Linares (Spain), January 17th, 2024.- Snowbird Technologies has been selected as a finalist for the 2024 Military Additive Manufacturing (MilAM) Awards for Expeditionary and Tactical 3D Printing Excellence. Thanks to its partnership with Meltio, Snowbird offers unique wire-laser metal AM solutions to create and repair reliable metal 3D printed parts for the US Army.

The MilAM Awards are given each year at the annual Military Additive Manufacturing Summit and Technology Showcase and recognize individuals, or groups, that have exemplified outstanding achievement in 3D printing in support of the US Department of Defense (DoD) mission priorities.

The awards examine not only how AM technologies are important in solving supply chain issues but are becoming vital to enhancing capabilities that will improve warfighter flexibility and readiness at the tactical edge.

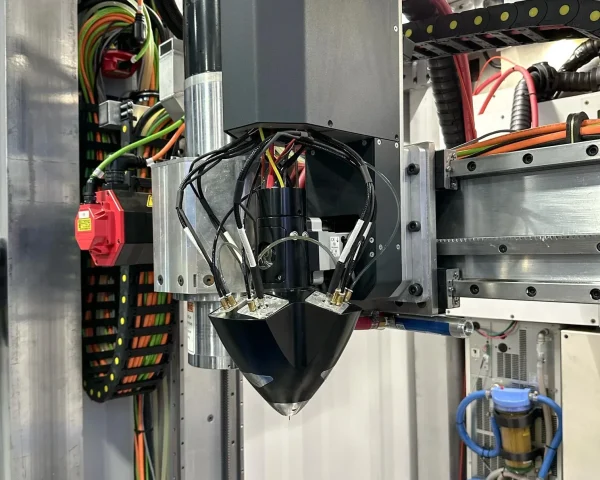

Snowbird Technologies has been selected as a finalist for the Expeditionary and Tactical 3D Printing Excellence Award for the development of the Snowbird Additive Mobile Manufacturing Technology (SAMM Tech) platform. SAMM Tech is a patented, deployable, hybrid manufacturing platform that performs metal 3D printing powered by Meltio and CNC finishing in one system.

Integrated into an intermodal shipping container, this revolutionary design allows production to be brought to the point of need, providing a solution for contested logistics and parts obsolescence in the field.

The Expeditionary and Tactical Excellence Award will be presented to a government or industry representative in recognition of their profound contributions and diligent work in delivering innovative advanced manufacturing solutions to the tactical edge.

The award is meant to drive continued efforts to supply the warfighter with enhanced AM capabilities that improve readiness and reduce the time it takes to attain a critical part.

Meltio is dedicated to the development of its unique and patented wire-laser metal 3D printing technology for the worldwide sector and has just celebrated a very remarkable milestone: exceeding 300 systems sold worldwide. The mission of the metal AM company is to provide worldwide industries with unique wire-laser metal additive manufacturing technology to create and repair reliable, high-dense metal parts (stainless steel, titanium, nickel, Inconel, and many others).

Industries such as automotive, aerospace, oil and gas, mining, research centers, universities, and others in more than 60 countries already enjoy Meltio’s solutions.

Meltio covers the needs of industries around the world in their quest for cost reduction and increased reliability in their manufacturing processes. With the installation and adoption of Meltio’s metal AM solutions, industries gain flexibility and automation of their industrial processes by being able to repair and manufacture metal parts in a user-friendly environment and with availability and access to technology 7/7 24 hours a day, a great leap from conventional manufacturing processes.

Check Meltio’s milestones during 2023: Meltio remains focused on growth.

About Meltio:

Meltio takes metal additive manufacturing to the next level by developing and manufacturing high-performance, affordable, and easy-to-use metal 3D printing solutions using wire-laser metal deposition (LMD) technology.

The company’s mission is to delight customers, partners, and employees by pioneering the development of affordable metal 3D printing systems that are reliable, safe, and powerful, continually reinforcing their status as disruptors. Meltio, based in Linares (Spain), develops and fabricates high-quality disruptive products aimed at high-profile industrial end customers and organizations, such as universities and research-oriented companies.

The current portfolio of metal solutions includes the Meltio M450 metal 3D printer, the Meltio Engine CNC Integration, which turns virtually any CNC machine into a powerful hybrid manufacturing center, and the Meltio Engine Robot Integration, which is the perfect platform for large and complex 3D printing,

repair, cladding, and feature addition. The company’s latest product launch, Meltio Robot Cell is an affordable turn-key solution for the Meltio Engine Robot Integration. All of the systems share the same patented LMD-based (a type of Directed Energy Deposition (DED) process) process capable of manufacturing parts using commodity welding wire.