Mold and die making are foundational to global manufacturing, supporting critical industries such as automotive, aerospace, oil & gas, and defense. These components, which shape, stamp, and mold materials into high-precision parts, require complex geometries, robust materials, and increasingly faster turnaround times.

Traditional manufacturing methods often struggle to meet these evolving demands. Metal additive manufacturing (AM), particularly wire-laser Directed Energy Deposition (DED), is emerging as a disruptive solution—reshaping how tool and die shops approach production and repair. Meltio stands at the forefront of this transformation.

1. Tool & Die Shops: Backbone of metal manufacturing

Tool and die shops specialize in the design and manufacture of molds and dies used in mass production. These facilities play a crucial but often overlooked role in shaping the metal parts found in everything from consumer goods to industrial machinery. Depending on the application, tool and die shops may produce:

Cutting & stamping dies: For mass production of cut or bent sheet metal parts.

Drawing dies: For light or deep drawing to create formed parts.

Hot stamping molds: For shaping pre-heated metals in press molds.

Injection molds (plastic or metal): For producing complex components via molten material injection.

Extrusion & blow molds: For shaping continuous profiles or hollow forms like bottles.

2. Conventional limitations in a competitive market

Tool and die shops face mounting pressures:

- Cost & time constraints: Customers demand high-quality parts quickly and affordably.

- Tool wear & waste: Traditional CNC and EDM machining waste expensive material and wear tooling rapidly.

- Complexity & customization: Increasing part complexity and the need for conformal cooling are difficult to address with subtractive manufacturing.

- Repair downtime: Worn or damaged dies can delay production; traditional repair options are limited or slow.

Competitive barriers: Without advanced capabilities, many shops struggle to meet modern manufacturing demands or take on high-value contracts.

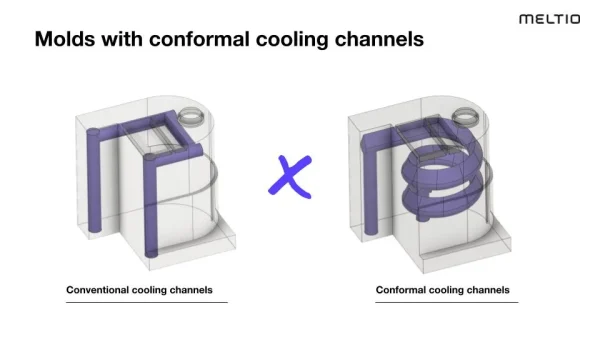

2.1 Challenge 1: Complex geometries & conformal cooling

Problem:

Modern molds require intricate internal channels for optimized cooling. Conventional methods like CNC or EDM can’t create complex, conformal channels, leading to inefficient cycle times and increased wear.

Meltio solution:

Meltio’s wire-laser AM allows layer-by-layer construction of mold inserts with conformal cooling built into the geometry—near the surface, curved, or angled as needed. Copper and steel can be combined to improve thermal conductivity and corrosion resistance.

Result:

80% cycle time reduction in cooling stages

Enhanced product quality via uniform temperature distribution

Reduction in cavity corrosion and parts defect

“Meltio wire-laser metal AM solutions are good for the manufacture of molds. Injection molds, for stamping. One of the first advantages in molds is the wide range of materials we can use. All steels. We can go from steels for plastic injection molds like H11 to high speed or harder steels like an M7 with high hardness used. The other advantage is how the printed material comes out with a great quality, with a very good densification without noticeable pores, we have a high density of the material. Because the material cools quite fast, we have fine microstructures that favors the hardness.”

2.2 Challenge 2: High material costs & tooling wear

Problem:

Traditional mold production wastes expensive tool steels and wears down cutting tools—driving up costs and slowing production.

Meltio solution:

Near-net-shape AM with dual-material capability enables users to build parts with hardened working surfaces (e.g., M7) and cost-effective ductile cores—saving material and extending tooling life.

Result:

Up to 50% material savings

Reduce CNC workload and tooling costs

Increase shop capacity through additive integration

2.3 Challenge 3: Long lead times & downtime from wear

Problem:

Damaged or worn dies often require complete remanufacturing, leading to production delays and excess inventory.

Meltio solution:

Meltio’s DED technology can repair worn areas directly on the part, building back worn edges or features and extending mold life.

Result:

Faster tool refurbishment

Reduced downtime

Extended life for high-wear molds and punches

2.4 Challenge 4: Limited capability with traditional machines

Problem:

Complex parts that combine multiple materials, internal features, or unusual geometries are often unachievable with CNC or casting alone.

Meltio solution:

Wire-laser AM integrated with existing CNC platforms allows tool and die shops to add an additive workflow without replacing their infrastructure.

Result:

Accept new, high-complexity contracts

Streamlined prototyping and customization

Enhanced shop versatibility and ROI

“We provide customers with a closed ecosystem that supports mold manufacturing. We enable the use of up to four different materials in a single mold, offering both performance and cost savings.”

3. The key benefits of Meltio’s Wire-Laser Metal AM for tool & die shops

The benefits of using Meltio technology for this sector are mainly based on the fact that these solutions can manufacture parts with different types of materials at the same time -multi-material with great results of reliability and accuracy-, the solutions work in workshops 24/7, easy to use, parts with complex geometries and easy to learn for the workteam.

Wire-laser metal 3D printing technology stands out as a game-changer in the creation of metal tool and die components. By offering new limits in production speed, installed directly in the die shops, new great possibilities in printed design parts, and material optimization, metal additive manufacturing is reshaping the way manufacturers approach tool and die manufacturing.

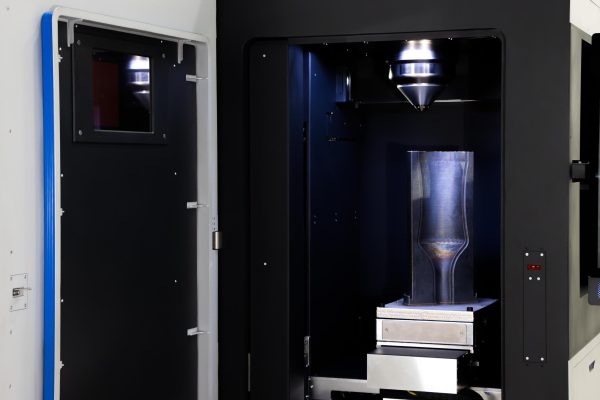

In tool and die manufacturing industrial sectors, this means manufacturers can produce tools with optimized cooling channels, intricate features, and lightweight designs that are crucial for improving the performance and longevity of molds and dies. Meltio metal DED solutions –Meltio M600, and Meltio integration kit for Industrial robots– are the perfect industrial solutions for Tools & Die shops by embedding cooling channels directly within a mold, manufacturers can improve the cooling efficiency, which reduces cycle times and enhances the quality of molded parts.

Other benefits for using Meltio’s solutions for Tool & Die Shops are related with cost and material savings, reducing time to market and fast prototyping and serial spare parts, cost efficiency for low-volume production, improving durability and performance of printed parts (different metal materials such as titanium, copper, aluminum, stainless steel, nickel, and others), and reduced material waste. Dual-material builds (ductile core + hardened surface) reduce material use and repairs worn tools without replacing the complete part. Meltio’s wire-laser metal 3D printing technology. About Productivity gains, the wire DED metal 3D printing is helping this sector in conformal cooling because this one reduce injection mold cycle times by up to 80% and enables higher output with fewer maintenance cycles.

Meltio solutions expand capabilities for complex geometries and multi-material components (are impossible via subtractive methods).

In terms of quality and sustainability these are the main advantages of using wire-laser DED technology:

Sustainable Operations

- Less waste.

- Improved energy efficiency through reduced cycle times and precision cooling.

Enhanced Mold Lifespan & Quality

- Meets high-cycle SPI classifications (101–105).

- Injection molding inserts show uniform cooling, reduced defects, and consistent quality.

4. A future-proof manufacturing strategy

Tool and die shops are at a pivotal point—pressured to evolve by growing demands for complexity, speed, and cost-efficiency. Meltio’s wire-laser metal additive manufacturing technology offers a strategic advantage: transforming legacy operations into agile, high-performance manufacturing hubs. Whether it’s producing conformally cooled molds, repairing high-wear tools, or integrating AM with CNC workflows, Meltio provides a practical, powerful pathway to modernization.

Meltio empowers tool and die makers to manufacture smarter, faster, and with greater precision—turning today’s challenges into tomorrow’s competitive edge.

To know more about tooling and mold making check our webinar HERE