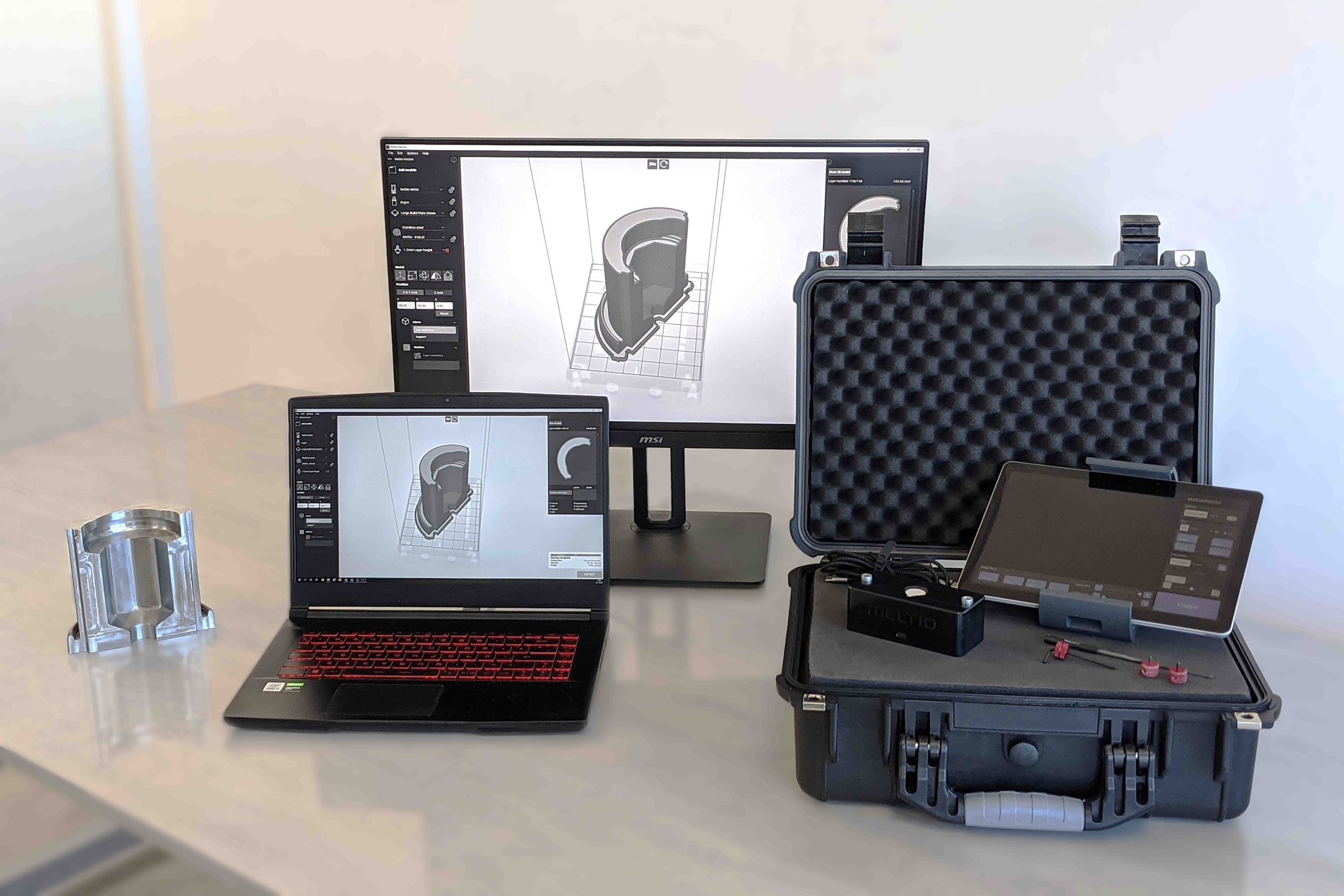

Meltio Software Ecosystem

Proprietary slicers & Open CAM integration

Verified toolpath strategies for Wire-Laser DED

Industrial software solutions to get the most out of Meltio metal additive manufacturing

Streamlines 3D printing workflow

Easily adjust your software usage to match your production requirements, ensuring cost-efficiency and scalability.

Automatic updates

Access to the latest technology Meltio software updates continuously, keeping you ahead with innovative features and improvements for metal 3D printing.

Reduce programming time

Meltio slicers are designed for speed and simplicity, cutting unnecessary steps and enriched with built-in knowledge to streamline your workflow.

Custom print profiles and work spaces

Beyond ready-to-use profiles for hollow and solid geometries, you can freely adjust parameters for full autonomy in your developments.

Accelerated workflow: From CAD to part in minutes

Our main focuses are ease of use, reliability, and affordability, allowing Meltio technology to be a game-changer in the metal industry.

Slicer for the Meltio M600

Industrial Printer

Meltio Horizon is a proprietary toolpath generator designed for 3-axis metal 3D printing, optimized for our laser-wire deposition process with the Meltio M600 metal 3D printer.

State-of-the-art

Robot toolpath generator

Meltio Space is a slicing software for Meltio Engine Robot Laser Integration kit, featuring an intuitive interface for planar, non-planar, and variable extrusion toolpaths, compatible with leading industrial robot brands.

Additive toolpath generation for CNC machines

Validated software solutions for specific CNC hybrid configurations of the Engine CNC Laser Integration Kit, including unique post-processors and M-codes for seamless communication between the Meltio Engine and the CNC controller.

The Open Software strategy

Meltio believes in an open architecture. While we offer powerful proprietary slicers (Horizon & Space) for quick-start production, we collaborate with the world's leading CAM developers to ensure advanced users can program Meltio systems using their existing software infrastructure."

Proprietary software for standalone and Robotic systems

As of 2025, Meltio offers proprietary software solutions for the standalone printer Meltio M600 through Meltio Horizon and for robotic integrations with Meltio Space. These solutions provide process knowledge and ease of use for the Meltio process.

Meltio Horizon: Optimizing metal 3D printing

Meltio Horizon for the Meltio M600 enhances 3-axis metal 3D printing with our laser-wire deposition process. This software offers valuable resources like printing profiles, material datasheets, and verification tools to ensure smooth operation of Meltio systems.

Meltio Space: Extending benefits to robotics

Meltio Space brings the same benefits as Meltio Horizon to multi-axis robotic systems. This software offers additional resources for Meltio Robot Integrations, including printing profiles, material datasheets, and verification tools.

Meltio Engine Software Partners Ecosystem

The Meltio Engine Software Partners Ecosystem creates a network of reliable software solutions for customers using Meltio Engine Laser Integration Kits.

Meltio Software Partners

Aplus+Mastercam by Camufacturing and Mastercam | Hypermill by OpenMind | Fusion 360 by Autodesk | SiemensNX by Siemens | AdaOne by Adaxis | AiSync by AiBuild | SKM DCAM by SKM Informatik | Esprit by Hexagon | Hy5CAM by 1ATechnologies | RobotStudio 3D Printing PowerPack by ABB | SprutCAM X by SprutCam

Meltio Engine CNC Integration and Software Partners

The additive software module must be requested from the software reseller, as the machining modules alone are not sufficient to support the Meltio process.