Manufacturing 35% lighter titanium uprights for Formula Student

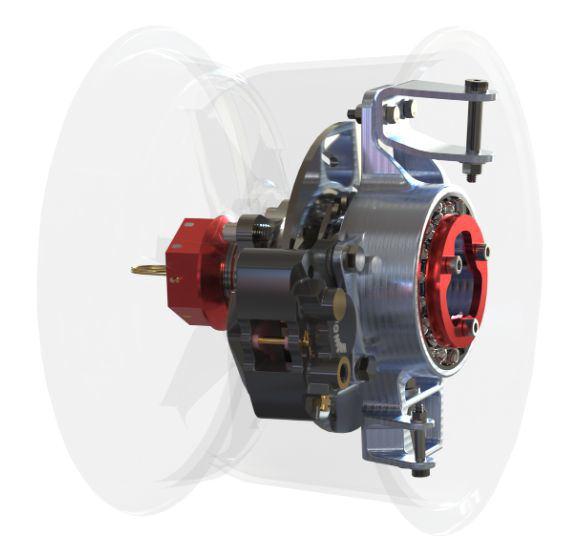

In Formula Student, engineering compromises are not an option; they are the difference between the podium and the paddock. For the Málaga Racing Team (MART), the 2025 season brought a massive architectural shift: the transition to a fully electric powertrain for their new challenger, the MA25RT.

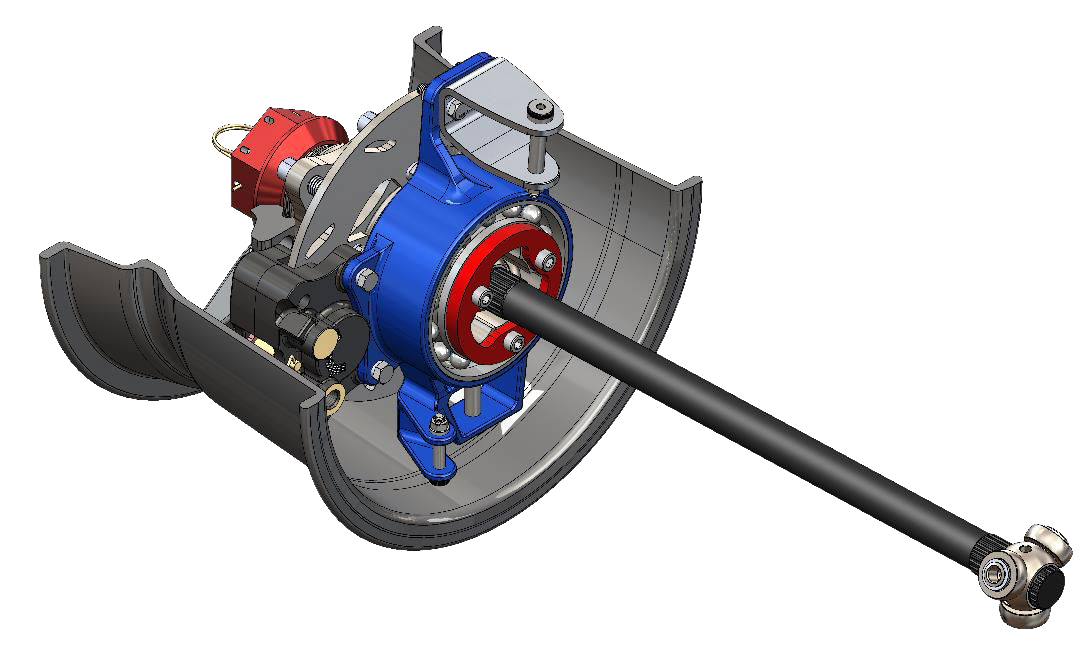

Electric drive offers superior torque and acceleration, but it comes with a heavy penalty: the battery pack. To keep the car competitive, the team had to aggressively shed weight elsewhere. They identified the Rear Upright (or wheel carrier) as the primary candidate for optimization.

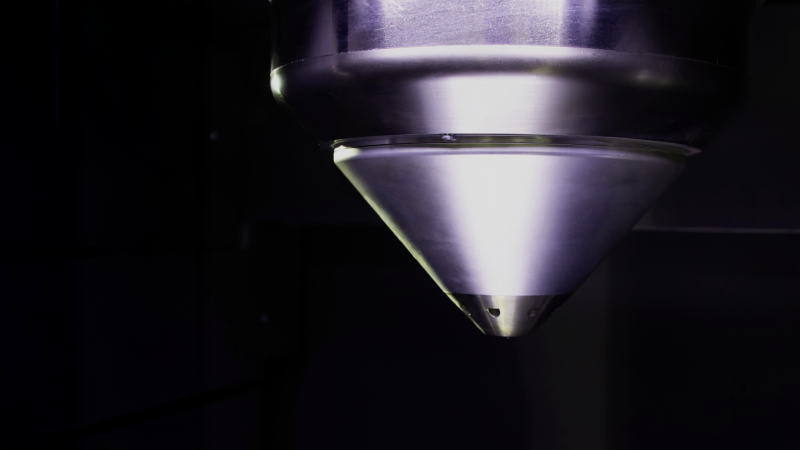

This component is the structural link between the suspension and the road. It endures punishing braking, cornering, and vertical loads. MART turned to Meltio’s Wire-Laser Metal Deposition (LMD) technology to achieve what traditional machining could not: a drastic reduction in mass without compromising stiffness.

Formula Student, also known as Formula SAE, is an international motor racing competition between universities that promotes excellence in engineering through the study, design, development and manufacture of a single-seater racing car. Universities from around the world take on the challenge of building an open-wheel car to compete in a series of static and dynamic tests that push the limits of the future bright minds of engineering.

In 2016, a group of 15 engineering students embarked on the adventure of creating their own Formula Student team at the University of Malaga. This led to the creation of MART FS, a racing team run entirely by students who, after years of novelty, motivation and uncertainty, managed to present their first complete single-seater in 2021.

“This collaboration not only allowed us to enhance the performance of our race car but also to massively expand our knowledge of one of the most promising technologies shaping the future of manufacturing.»

MART Team

1. The limits of CNC machining for complex geometries

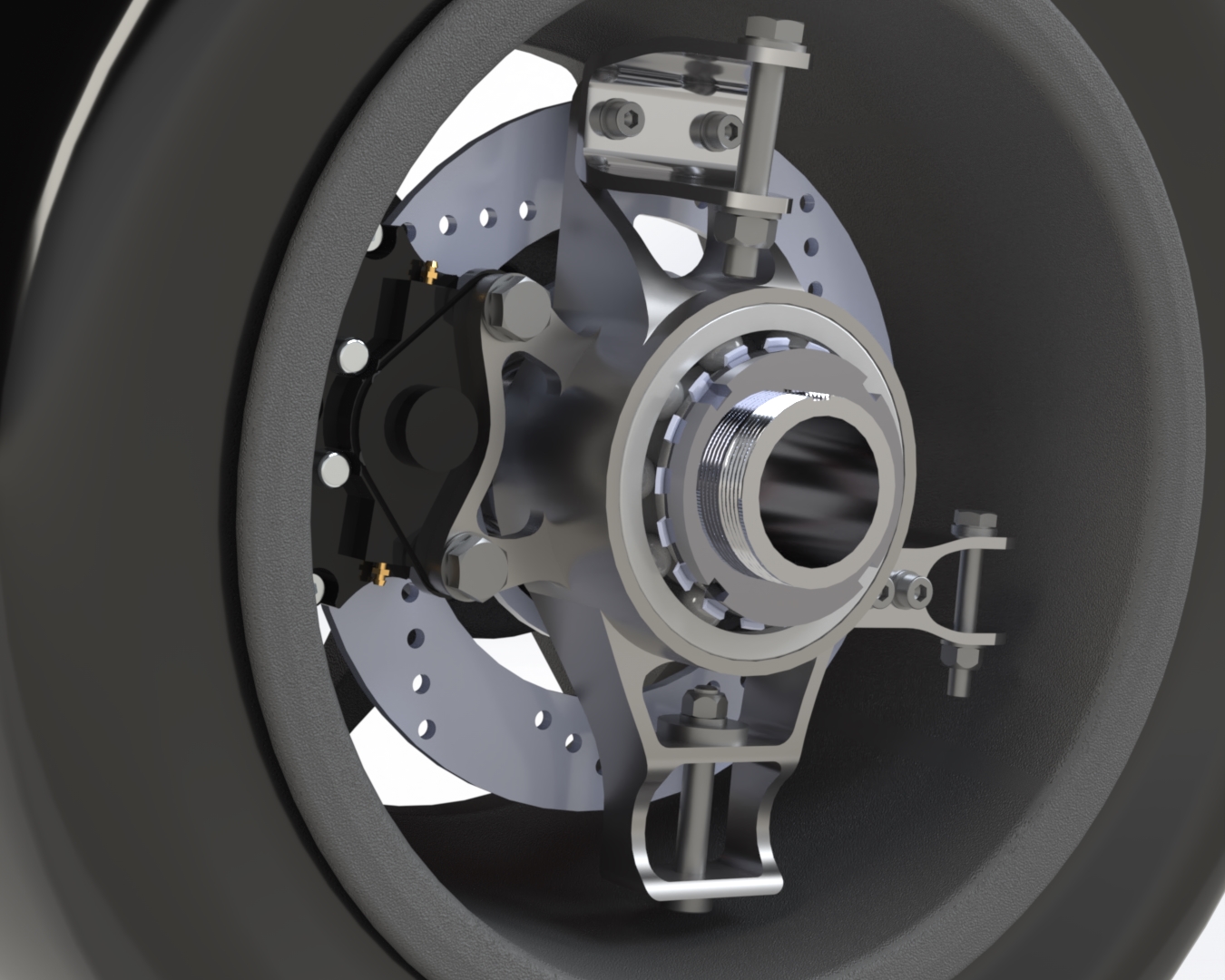

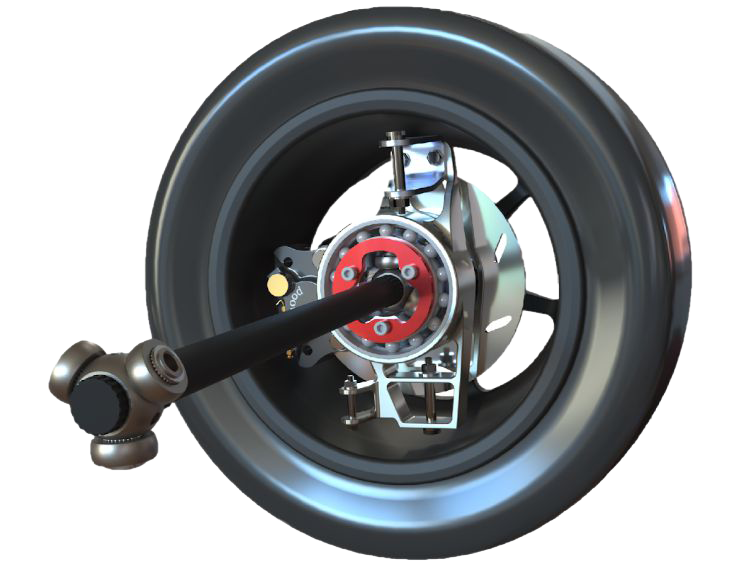

The upright is part of the vehicle’s unsprung mass, components not supported by the suspension (wheels, uprights, brakes). In vehicle dynamics, unsprung weight is the enemy.

The team uses a classic engineering analogy:

«Think of an athlete and their footwear; the lighter the shoes, the faster the reaction.»

The multiplier effect

In Formula Student vehicles, reducing 1 kg of unsprung mass is dynamically equivalent to removing roughly 25 kg of sprung mass (chassis/body).

The CNC limit

Previous uprights were CNC-machined from aluminum blocks. While reliable, this subtractive method limited geometric freedom. To remove more material, machining time and costs would skyrocket, and the risk of reducing stiffness was too high.

MART needed a material with a higher strength-to-weight ratio than aluminum and a manufacturing method that could place material only where the load paths required it.

2. Moving from block machining to organic shapes

The team selected Ti-6Al-4V (Grade 5 Titanium). It offers the strength of steel at roughly 60% of the density and provides superior fatigue resistance compared to aluminum.

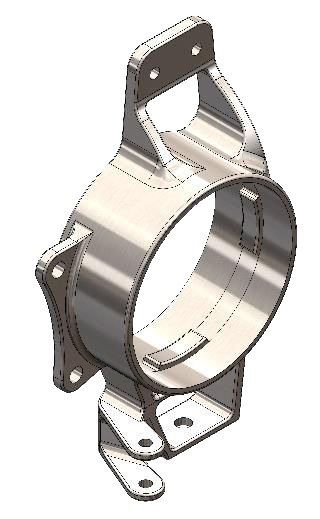

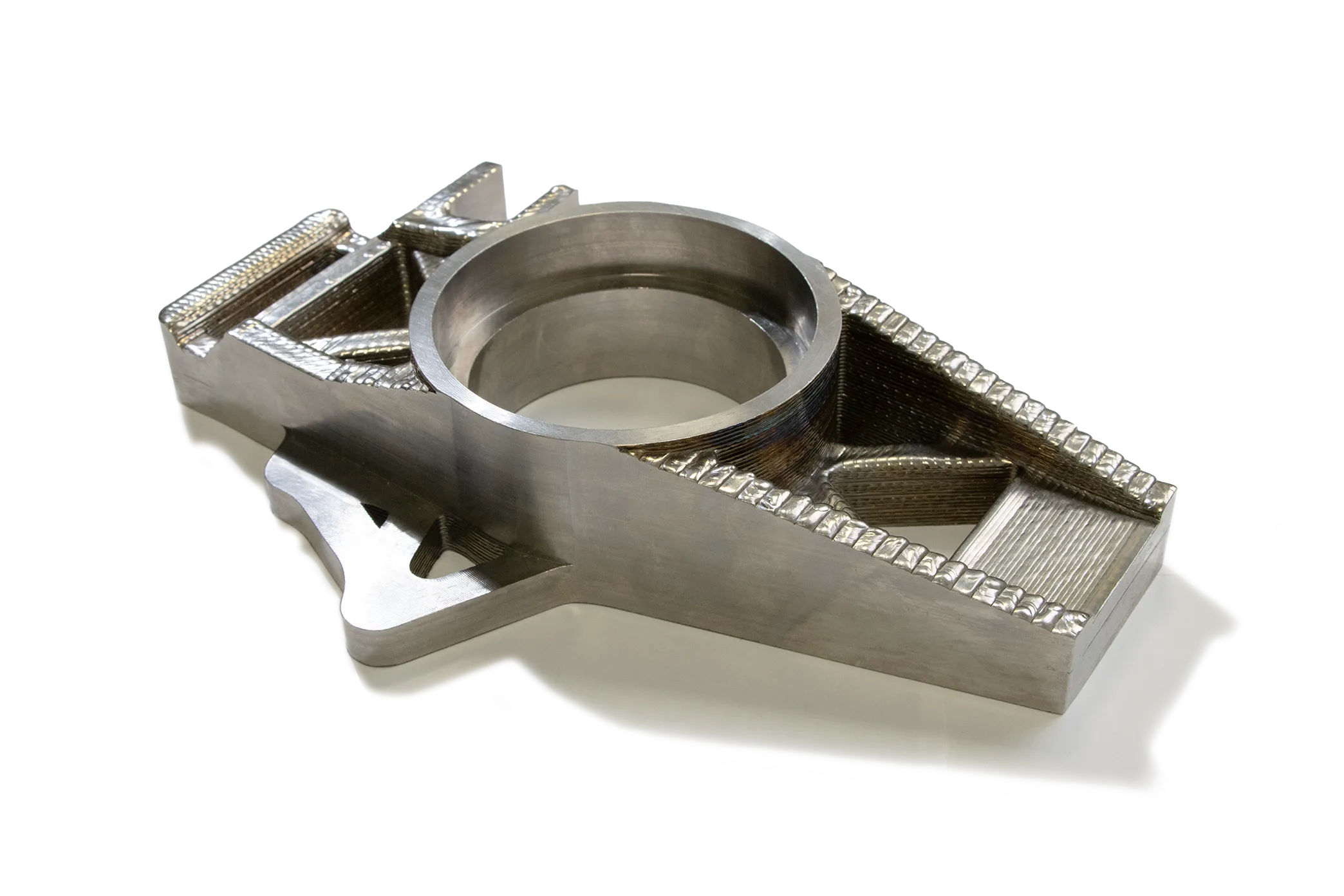

However, Titanium is notoriously difficult and expensive to machine from a billet. The challenge was to utilize Design for Additive Manufacturing to create a «near-net-shape» part that required minimal finishing.

The engineering constraints were tight:

Complex geometry

The part houses bearings and connects to multiple suspension links, requiring varying wall thicknesses and overhangs.

Thermal management

Titanium has low thermal conductivity. Using LMD, the team had to manage the heat input to prevent residual stress distortion during the print.

Hybrid manufacturing

The printed part still needed precision CNC machining for bearing races and mounting points. The design had to accommodate clamping fixtures for a part that no longer had flat, square surfaces.

3. Leveraging LMD for Titanium fabrication

The true test of any engineering change in motorsport isn’t just in the design files, it’s on the scale and, ultimately, on the track. For the Málaga Racing Team (MART), the shift from traditional CNC machining to Meltio’s Wire-Laser Metal Deposition (LMD) for their rear uprights delivered immediate, quantifiable performance gains for the new electric MA25RT challenger.

Beyond performance, the project validated a more sustainable manufacturing method. Machining these complex organic shapes from a solid Titanium billet would have resulted in massive material waste (chips). By using Meltio to print a «near-net-shape» part—which only required minor CNC finishing for bearing races and mounting points—the team drastically improved their buy-to-fly ratio (the ratio of raw material weight to final part weight), making the use of high-grade Titanium economically viable for a student team.

4. Achieving a 2.5kg reduction per wheel assembly

The switch to Meltio technology allowed MART to move from a standard mechanical assembly to a highly optimized, high-performance component. The data speaks for itself:

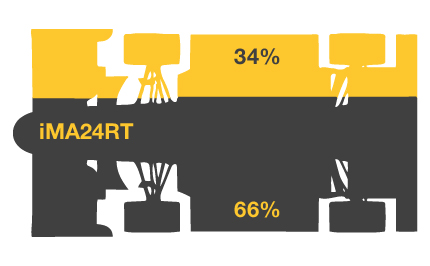

Mass reduction

The rear upright weight dropped from 725g (iMA24RT) to 470g (MA25RT). This is a 35% reduction in a single component.

System savings

The total weight of the rear wheel assembly was reduced by 2.5 kg per wheel (from 9.69 kg to 7.19 kg).

Dynamic response

The driver reported immediate feedback improvements during track testing, citing sharper turn-in and better suspension compliance over bumps.

Material effiency

By printing near-net shape, the buy-to-fly ratio (raw material vs. final part) was drastically improved compared to machining a solid Titanium billet.

“The implementation of Meltio’s LMD technology has transformed the way MART FS approaches both design and production. The possibility of manufacturing geometrically complex titanium parts directly from digital models allows for full exploitation of Design for Additive Manufacturing (DfAM) principles, reducing weight, consolidating multiple components into single parts, and improving stiffness-to-weight ratios.

This directly translates into enhanced vehicle performance by reducing unsprung mass, improving dynamic response, and optimizing packaging within the car’s wheel assemblies.»

MART Team

Expand your manufacturing capabilities with blue lasers, a large build volume, and a fully inert chamber for the best material properties. Printing is easier than ever thanks to the improved process control, advanced sensors and live monitoring allowing you to produce parts consistently 24/7.

The Meltio M600, with its built-in 3-axis probing system and work-holding solutions, is the ideal companion for your manufacturing operations.

Expertly engineered for exceptional performance and reliability.

Wire feedstock proves more affordable and safer than powder-based alternatives.

5. Validating Meltio’s LMD for critical structural parts

For MART, Meltio was not just a manufacturing alternative; it was a strategic enabler for their electric vehicle transition. They successfully validated that wire-laser metal 3D printing is not just for prototyping; it is a viable production method for critical, high-load structural components in motorsport.

By leveraging LMD, they solved the unsprung mass problem, utilized high-performance Titanium without the prohibitive waste of machining, and secured a competitive edge for the 2025 Formula Student season.

To know more about this use case, click HERE

FAQs

Titanium Grade 5 offers a much higher strength-to-weight ratio than aluminum. It creates parts with the strength of steel but at roughly 60% of the density. This allowed the team to design thinner walls and more complex, organic geometries that would be impossible or too fragile if machined from aluminum.

Yes. We utilized a Hybrid Manufacturing approach. The part was printed to "near-net shape" using the Meltio system (achieving the complex geometry), and then precision CNC machining was used to finish the critical interfaces—specifically the bearing housings and suspension mounting points—to ensure perfect tolerances.

EVs in Formula Student struggle with the heavy weight of the battery pack. To keep the car competitive, weight must be shed elsewhere. Reducing the weight of the uprights helps offset the battery mass, keeping the car agile despite the electric powertrain.

Absolutely. The printed Titanium parts have excellent mechanical properties, comparable to cast or forged materials when printed correctly. The uprights successfully handle the extreme forces of braking, cornering, and vertical loads experienced on the track.

Meltio’s wire-based process is cleaner, safer, and generally more cost-effective for parts of this size. It avoids the safety hazards of handling reactive Titanium powder and allows for printing directly onto a substrate, which simplifies the workflow for a university team.