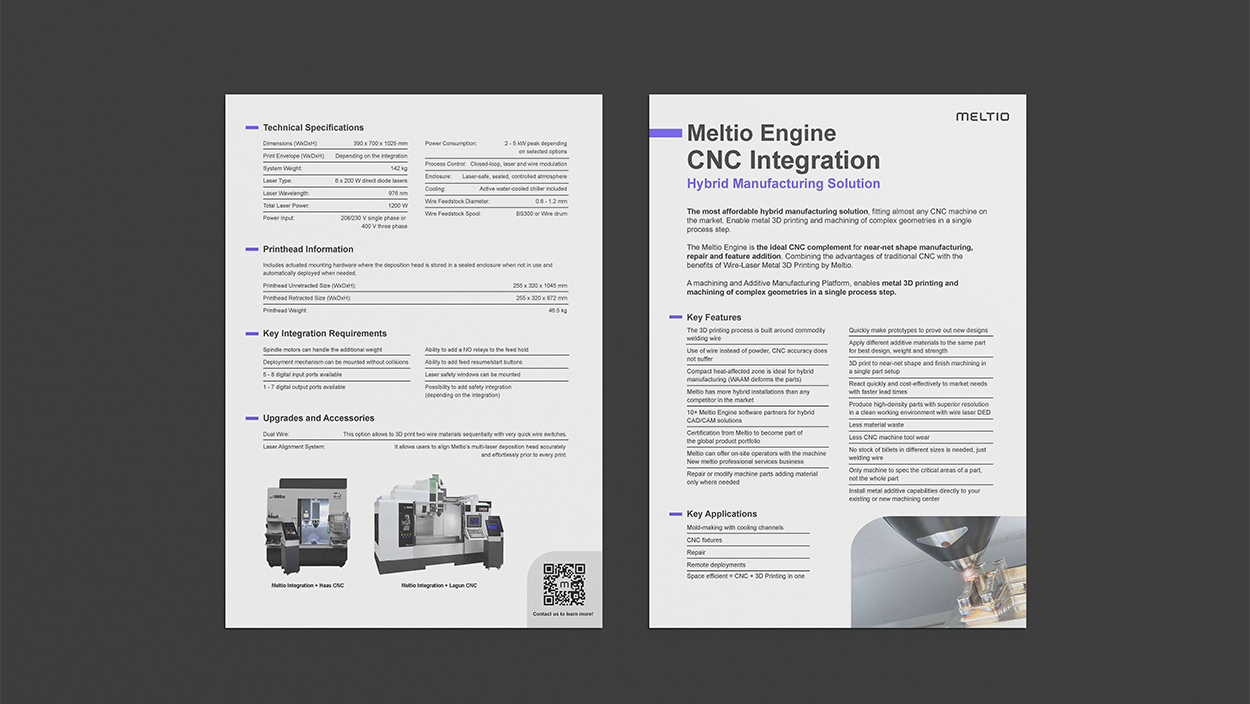

Meltio Engine

CNC Integration

Hybrid Manufacturing Solution

The most affordable hybrid manufacturing solution, fitting almost any CNC machine on the market. Enable metal 3D printing and machining of complex geometries in a single process step.

The Meltio Engine is the ideal CNC complement for near-net shape manufacturing, repair and feature addition.

Machining and Additive Manufacturing Platform

It fits almost any CNC machine. Enables metal 3D printing and machining of complex geometries in a single process step.

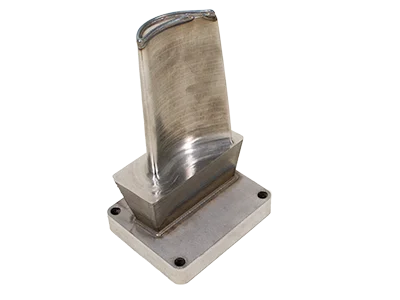

Hybrid Manufacturing

Create highly complex parts with machining tolerances in the same process.

Part Repair

Cost-effective component repair, part augmentation, and feature addition.

Retrofitting

Provide new capability to any CNC machine by turning it into an hybrid metal manufacturing system.

Geometry Freedom

No inherent constraints when the working envelope is only limited by the size of the motion system.

Technical Specifications

Dimensions (WxDxH):

390 x 700 x 1025 mm

Print Envelope (WxDxH):

Depending on the integration

System Weight:

142 kg

Laser Type:

6 x 200 W direct diode lasers

Laser Wavelength:

976 nm

Total Laser Power:

1200 W

Power Input:

208 / 230 V single phase or 400 V three phase

Power Consumption:

2 – 5 kW peak depending on selected options

Process Control:

Closed-loop, laser and wire modulation

Enclosure:

Laser-safe, sealed, controlled atmosphere

Cooling:

Active water-cooled chiller included

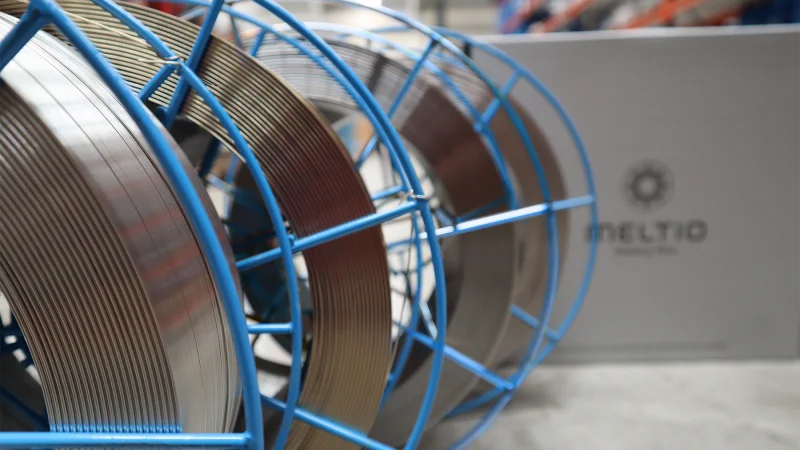

Wire Feedstock Diameter:

0.8 – 1.2 mm

Wire Feedstock Spool:

BS300 or Wire drums

Wire Materials

Stainless Steels:

Excellent strength and corrosion resistance.

Mild Steels:

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels:

High impact strength, retain hardness at high temperatures.

Titanium Alloys:

Highest strength to weight ratio and corrosion resistance.

Nickel Alloys:

High versatility, outstanding heat and corrosion resistance.

Cooper & Aluminum:

Under Development. Let me know when they are available.

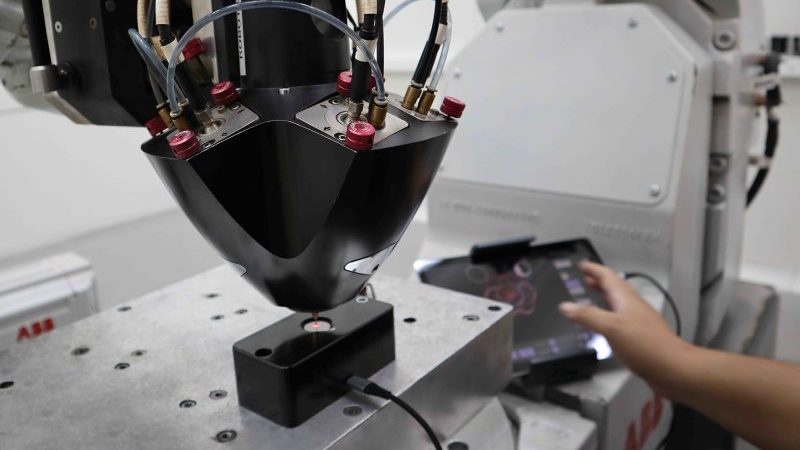

Printhead Information

Includes actuated mounting hardware where the deposition head is stored in a sealed enclosure when not in use and automatically deployed when needed.

Printhead Unretracted Size (WxDxH):

255 x 320 x 1045 mm

Printhead Retracted Size (WxDxH):

255 x 320 x 872 mm

Printhead Weight:

46.5 kg

Key Integration Requirements

Includes actuated mounting hardware where the deposition head is stored in a sealed enclosure when not in use and automatically deployed when needed.

Spindle motors can handle the additional weight.

Deployment mechanism can be mounted without collitions.

5 – 8 digital input ports available.

1 – 7 digital output ports available.

Ability to add a NO relays to the feed hold.

Possibility to add safety integration (depending on the integration).

Laser safety windows can be mounted.

Ability to add feed resume/start buttons.

*The integration will require laser safety windows, door safety interlocks and sheet metal protection for any penetrations in the roof or side walls of the machine. These hardware items are to be sourced by the integrator and depend on the CNC machine of choice.

Upgrades and Accessories

Dual Wire:

This option allows to 3D print two wire materials sequentially with very quick wire switches.

Laser Alignment System:

It allows users to calibrate Meltio’s multi-laser deposition head accurately and effortlessly prior to every print.

Meltio CNC Applications

Watch Bezels

Titanium 64

Size:

50 x 45.9 x 12.7 mm

Weight:

0.25 kg

Print Cost:

$ 40

Elbow

SS316L

Size:

ext. 70 Ø – int. 50 Ø mm

Weight:

0.51 kg

Production Time:

6 h

Gas Turbine Blade Repair

Nickel 625

Size:

65 x 29 x 6 mm

Weight:

0.015 kg

Print Cost:

$ 1.55

Software Partner Ecosystem

Meltio provides an open platform for software that meets a variety of industrial application demands as well as proprietary software tailored to the wire-laser metal 3D printing process which is seamlessly integrated with Meltio’s hardware and material portfolio.

Software Partner Ecosystem

Meltio provides an open platform for software that meets a variety of industrial application demands as well as proprietary software tailored to the wire-laser metal 3D printing process which is seamlessly integrated with Meltio’s hardware and material portfolio.

Wire LMD for the Machine Shop

Join us for an insightful webinar held together with Phillips Corporation to discover cutting-edge advancements in metal 3D printing and its game-changing applications for machine shops.

Meltio Engine CNC

Integration Advantages

What are the advantages of our hybrid manufacturing?

Read this whitepaper to know more about our hybrid integration.

Meltio Engine CNC

Integration Advantages

What are the advantages of our hybrid manufacturing?

Read this whitepaper to know more about our hybrid integration.

Laser Alignment System

The Laser Alignment System is a product developed by Meltio to aid the adoption of our state-of-the-art wire-laser deposition technology as well as to ensure print process reliability, and enhance user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single wire and dual wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single wire and dual wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Metal 3D Printing Experiences

Francesc Martínez

R&D Integrations Director / Sivó

” If we compare with other makers of laser, with Meltio we’ve had the clearer deposition in thousands of parts, and that is nice to see. We can also make some parts that are impossible to make without Meltio’s technology.

We can produce one part with one configuration, then another one with a total different one. Without Meltio’s technology, we wouldn’t be able to do it because the costs would be too high. “

Sivó is a Spanish company specialized in the repair of glass molds using a Meltio Engine CNC Integration.

Get a Quote

Meltio Engine CNC Integration

Receive a tailor-made offer within 1 – 2 business days.