Manufacturing autonomy

where it matters most

From remote mining sites to offshore platforms, Meltio’s wire-laser metal 3D printing technology brings unmatched reliability, flexibility, and cost-efficiency to the toughest industrial sectors.

Forget about supply chain delays, drastically cut down the costs of custom parts and reduce the equipment downtime to a minimum.

Faster lead times and lower costs

Enable manufacturing autonomy by on-site production and repair in remote locations, reducing the logistics burden and therefore costs and time.

On-site print and repair

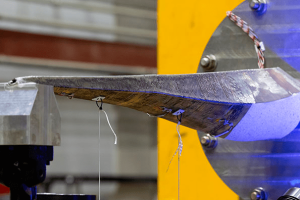

Create and repair parts directly at the point-of-need, even in remote locations. Repair damaged components to turn them fully operational again.

Avoid supply chain delays

No need to wait weeks to receive a component anymore. No need of stock either.

Cut costs and downtime

Greatly reduce the high costs for custom or complex parts. Improve the production process by cutting the equipment downtime impacting productivity.

Reduce material waste

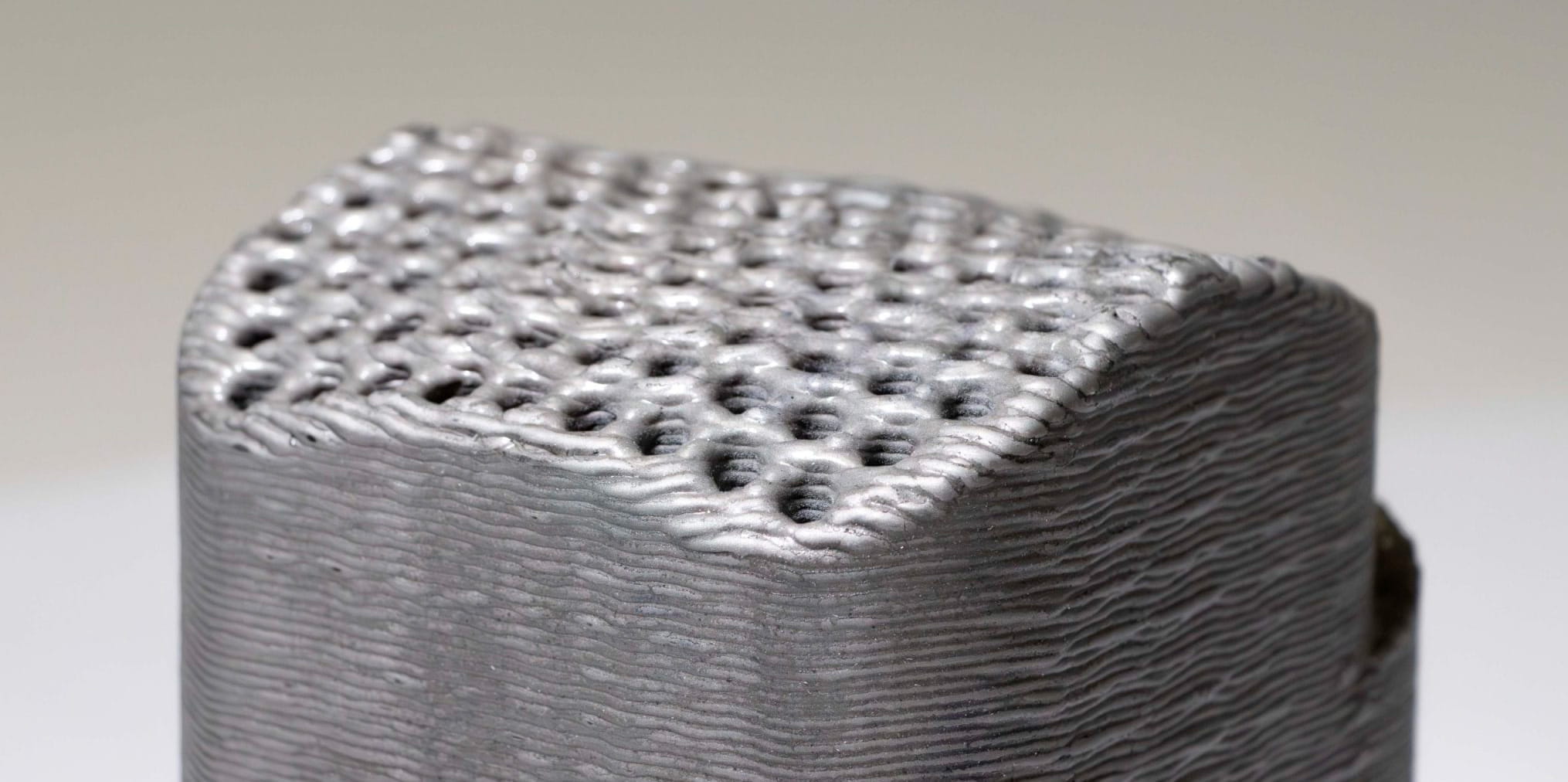

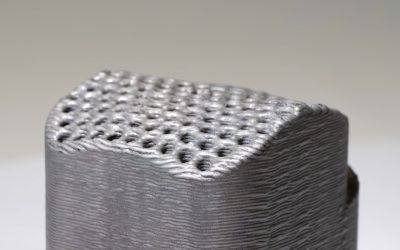

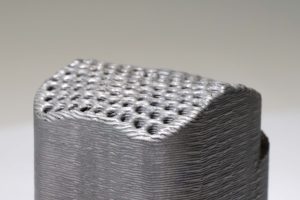

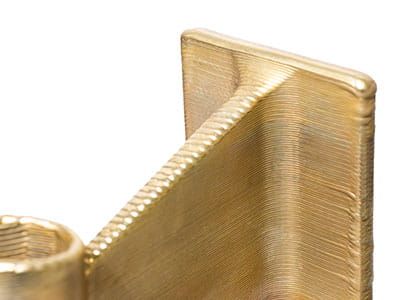

Near-net-shape manufacturing with no excess material. Wire is the safest, cleanest and more reliable feedstock.

Customer validation & Success stories

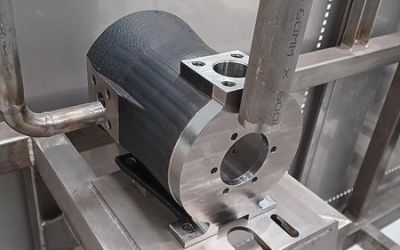

Meltio was the only out-of-the-box industrial wire-laser metal AM solution capable of printing multiple materials with a wide variety of options. Powder 3D printing didn’t fit our needs, and the Meltio solution was the only standalone wire metal printer that allowed us to successfully produce a complex turbine case with internal structure, all in a single print and just one prototype.

Our investigated cross sections demonstrate very solid material quality. The bonding between the pre-machined flange and the printed pipe is excellent, showing no fusion issues under microscopic examination. The overall construction remains robust. Some natural variations in wall thicknesses and diameters were observed, which are within acceptable tolerances. Surface roughness across different areas is consistent.

Implementing Meltio’s wire-laser metal 3D printing has allowed us to manufacture and repair wear components with complex geometries that would be uneconomical using our traditional supply chain. We’ve also reduced our inventory risk by printing on-demand, closer to site.

Meltio applications for the

Mining, Oil & Gas sectors

Download Meltio’s Brochure for Mining, Oil & Gas

A deployable solution: Self-sufficiency and readiness for a point-of-need and a time-of-need

Our systems are already deployed due to their reduced ambient requirements, allowing for operation in open environments without the need for specialized enclosures. This makes Meltio an ideal solution for in-field repairs, rapid part replacement, and advanced manufacturing of structural or subsystem components.

Part repair and on-demand manufacturing capabilities in remote or operational areas

Decrease reliance on supply chain and required stock materials

Valuable assets for manufacturers: Portability, ease of use and compatibility with existing resources

Tele-operation compatible

Deployable Hybrid Manufacturing Center

- Reverse osmosis pump bushing

- New part was printed and machined faster

- Saving time, money, space, and increasing overall warfighter readiness

- By Meltio’s partner, Snowbird

Container

- Spare parts manufacturing

- Legacy components replacement

Container Mobility System

- Cargo ship Membrane Tank

- Spherical Tanks

- Aerospace components

- By Meltio’s partner, AM Solutions

Do you need help?

Reach out! We’d love to hear about your project.