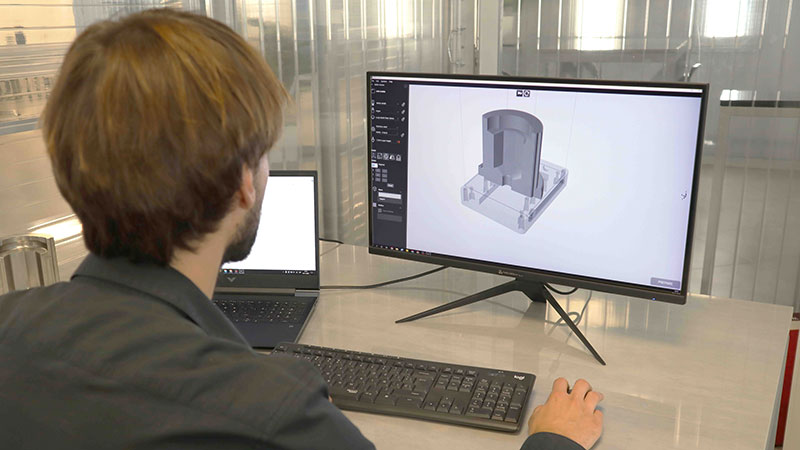

Meltio offers its proprietary toolpath generator software, Meltio Horizon, which provides a user experience tailored around its plug-and-play metal 3D printer, the Meltio M450. The new software uses the laser-wire metal deposition process with the Meltio M450. Meltio users had previously been reliant on third-party fused filament fabrication (FFF) slicers to prepare toolpaths for the Meltio M450.

In addition to traditional slicing parameters used in FFF software such as layer height, line width, print speed and support materials, the new Meltio Horizon provides access to Meltio’s laser-wire process, as well as material-specific parameters such as laser power, dual wire and hot wire settings.

With the Meltio Horizon software, all of the material-related settings are directly in the slicing software, enabling for full control and a single profile. This also enables users to create more specialized printing profiles, with the power to directly control the laser and hot wire on a per-slicing-feature basis, rather than being set for the full part.

This slicer is currently only compatible with the Meltio M450 metal 3D printer. For Meltio engines (CNC and robot integration), the company is currently working on developing its open software ecosystem partnerships that allow the generation of five-axis G codes.

Main features of the Meltio Horizon:

The Meltio Horizon is a proprietary slicer that ensures a fully tailored customer experience around our plug-and-play metal 3D printer, the Meltio M450 with its own unique features and custom-developed Meltio print and material profiles included.

- Easy-to-use: only settings relevant to Meltio’s laser-wire metal 3D printing process are available. Also, specific settings are explained to make getting started with the printing process as smooth as possible.

- Future proof: building a dedicated platform for toolpath generation specific to Meltio enables to expand the scope of our service in the future, through the incorporation of simulation or other advanced features.

- Tailor-made to laser-wire: made to measure for Meltio’s wire-laser metal 3D printing process as well as it also comes with built-in profiles for the Meltio Materials.

- Combined material profile (previously split between printer and slicer – now all is in the slicer).

- Custom gas profile: configure your gas source and cost directly within Meltio Horizon. Flow rates are defined within each material.

- Custom build plates / work spaces: select the right substrate right from the slicer depending on the part size. Build plates can be defined by the user and stored as presets. The machine workspace adjusts automatically, notifying the user if a selected build plate is too small.

- Automatic updates of the Meltio Horizon, and printing profiles: Updates of the Meltio Horizon and new printing parameters are available directly through the slicer. New Meltio Materials and printing profiles will be released periodically.

- 2D and 3D previews: to provide a good insight into the model to be printed, the Meltio Horizon provides both a 2D and a 3D preview of the toolpath. The 2D plan vision allows for easy inspection of the toolpath throughout the model.

- Project files incorporated: the complete project file, consisting of the model file, workspace, build plate as well as gas and material profiles can be conveniently stored and shared.

Wire-laser Metal 3D Printing Specific Features:

- All parameters that are shown are relevant for wire-laser 3D printing

- Based modifiers for wire-laser critical parameters

- Varying wire-laser process parameters based on part feature