After being validated by the US Army, the French Army, and the Spanish Army as well as the Spanish Air Force—along with other military forces across EMEA—the Army of the Republic of Korea has now certified Meltio’s unique wire-laser technology.

The Republic of Korea Marine Corps is the first military unit in the country to introduce robot-based metal 3D printers, enabling in-house production of discontinued and hard-to-procure parts.

Enhancing field operability by enabling vehicle mobility, while also reducing costs and ensuring stable maintenance support.

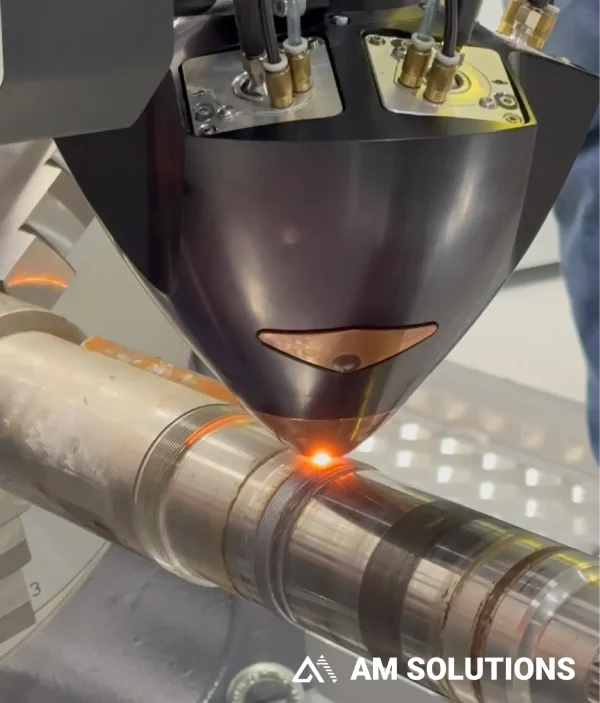

Photo credits: Republic of Korea Marine Corps amphibious vehicle maintenance crews demonstrate additive manufacturing capabilities using a robot-based metal 3D printer. Courtesy of the unit.

Yuseong-gu, Daejeon (Republic of Korea) / Linares (Spain), March 26, 2025.– After being validated by the US Navy, the French Navy, and the Spanish Army as well as the Spanish Air Force, along with other military forces across EMEA, the Republic of Korea Marine Corps (South Korea) has now certified Meltio’s unique wire-laser technology.

Additionally, this marks the first time the Army of the Republic of Korea has decided to integrate metal additive manufacturing solutions for spare parts and repairs, gaining autonomy over conventional and more costly manufacturing processes. This achievement has been made possible through the collaboration agreement between Meltio and AM Solutions, which has enabled the extension of this initiative to the Korean army.

According to an extended article published by the South Korean magazine Kookbang and confirmed by our partner, AM Solutions, the Republic of Korea Marine Corps is the first in the entire military to use robot-based metal 3D printers for logistics support. As a result, it has become possible to quickly manufacture repair parts that are discontinued or difficult to procure. It is expected that field maintainability will also be greatly improved as it can be moved by crane or forklift.

Lieutenant Colonel Kim Seong-nam of the Republic of Korea Marine Corps, commander of the maintenance battalion, said, “The introduction of metal 3D printers is significant not only for reducing operation and maintenance costs, but also for preventing delays in maintenance schedules due to limited procurement of repair parts,” he emphasized his commitment, stating, “We will maintain the best logistics support system to enable stable maintenance support.” Cho Soo-yeon, Reporter.

Daejung Kim, AM Solutions CEO, said, “the successful introduction of Meltio’s outstanding technology into the Republic of Korea Marine Corps marks a significant milestone in local manufacturing innovation. He also conveyed that this entry into the defense sector is just the beginning, and through a continuous partnership with Meltio, they aim to lead Republic of Korea’s advanced industries in other sectors requiring additive manufacturing.

Adam Hourigan, Meltio Sales manager for APAC region, said, “The defense sector is strategic for Meltio. Our technology is being validated by armies all over the world and for us it is very positive that thanks to collaboration agreements with relevant partners in Asia such as AM Solutions we are able to help with our different 3D metal wire welding printing solutions the army of the Republic of Korea to gain autonomy in manufacturing and creating metal parts in a reliable and sustainable way.”

“It has become possible to quickly manufacture repair parts that are discontinued or difficult to procure.”

The Republic of Korea Marine Corp’s announcement:

On the 19th of February, the Republic of Korea Marine Corps announced, “We have introduced a container-type mobile metal 3D printer to quickly and smoothly provide logistics support, such as manufacturing parts in-house to cope with the limited procurement and discontinuation of repair parts for Marine Corps-specific equipment, including the amphibious assault armored vehicle (KAAV).”

Although various military branches have used 3D printers to manufacture discontinued maintenance and repair parts, The Republic of Korea Marine Corps is the first to implement a robot-based mobile 3D printer.

The Meltio metal 3D printer introduced in this initiative utilizes the Laser Wire Directed Energy Deposition (LW-DED) method. This advanced metal Additive Manufacturing (AM) technology works by melting metal wire with a laser beam and layering it to form a three-dimensional structure. Compared to other metal AM techniques, DED technology significantly reduces material waste, making it a cost-effective solution for manufacturing. Meltio systems are capable of reliably producing metal parts using Stainless Steel, Titanium, Copper, Inconel, and a wide range of other metal alloys.

Thanks to AM Solutions, Meltio offers the Korean Army its unique Meltio Integration Kit for Industrial Robots. This system turns an industrial robot arm into a metal 3D printing system eliminating inherent size constraints, allowing for large-scale metal 3D printing, including complex geometries. It is the ideal platform for large-scale 3D printing, repair, cladding, and adding features to existing parts.

The Meltio Engine seamlessly integrates with nearly any robotic arm manufacturer and interface available on the market. Its Meltio Space slicer software for robotic systems is fully compatible with ABB, Kuka, Fanuc, Yaskawa.

Another strength is that it has improved ‘field operability’ by allowing maintenance while moving in a vehicle. This is why metal 3D printers are used in the maintenance of the Marine Corps’ main combat assets.

The Republic of Korea Marine Corps plans to expand its maintenance support capabilities by operating and proficient in equipment over the next two years and expanding support equipment for field operations, such as mobile metal precision processing machines and generators.

Meltio, the trusted choice for armies around the world

This is not the first time a military force has adopted Meltio’s 3D printing technology, as the US, French, and Spanish militaries are already utilizing it. A key demonstration of its success took place aboard the USS Bataan, where a 3D-printed part was produced using Meltio’s hybrid manufacturing system, which integrates with a CNC milling machine.

Producing spare parts at sea presents a significant challenge, especially given the limited space onboard and the obsolescence of many decades-old components. The USS Bataan is addressing this issue by becoming the first U.S. Navy ship to deploy a hybrid manufacturing system featuring Meltio’s deposition head on a milling machine, providing sailors with industrial-grade manufacturing capabilities directly onboard.

See different Meltio solutions for Defense armies: https://meltio3d.com/meltio-defense/

Meltio’s technology enabled the production of a 3D-printed metal replacement sprayer plate for a ballast air compressor (DBAC) in just five days—far faster than the weeks required through conventional Navy supply channels. This achievement earned Meltio the XTechInternational award, recognizing it as a “strategic technology partner” in military and security development.

The French Navy has validated Meltio’s solutions for manufacturing and repairing metal parts, successfully using the M450 printer to produce stainless steel components for the aircraft carrier Charles de Gaulle.

Meanwhile, in Spain, Meltio is supporting the Spanish Air Force in jet engine repair using titanium and copper-based alloys, and assisting the Spanish Army in manufacturing stainless steel spare parts for armored vehicles.