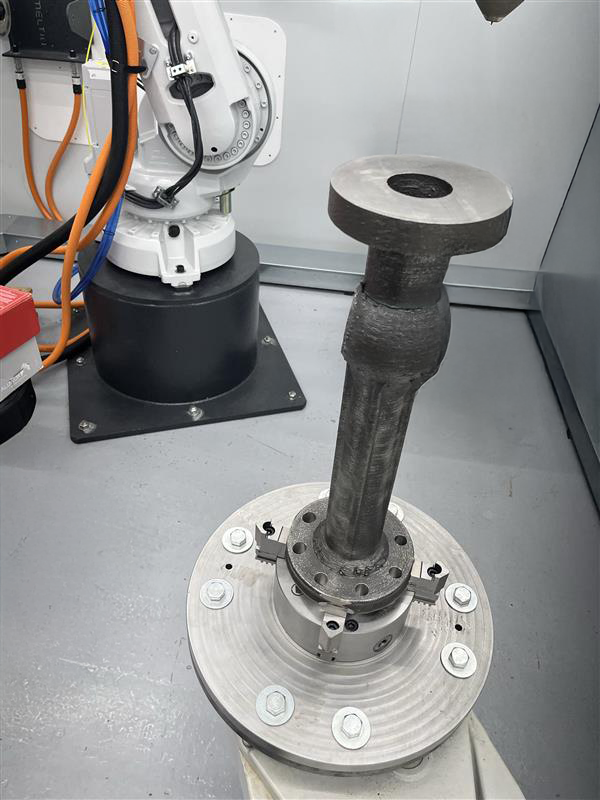

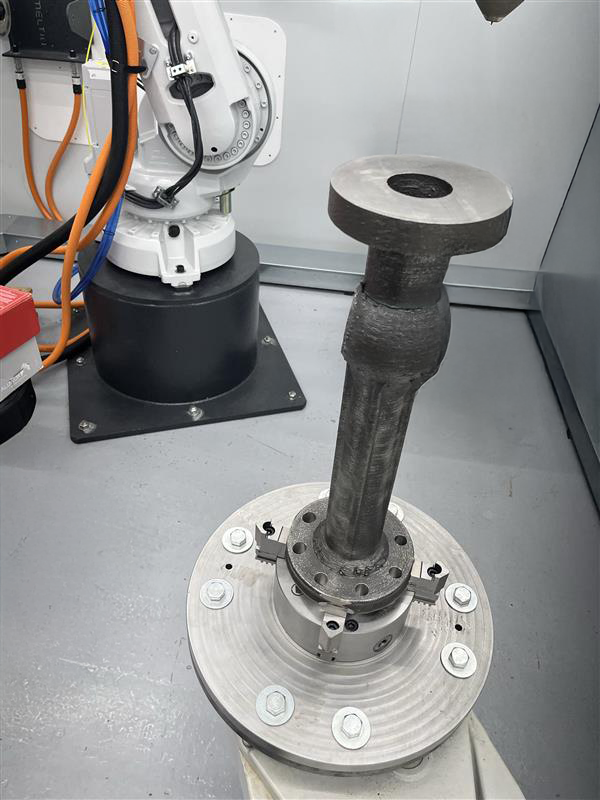

With Meltio, digitally storing designs and manufacturing them on demand is a game-changer for defense readiness. Eductors, despite being niche components, become resilient to supply chain disruptions.

No molds. No waiting. Just functional parts, printed anywhere — from a naval base to a mobile AM unit.