In industrial metal manufacturing, using a single material often forces a compromise between cost and performance. You might need the corrosion resistance of Inconel but can only afford the cost of Stainless Steel.

Meltio’s Dual Wire technology eliminates this compromise. By feeding two independent wire spools into the same melt pool, our system allows you to switch materials on the fly within a single print job. This opens up applications that are impossible with standard AM systems: cladding, hard-facing, bi-metallic joining, and cost-optimized support structures.

This guide analyzes how Dual Wire works, real-world use cases (like screw compressors), and the material combinations that maximize ROI.

1. Dual Wire: Adding properties where it matters

First, it is worth clarifying in brief what is meant by Dual Wire 3D Printing in Meltio, which enables the printing of two different materials in a single print.

Through this Meltio’s technology, which fulminates the deposited material layer by layer, we have the ability to selectively adjust the properties we are interested in, by modifying the design, preceded by calculations of the forces that support the part. Once we have analyzed the loads and stresses to which the part will be subjected, we derive a design with a series of characteristics that optimize the topology.

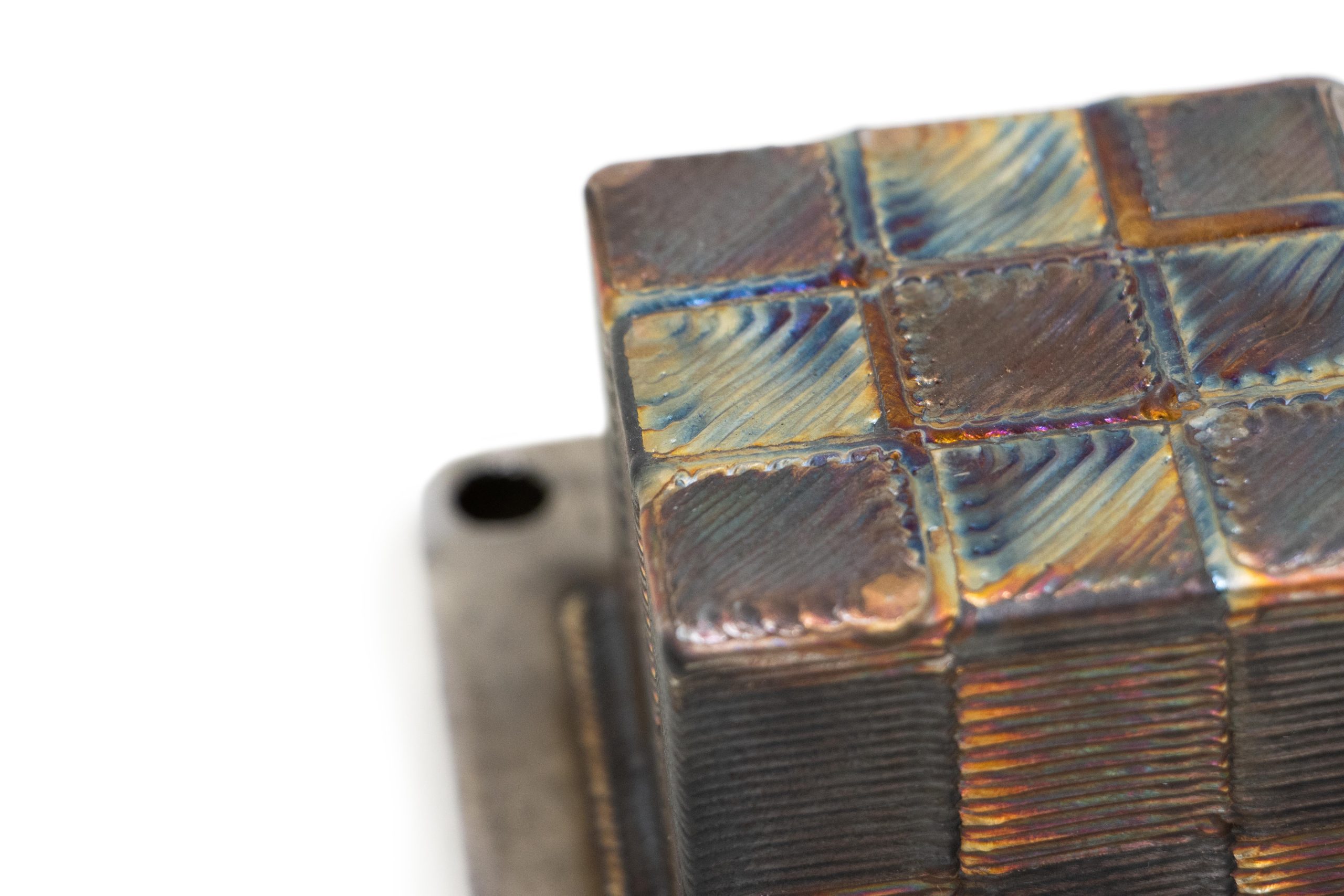

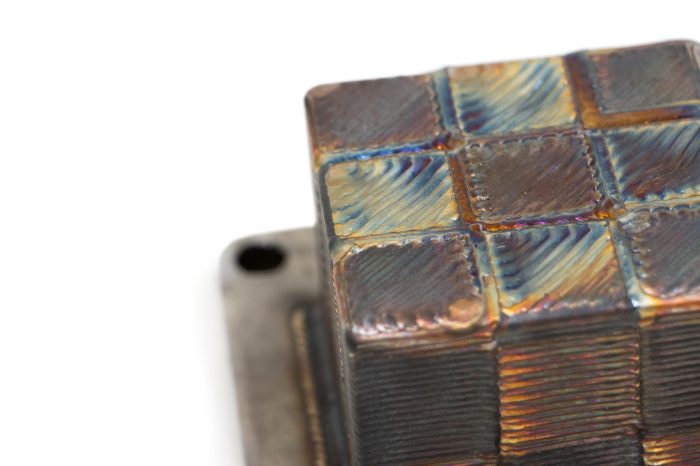

For example, in relation to dual material, we can tell you that a significant number of parts manufactured with Meltio 3D printing have been made using the cladding technique, which could be defined as a technique that covers the sample with a surface layer that coats its geometry with a different material and insulates the sample, giving it new properties.

Our aim with this is to add an outer layer to a part to impart additional properties, as the base part material lacks the necessary characteristics for certain applications. In many cases, these beneficial properties are high hardness, corrosion resistance, or simply to fulfil a reconditioning function. An example to illustrate this would be a construction steel with limited corrosion resistance properties and with our technology, we overlay an additional layer of another material with excellent anti-corrosion properties. In this way, we are able to insulate the material from external corrosion.

2. How dual wire works (And why it's important)

Unlike powder systems that require a complete material changeover, Meltio’s printhead features a quick-switch mechanism. We use two independent wire feeders that can:

Switch sequentially: Print layer 1-10 in Material A, then switch to Material B for the outer shell.

Interlace: Use Material A for the part and Material B for supports.

Grade (future potential): Mix wires to create new alloys in-situ (depending on parameter development).

This capability addresses three main engineering challenges: Surface Wear, Corrosion, and Cost.

3. Key application: Cladding and Hard-Facing

The most immediate industrial application for Dual Wire is Cladding. This involves printing a core geometry using a standard, low-cost material and coating it with a high-performance alloy.

Example: The Anti-Corrosion Pipe

The challenge: A pipeline component needs to resist harsh chemical corrosion (requiring Inconel 625) but must be cost-effective to manufacture.

The Dual Wire Solution:

Core/Structure: Printed in Stainless Steel 316L (Cost-effective, good structural strength).

Internal Liner: Printed in Inconel 625 (High cost, extreme corrosion resistance).

Result: You get the performance of an all-Inconel part at a fraction of the price.

4. Case study: A screw compressor

An example of this is the screw compressor, where cladding has been used to enhance the part. Anyway, we tell you how it is made and how it differs from other traditional manufacturing methods.

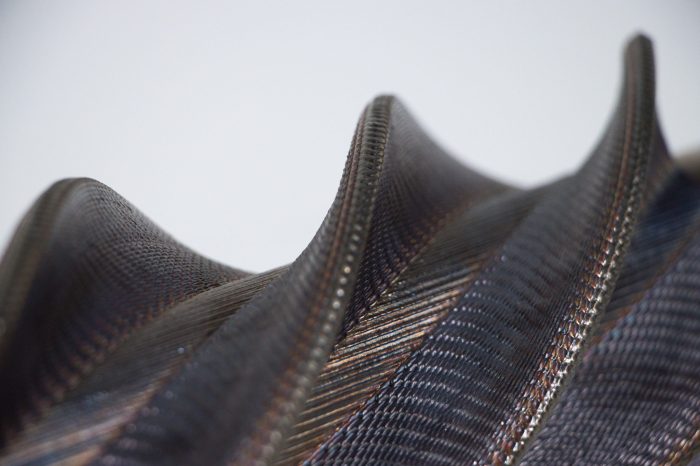

A female steel screw compressor is a type of screw compressor used in various industrial applications such as mining, chemical, petrochemical, food and beverage industries. This compressor is highly efficient and consists of two interlocking screws that rotate in opposite directions inside a casing. One of the screws has a female shape and the other has a male shape, allowing the two screws to move in a rotating action, pushing and compressing the air or gas that is between them towards the compressor outlet.

Female screw compressors are often made of stainless steel due to their high strength and durability and are commonly used for applications that require high-pressure compressed air or gas flow.

Conventional manufacturing methods for screw compressors include cutting, forming, and welding stainless steel sheets to create the compressor housing and parts. CNC machining is also used to create precision parts for the compressor. However, these manufacturing methods are often labor-intensive, expensive, and can generate a significant amount of material waste.

However, by utilizing Meltio technology, the manufacturing process can be significantly improved. Complex geometries and shapes can be produced with customizable designs that cater to specific customer needs. This process allows for faster production runs, reduced manufacturing times, improved product quality, and reduced material waste. Additionally, the process offers the ability to produce unique or limited-edition models while preserving mechanical properties comparable to those produced by traditional manufacturing processes.

Meltio Dual Wire Method:

Body: Printed in ductile Mild Steel or Stainless Steel.

Working surface (Threads): Clad with a wear-resistant Tool Steel or Nickel alloy.

Outcome: A functionally graded part where expensive material is placed only where it interacts with the gas, significantly reducing material costs while extending service life.

5. Design Guidelines for Dual Wire

On many occasions, the optimisation of a part is sought; however, it is important to note that not all parts are susceptible to optimisation, nor is it in all cases of interest to optimize them.

Therefore, in the process of creating a part, depending on the type of part, topological optimisation is often required before printing, ultimately seeking to reduce its structural weight while preserving the fundamental mechanical characteristics of that specific part, without affecting performance or efficiency under significant loads.

Through Meltio technology, we have seen advantages. To begin with, once we receive topological optimization, these designs are often complex because they have geometries and angles that are difficult to manufacture not only by traditional methods, but also by 3D printing technologies themselves.

At Meltio, once we receive the optimized part, we use our Design Guidelines to ensure that we can obtain the best quality when manufacturing it. An example of this could be reducing part angles to improve the printability of the part, or, for example, modifying parameters to achieve lower roughness, without necessarily resorting to machining or minimizing the need for machining.

TIP: Find the Meltio Design Guidelines HERE.

6. Solving material incompatibility: The interlayer technique

Joining two different metals (e.g., Titanium and Steel) usually results in immediate cracking due to the formation of brittle intermetallic compounds. Welding them directly is chemically impossible.

Meltio Dual Wire solves this using Interlayers.

Real-World Lab Test: We successfully bonded a Stainless Steel 304L base to a Titanium 64 top section.

The trick: We printed a transition layer of Silicon Bronze between them.

Why it works: Silicon Bronze bonds well with both Steel and Titanium without creating the brittle phases that cause cracks.

Application: Useful for aerospace components requiring a heavy, strong steel mounting point transitioning to a lightweight titanium body.

7. Cost optimization: Multi-material supports

In standard 3D printing, you often use the same expensive material for the part and the supports. With Dual Wire, you can optimize this:

Part Material: High-value alloy (e.g., Titanium, Inconel).

Support/Raft Material: Lower-cost compatible alloy (e.g., Stainless Steel).

Benefit: Since supports are machined off and discarded, using a cheaper wire for them directly lowers the "cost per part."

9. Additional advantages of using Dual Wire

- Different alloys

Many parts produced using Meltio technology can incorporate high-cost, cobalt- and nickel-based alloys, which provide extra functionalities to the parts, such as could be improved mechanical properties. At Meltio, we have tested different combinations of materials, thus providing different properties to those of their base metals, such as greater resistance to corrosion, wear, etc.

- Versatility

When we talk about versatility, we can refer to the versatility of our technology and its applications. For example, versatility could refer to the ease of changing from one material to another, the fact that parameters can be easily modified with the use of the specific software offered by Meltio to take the user experience to other levels, the wide range of materials offered by Meltio, among numerous other advantages known to anyone who uses our technology:

Different metallic properties to the same part

This capability allows for applications such as hard-facing or anti-corrosion coatings. It offers an easy, fast, convenient, and sustainable solution for multi-material 3D printing, without the risk of cross-contamination of the feedstock.

High-strength components in specific sections

While other areas can benefit from materials with improved thermal conductivity. In short, a material selective approach is used to enhance the functionality of specific areas of the part.

Manufacture complex geometries

These parts, intended for a variety of industrial applications, can adopt solid or hollow configurations, with one or two perimeters, providing flexibility according to the user’s preferences.

In terms of parts and final quality, parts manufactured with Meltio have more than 99.9% density. This high level of density guarantees the uniformity of the material throughout the part, eliminating any possibility of areas prone to breakage. In addition, problems such as lack of fusion are avoided and defects due to fatigue or tensile stresses are minimized, contributing to the integrity and durability of the final product.

10. Conclusion

In summary, Meltio technology offers a number of outstanding advantages, such as the ability to deposit material on pre-existing parts, high density, efficient deposition rate, large build volume, cost-effectiveness, almost unlimited part geometries, versatility in material choice and significantly reduced thermal distortion. The resulting parts can therefore be adapted to a variety of applications and uses due to the diverse mechanical properties that can be achieved.

Frequently Asked Questions

Currently, the system is optimized for sequential switching (rapidly changing from Wire A to Wire B) or creating distinct zones. While mixing to create custom alloys in the melt pool is theoretically possible (in-situ alloying), the primary industrial use case is distinct multi-material zones like cladding or supports.

Dilution Control. Meltio’s laser process has a very low dilution rate. This means the high-performance cladding layer doesn't mix excessively with the base metal, preserving the purity and properties of the expensive alloy even in the first few layers.

Compatibility depends on metallurgy (thermal expansion and melting points). Common successful combinations include:

Stainless Steel + Tool Steel (Hard-facing)

Stainless Steel + Inconel (Corrosion resistance)

Mild Steel + Stainless Steel (Aesthetic/Surface protection)

Steel + Titanium (ONLY with a Silicon Bronze interlayer)

The switch time between wires is negligible. The overall print speed remains comparable to single-wire printing, but you gain significant time savings in post-processing by avoiding complex assembly or manual welding steps.

Yes, Dual Wire technology is available across our integration systems. The Meltio M600 specifically is designed with this capability in mind for industrial production environments.