The aerospace sector is governed by a relentless pursuit of efficiency, not just in aerodynamic performance, but in manufacturing logistics. For components like turbine jet engine housings, the traditional reliance on offshore suppliers and solid billet machining creates vulnerabilities in both supply chain resilience and material utilization.

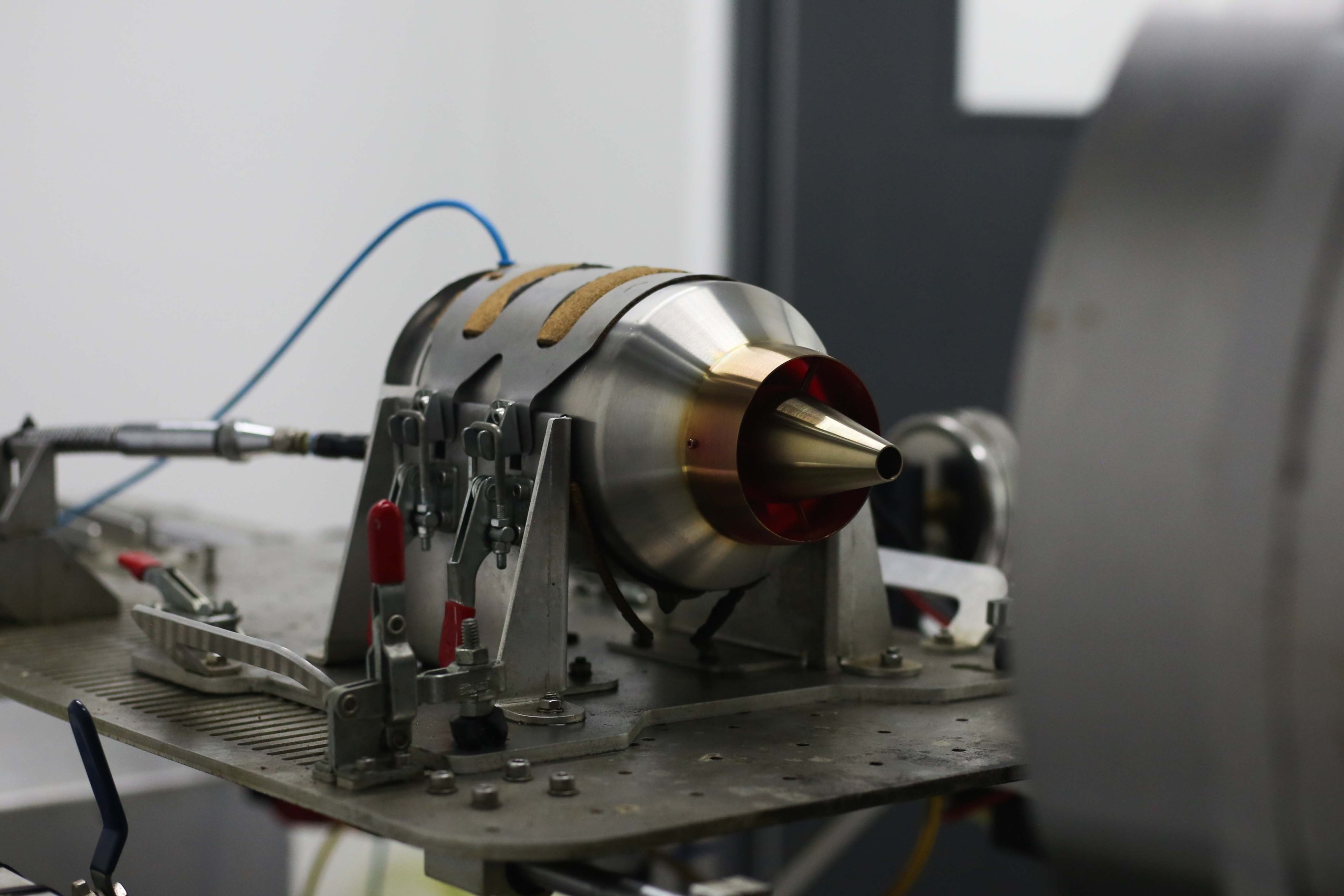

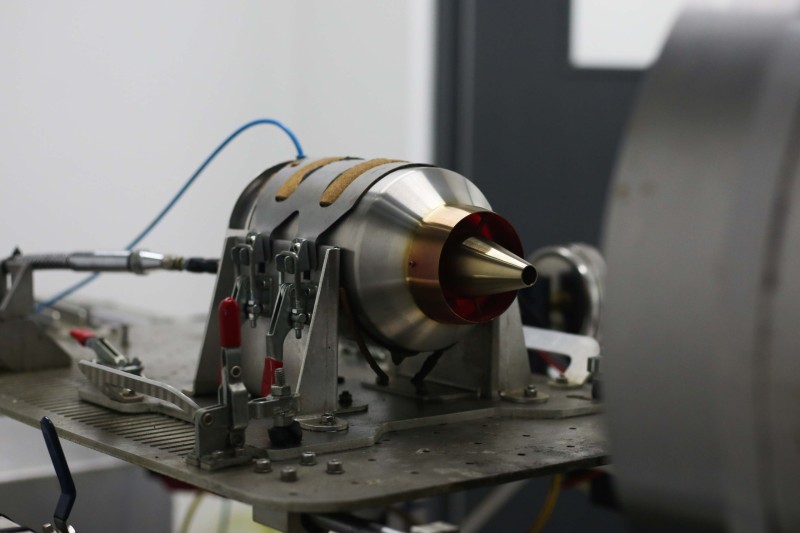

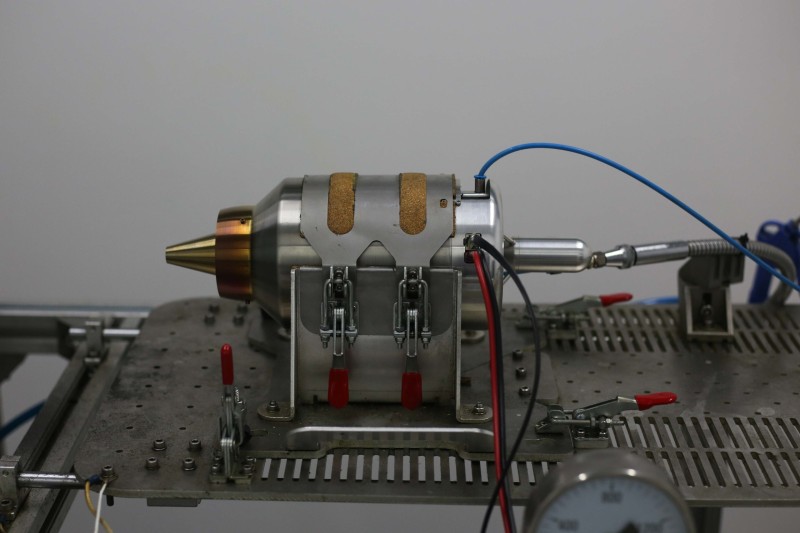

In collaboration with reseller AMT 3D, manufacturer HH Industries utilized Meltio’s engine housing application to address these specific industrial pain points. This project validates the transition from conventional subtractive methods to a hybrid wire-laser metal 3D printing workflow. By integrating additive deposition with standard CNC machining, engineers can now secure critical propulsion components locally, reducing dependency on volatile external logistics.

«The decision originated from the need to overcome high material waste, long lead times, and cost inefficiencies inherent in conventional machining of high-value alloys.»

1. The high cost of traditional billet machining

The standard manufacturing protocol for a turbine housing involves machining the geometry from a solid block of metal. This subtractive process results in a high «buy-to-fly» ratio: The ratio of the mass of the raw material purchased to the mass of the final flight-ready part.

For HH Industries, relying on conventional machining presented three distinct friction points:

1. Excessive waste

Removing large volumes of material to reach the final geometry is inherently inefficient.

2. Material cost

When dealing with aerospace-grade materials, the cost of the wasted swarf (chips) significantly impacts the bottom line.

3. Lead times

Sourcing large billets and the subsequent machining hours extends the production timeline, delaying project completion.

2. Balancing material performance with production economics

The specific challenge was to produce a turbine jet engine housing that met aerospace quality standards while drastically reducing the economic and logistical footprint of the part. The goal was not merely to print a part, but to prove that a hybrid approach could yield a «near-net-shape» component capable of withstanding operational stresses.

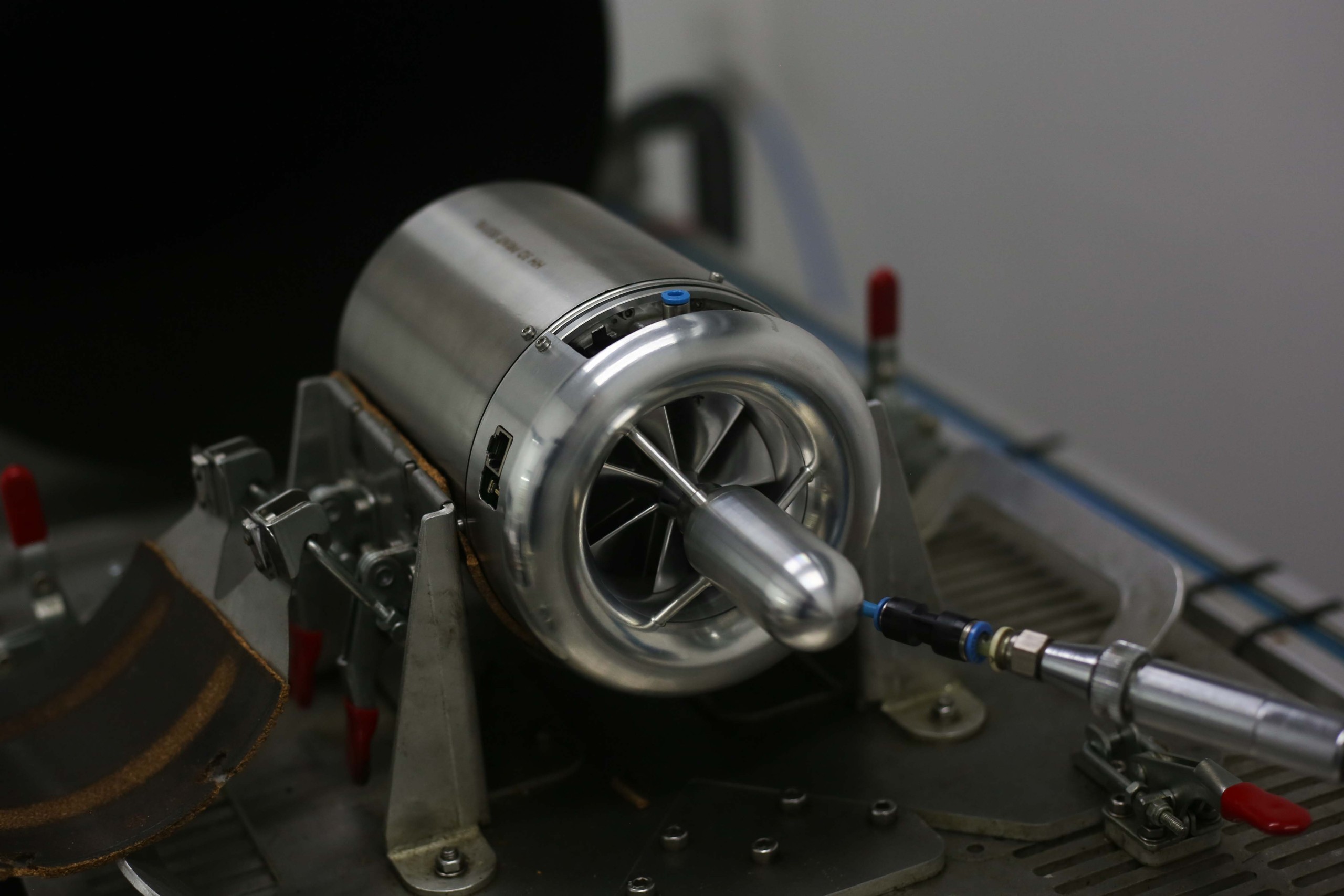

3. Leveraging the Meltio M600 for industrial reliability

HH Industries selected Meltio’s industrial wire-laser metal AM solution for its robustness and specific capability in hybrid manufacturing.

The technical process involved:

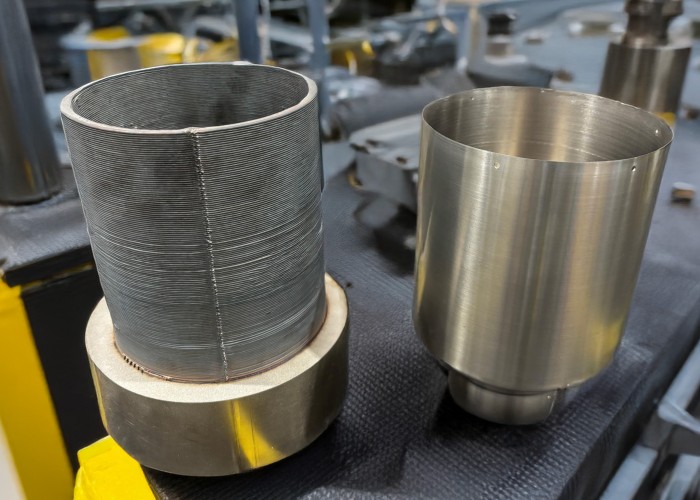

Substrate strategy

Instead of printing from zero, the system deposited SS316L wire directly onto a pre-machined billet substrate.

Near-net-shape deposition

The Meltio head deposited material only where necessary to form the housing's geometry, creating a hybrid part that required minimal finishing.

Material efficiency

By using wire feedstock, the process ensured 100% material capture efficiency in the deposited zones, improving safety and handling compared to powder-based systems.

“On the Meltio M600 the part can be printed on a billet that forms part of the final part so a hybrid part is output at the end.»

4. Quantifiable savings and supply chain resilience

The shift to Meltio’s hybrid application delivered immediate technical and commercial ROI for HH Industries:

Cost reduction

The project demonstrated a saving of roughly 100€ in machining time and material for the SS316L part. While significant for steel, the projected savings for Titanium 64 are exponential, as the reduction in waste for such expensive alloys makes conventional machining economically unviable by comparison.

Design flexibility

The technology opens the door for functionally graded parts, using two compatible materials in a single build to optimize thermal or structural properties in specific zones.

Supply chain sovereignty

This approach enables local production of critical components, reducing reliance on offshore suppliers and mitigating logistics risks.

Process efficiency

The hybrid workflow significantly reduced machining time and lead times compared to starting with a solid billet.

Expand your manufacturing capabilities with blue lasers, a large build volume, and a fully inert chamber for the best material properties. Printing is easier than ever thanks to the improved process control, advanced sensors and live monitoring allowing you to produce parts consistently 24/7.

The Meltio M600, with its built-in 3-axis probing system and work-holding solutions, is the ideal companion for your manufacturing operations.

Global supply chain disruptions threaten defense readiness. Meltio provides the solution: on-demand metal part production with autonomous Wire-Laser Metal 3D Printing.

Our technology combines safety, reliability, and easy integration.

Wire feedstock proves more affordable and safer than powder-based alternatives.

5. The future of Aerospace manufacturing is hybrid

The collaboration between AMT 3D and HH Industries confirms that wire-laser metal 3D printing is a mature solution for low-to-medium volume aerospace production. By adopting a hybrid additive-subtractive workflow, manufacturers can bypass the constraints of traditional billet machining.

The future evolution of this application is clear: further design optimization to reduce printed volume even more, and the qualification of higher-temperature aerospace alloys. For engineers looking to optimize the buy-to-fly ratio of high-value components, Meltio provides a proven, industrial pathway.

FAQs

Meltio is best recommended for low-to-medium volume production, particularly for high-value parts where design optimization and material efficiency outweigh the need for high-volume mass production rates.

Yes. While this case utilized SS316L, the technology is specifically advantageous for high-value materials that are difficult to machine, such as Titanium 64 and Inconel 718.

Wire-laser technology was chosen for its flexibility, scalability, and safety. It allows for direct deposition onto billet substrates (hybrid manufacturing) which is often not economically feasible with powder-bed fusion systems for large components.