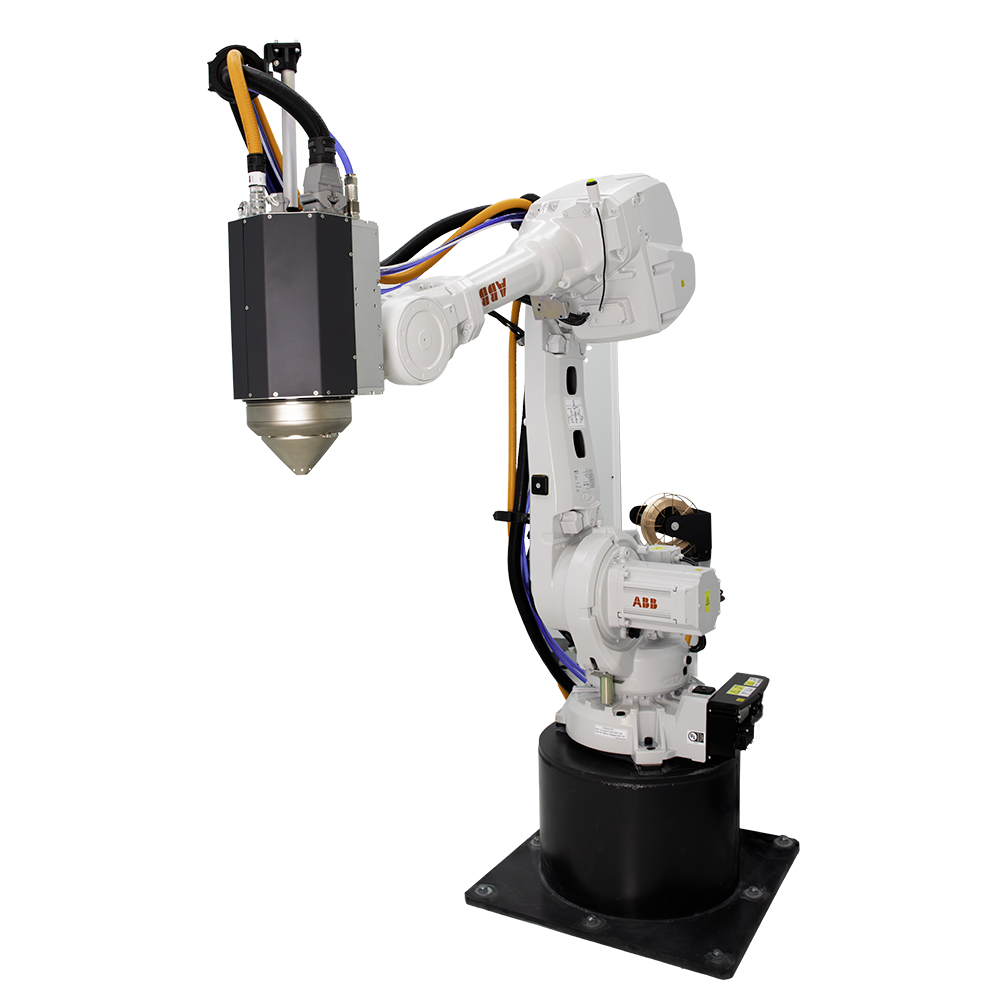

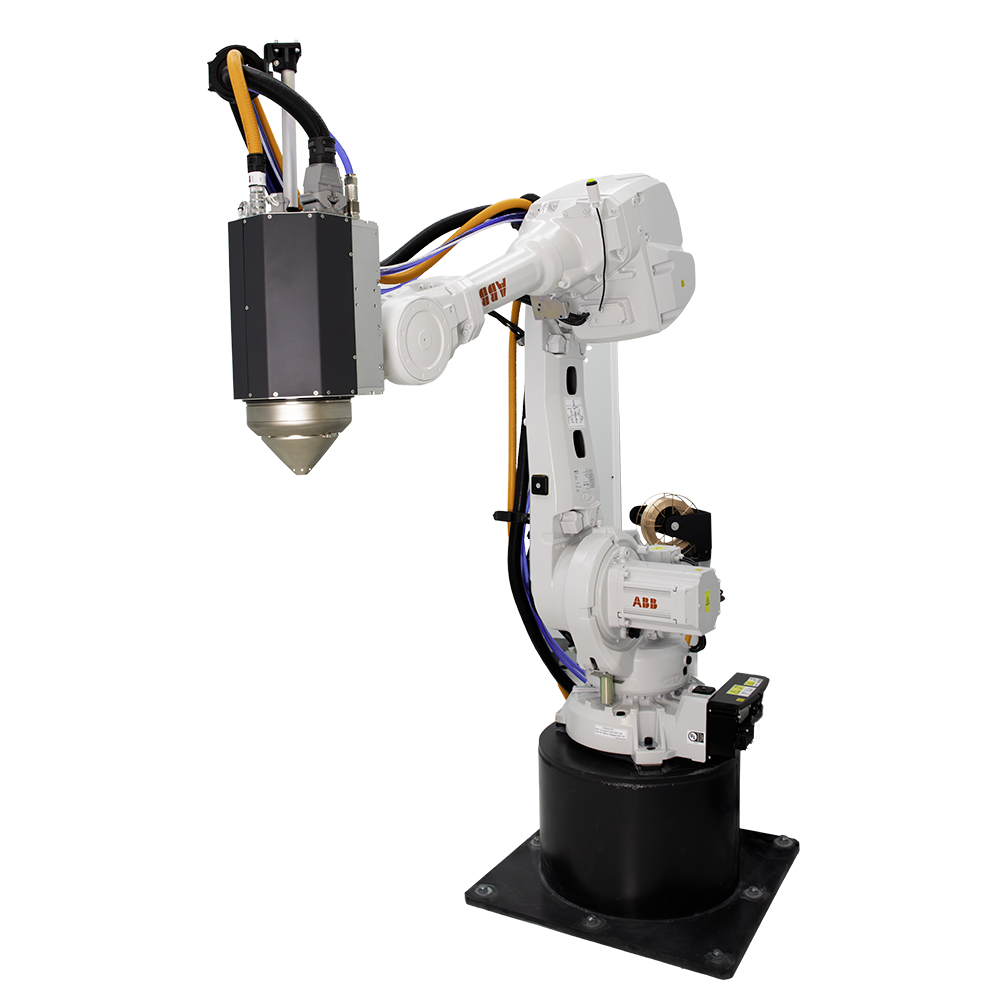

Meltio Engine Integration Kit

for Industrial Robots

Turn a robot arm into a metal 3D printing system with no inherent size constraints. lt is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

The Meltio Engine integrates with any robot arm manufacturer and interface on the market. Meltio Space slicer software for robots is compatible with ABB, Kuka, Fanuc, Yaskawa and Siemens.

Large-Scale Metal 3D Printing

Overcome traditional manufacturing limitations, producing intricate geometries that were previously impossible or too costly to realize.

Large-Scale

No inherent constraints when the working envelope is only limited by the size of the motion system.

Geometry Freedom

Create highly complex parts with infinite degrees of freedom.

Cladding

Provide new capabilities to any robot arm by turning it into a metal 3D printing system.

Part Repair

Technical Specifications

New! Meltio Engine Blue Integration kit

Laser System:

Blue Laser (Higher absorption and power efficiency; wider range of compatible materials than IR)

1000W 9 x 450 nm direct diode lasers

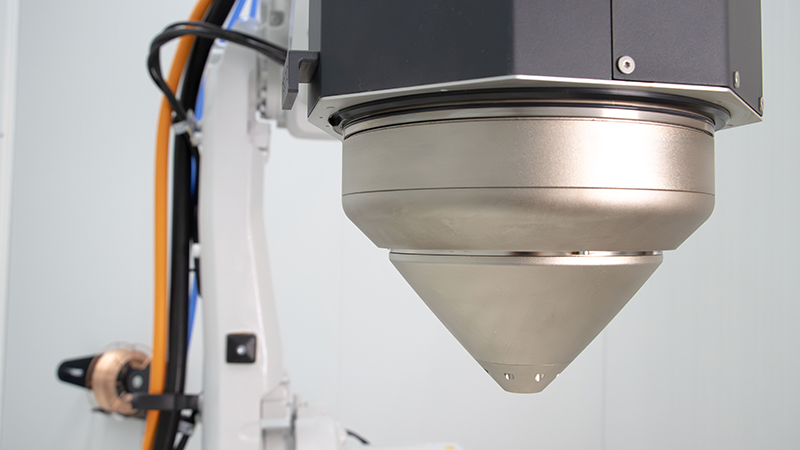

Printhead:

Robot Mounted 20.5 to 23 kg

Printhead Size (WxDxH):

262 x 272 x 572 mm

Control Unit:

Wall mounted, air-cooled 80.5 kg 600 x 300 x 800 mm. Separate wall mounted 27″ HMI

Cooling:

Water-cooled deposition head. Chiller lncluded

Print Envelope (WxDxH):

Depending on robot’s reach

Process Control:

Melt Pool Camera & Closed-loop wire modulation

Power Input:

200/240 V 3W+PE 380/415 V 3W+N+PE

Power Consumption:

9,2 kW peak 2-5 kw avg.

Slicer Software:

Meltio Space 1-year subscription lncluded

Feeder System:

Quad-point traction servomotor feeder, frictionless liners

Wire Feedstock:

Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready

Product Configurations:

Single or Dual Wire

Compatible Materials:

Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium, Copper Alloys, Gold alloys and more

Meltio Engine IR Integration kit

Laser System:

Infrarred Laser

1200W 6 x 976 nm direct diode lasers + fibers & colimators

Printhead:

15.5 kg

Printhead Size (WxDxH):

230 x 310 x 710 mm

Control Unit:

Floor Mounted (Wheeled) 125 kg with 27″ HMI 390 x 650 x 1600 (deployed screen)

Cooling:

Water-cooled control unit and deposition head. Chiller included

Print Envelope (WxDxH):

Depending on robot’s reach

Process Control:

Closed-loop, wire modulation

Power Input:

200/240 V 3W+PE 380/415 V 3W+N+PE

Power Consumption:

2 – 5 kW peak depending on selected options

Slicer Software:

Meltio Space 1-year subscription lncluded

Feeder System:

Dual traction stepper motors + External Feeder (Push-pull system), conventional wire liners

Wire Feedstock:

Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready

Product Configurations:

Single or Dual Wire

Compatible Materials:

Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium and more

New! Meltio Engine Blue Integration kit

General Specifications

Laser System:

Blue Laser (Higher absorption and power efficiency; wider range of compatible materials than IR)

1000W 9 x 450 nm direct diode lasers

Printhead:

Robot Mounted 20.5 to 23 kg

Printhead Size (WxDxH):

262 x 272 x 572 mm

Control Unit:

Wall mounted, air-cooled 80.5 kg 600 x 300 x 800 mm. Separate wall mounted 27″ HMI

Cooling:

Water-cooled deposition head. Chiller lncluded

Print Envelope (WxDxH):

Depending on robot’s reach

Process Control:

Melt Pool Camera & Closed-loop wire modulation

Power Supply

Power Input:

200/240 V 3W+PE 380/415 V 3W+N+PE

Power Consumption:

9,2 kW peak 2-5 kw avg.

Materials and Software

Slicer Software:

Meltio Space 1-year subscription lncluded

Feeder System:

Quad-point traction servomotor feeder, frictionless liners

Wire Feedstock:

Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready

Product Configurations:

Single or Dual Wire

Compatible Materials:

Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium, Copper Alloys, Gold alloys and more

Meltio Engine IR Integration kit

General Specifications

Laser System:

Infrarred Laser

1200W 6 x 976 nm direct diode lasers + fibers & colimators

Printhead:

15.5 kg

Printhead Size (WxDxH):

230 x 310 x 710 mm

Control Unit:

Floor Mounted (Wheeled) 125 kg with 27″ HMI 390 x 650 x 1600 (deployed screen)

Cooling:

Water-cooled control unit and deposition head. Chiller included

Print Envelope (WxDxH):

Depending on robot’s reach

Process Control:

Closed-loop, wire modulation

Power Supply

Power Input:

200/240 V 3W+PE 380/415 V 3W+N+PE

Power Consumption:

2 – 5 kW peak depending on selected options

Materials and Sofware

Slicer Software:

Meltio Space 1-year subscription lncluded

Feeder System:

Dual traction stepper motors + External Feeder (Push-pull system), conventional wire liners

Wire Feedstock:

Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready

Product Configurations:

Single or Dual Wire

Compatible Materials:

Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium and more

Applications

Meltio Engine Integration kit for Industrial Robots

Rotary Screw Compressor

SS316L

Size:

75 x 75 x 230 mm cladded

Weight:

3 kg

Print time:

21h 16′

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

Print time:

21h 23′

Spherical Tank

SS316L

Size:

500 Ø mm

Weight:

30 kg

Print time:

6h 26′

Rotary Screw Compressor

SS316L

Size:

75x 75 x 230 mm cladded

Weight:

3 kg

Print time:

21h 16′

Pipe Manifold

SS316L

Size:

205 x 360 x 473 mm

Weight:

5 kg

Print time:

21h 23′

Spherical tank

SS316L

Size:

500 Ø mm

Weight:

30 kg

Print time:

6h 26′

Meltio Space

This toolpath generator software is specifically developed for accelerated adoption of Meltio technology, revolutionizes the field of robotic additive manufacturing. With its intuitive design, users can quickly adapt to and leverage the benefits of robotic additive manufacturing without requiring expertise in robotics or programming.

Meltio Space

This toolpath generator software is specifically developed for accelerated adoption of Meltio technology, revolutionizes the field of robotic additive manufacturing. With its intuitive design, users can quickly adapt to and leverage the benefits of robotic additive manufacturing without requiring expertise in robotics or programming.

Wire-Laser

DED Applications

Discover Meltio’s Wire-Laser DED applications with our state-of-the-art welding wire-based technology.

Wire-Laser

DED Applications

Discover Meltio’s Wire-Laser DED applications with our state-of-the-art welding wire-based technology.

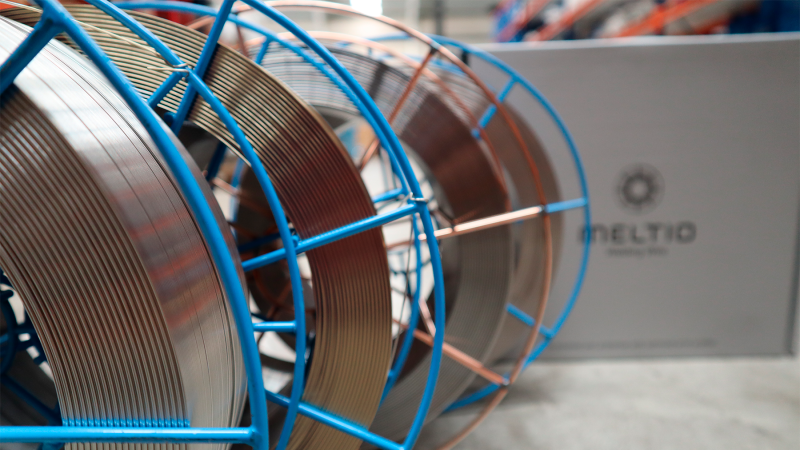

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Meltio Materials

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Metal 3D Printing Experiences

Miguel Peñaranda

Additive Manufacturing Engineer / K3D

” We chose the Meltio product because we found the best balance between high deposition rates and good quality for the task at hand.

Meltio represents for us the right balance between a high deposition speed as well as a high printing size with the best feasible quality or resolution. “

K3D is a Dutch Service Bureau that prints different parts for end-users across various industries using a Meltio M450 and a Meltio Engine Robot Integration.

Get a Quote

Meltio Engine Integration kit for Industrial Robots

Receive a tailor-made offer within 1 – 2 business days.