Know more about Meltio Engine CNC integration

Unlocking Hybrid Manufacturing:

Meltio Engine Blue

Watch this webinar together with Phillips Corp. and explore how cutting-edge hybrid manufacturing technology is transforming the industry.

Get a quote Meltio Engine CNC Integration

Receive a tailor-made offer

Know more about us

Check our latest news and use cases