Hybrid Manufacturing: why Meltio integrates additive and substractive manufacturing

In real manufacturing environments, parts are rarely defined by a single process. Machining, heat treatment, finishing, and inspection are already deeply embedded in production workflows. For metal additive manufacturing to become truly industrial, it must integrate seamlessly into this reality rather than attempt to replace it.

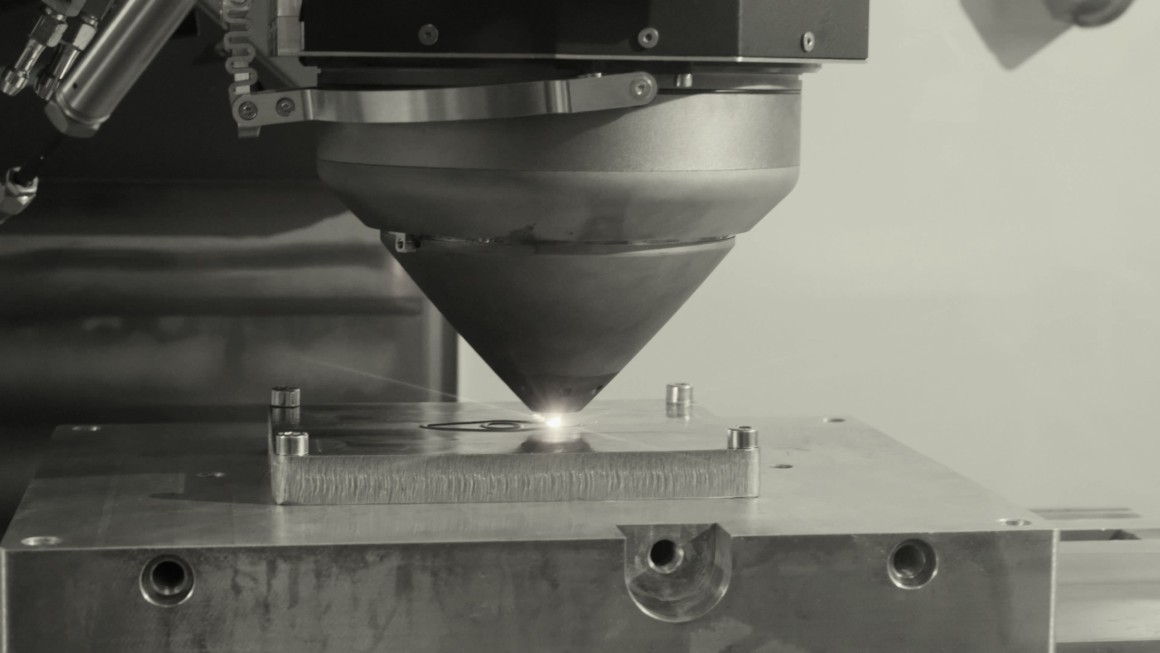

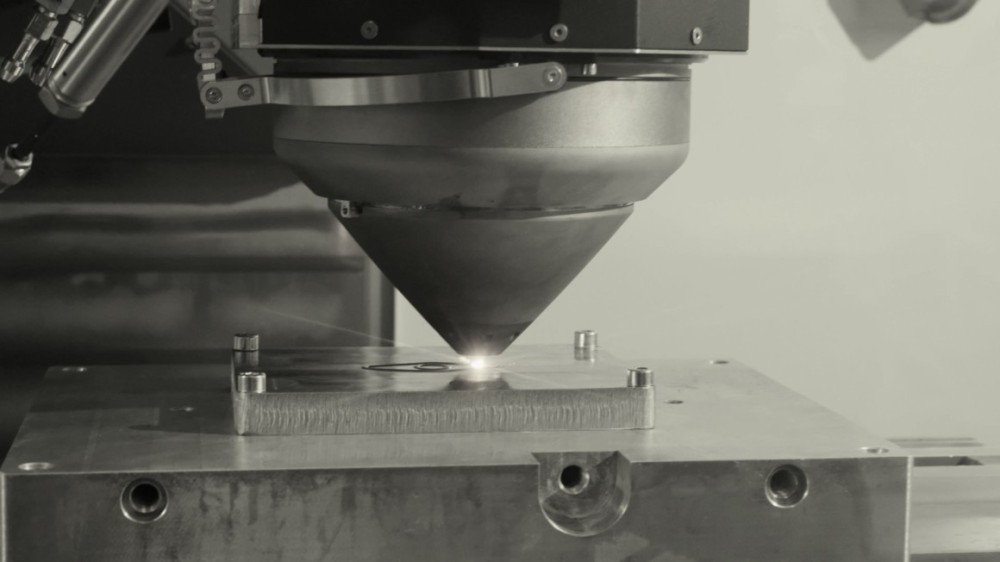

This is the context in which hybrid manufacturing—the combination of additive and subtractive processes within a single system or workflow—becomes not just attractive, but necessary. Meltio’s hybrid CNC + Wire Laser DED configuration exists precisely to address this need: to merge the design freedom and material efficiency of additive manufacturing with the precision, surface quality, and dimensional control of CNC machining.

That’s where Meltio steps in.

By harnessing the power of wire-laser metal additive manufacturing, Meltio’s technology is transforming how the defense industry approaches maintenance, repair, and production of essential components — delivering solutions that are faster, smarter, and built for resilience.

1. The Meltio hybrid approach: additive where it adds value, machining where it matters

Meltio’s hybrid strategy is based on a simple but powerful principle: Use additive manufacturing only where it provides clear value, and rely on machining where precision and surface finish are critical.

In a Meltio hybrid system, the same machine—or tightly integrated workflow—can alternate between:

- Wire Laser DED deposition, adding material layer by layer exactly where needed

- CNC machining, removing material to achieve final tolerances, surface finish, and functional interfaces

This allows parts to be built incrementally: material is deposited, machined, inspected, and then further built upon if required. Rather than printing a full part and machining everything afterward, hybrid manufacturing enables process-aware sequencing, reducing waste, distortion, and unnecessary machining time.

TIP: If you are looking for the technical specifications of how we retrofit a CNC machine read our Technical Guide to CNC Integration.

2. Why this configuration exists: addressing the limits of standalone additive manufacturing

Standalone additive manufacturing systems—whether powder bed or DED—inevitably face trade-offs. Additive excels at creating volume efficiently and enabling complex internal or external features, but it is not inherently optimized for:

Tight dimensional tolerances

Fine surface finishes

Functional mating surfaces

Datum control across large parts

In contrast, CNC machining excels in exactly those areas, but becomes inefficient or impractical when large volumes of material must be removed, or when complex geometries require multiple setups and long machining cycles.

Meltio’s hybrid configuration exists to eliminate the false choice between additive and subtractive. By integrating Wire Laser DED into CNC environments, Meltio enables manufacturers to:

Start from a near-net-shape additive build

Machine only critical surfaces and features

Avoid machining large volumes of unnecessary material

Reduce lead times and material waste compared to machining from billet

This approach directly addresses the economic and practical barriers that often limit the adoption of metal AM in production.

3. Why Meltio Wire Laser DED is particularly suited to hybrid manufacturing

Not all additive technologies integrate equally well with CNC machining. Meltio’s Laser-Wire DED offers specific advantages that make it especially compatible with hybrid configurations.

-

-

Wire feedstock

Provides a clean, controlled material input. Unlike powder-based systems, there is no loose material to contaminate machine components, linear guides, or spindle assemblies. This makes it feasible to integrate additive deposition into CNC platforms without compromising machine reliability or maintenance requirements.

-

Laser-based energy input

Enables localized and controllable heat application. Compared with arc-based wire processes, the laser produces smaller melt pools and lower overall heat input, reducing distortion and making intermediate machining steps more predictable.

-

Meltio’s process control philosophy

Based on energy density, geometry awareness, and real-time monitoring—aligns well with CNC logic. Toolpaths, layer strategies, and deposition parameters can be coordinated with machining operations in a way that supports dimensional accuracy and repeatability.

-

Meltio’s open material platform and qualification methodology

Ensure that the deposited material behaves consistently during machining, reducing uncertainty in tool wear, cutting forces, and surface finish.

-

4. When hybrid CNC + Meltio is the right choice

Hybrid manufacturing is not always necessary, and Meltio does not position it as a universal solution. It is the right approach when additive and subtractive processes each solve a different part of the problem.

Typical scenarios where Meltio hybrid systems deliver the most value include:

Tooling and molds

Where conformal features, repairs, or reinforcements are added additively, while functional surfaces are machined to tolerance

Large or complex components,

Where near-net-shape additive manufacturing drastically reduces machining time compared to starting from billet

Repair and remanufacturing

Where worn or damaged areas are rebuilt additively and then machined back to specification

High-value components

Where minimizing material waste and lead time has a direct economic impact

Low-volume or customized parts

Where flexibility and rapid iteration are critical, but final accuracy cannot be compromised

In these cases, hybrid manufacturing enables manufacturers to combine speed, flexibility, and precision in a single workflow, rather than forcing compromises.

5. Hybrid as a bridge between additive and traditional manufacturing

Perhaps the most important role of Meltio’s hybrid CNC + Wire Laser DED configuration is strategic rather than technical. The strategic advantage of Hybrid is consolidation. Instead of moving a part from a welder to a stress-relief oven to a mill, waiting days between each step, Meltio allows you to consolidate these steps. You are not just buying a printer; you are buying a way to reduce Work-In-Progress (WIP) by 80%.

It acts as a bridge between traditional manufacturing and additive manufacturing, lowering the barrier to adoption.

For organizations already invested in CNC machining, hybrid systems allow additive manufacturing to be introduced incrementally, using familiar machines, processes, and quality frameworks. Operators, programmers, and quality teams can adopt additive capabilities without abandoning established workflows.

This makes Meltio hybrid manufacturing not just a technical solution but a transition strategy, one that allows companies to modernize their manufacturing capabilities while maintaining control, predictability, and confidence.

Don't think of it as 'printing a whole part.' Think of it as Adding Value.

-

Reaction vs. Creation: Don't just print prototypes. Repair a $5,000 mold shaft that would otherwise be scrapped.

-

Features: Add a cooling jacket to an existing cylinder. This is where the ROI lives: saving high-value assets.

6. A pragmatic path to industrial additive manufacturing

Meltio’s hybrid CNC + Wire Laser DED approach reflects a broader philosophy: metal additive manufacturing should adapt to manufacturing, not the other way around.

By integrating additive deposition directly into CNC environments, Meltio enables manufacturers to deploy additive manufacturing where it makes sense, retain machining where it is essential, and combine both into a coherent, production-ready process.

For companies seeking to move beyond isolated additive experiments and toward real industrial impact, Meltio’s hybrid approach represents a practical, scalable, and economically sound path forward

FAQs

We define hybrid manufacturing as the concurrent use of additive and subtractive processes within a single coordinate system. It is not merely placing a 3D printer next to a CNC mill; it is a unified workflow where the Meltio Engine deposits material (Wire-Laser DED) to near-net shape, and the CNC immediately machines it to final tolerance. This approach allows engineers to use additive manufacturing only where it adds geometric value and machining only where precision is critical, effectively eliminating the trade-off between design freedom and dimensional accuracy.

Standalone systems (SLM or separate DED cells) often require complex part transfer, re-referencing (finding the zero point again), and significant post-processing. By integrating the Meltio Engine into a CNC:

Datum consistency is maintained: You machine the part without ever unclamping it, ensuring perfect alignment between printed and machined features.

Immediate surface finishing: You can machine internal channels or complex geometries during the build process (inter-layer machining), which would be impossible to access after the part is fully printed.

Capital efficiency: You leverage existing motion systems (Haas, Mazak, etc.) rather than purchasing a redundant gantry.

Precision and heat input. WAAM (Wire Arc Additive Manufacturing) uses an electric arc (plasma), resulting in high heat input, significant thermal distortion, and lower resolution layers (2-3mm). Meltio uses concentrated laser energy. This results in a much smaller Heat Affected Zone (HAZ), higher cooling rates, and finer layer resolution (0.8mm - 1.2mm). Consequently, Meltio parts require significantly less post-processing time to remove the "scalloped" surface finish typical of arc welding.

The impact is drastic. In traditional subtractive manufacturing, you might start with a 100kg billet to produce a 10kg part (a 90% buy-to-fly ratio). With Meltio’s hybrid approach, you print a near-net shape that is perhaps 10.5kg and machine away only 0.5kg. We frequently document material cost reductions of 40% to 60% for high-value alloys like Inconel 718 or Titanium 64, simply by eliminating the volume of chips generated.

Repair is a primary use case. Because the Meltio Engine mounts directly onto the CNC spindle or head, you can load a worn shaft, mold, or turbine blade, probe the surface to generate a digital twin, and deposit material locally to restore the geometry. The CNC then machines the repair flush with the original surface. This capability extends the service life of tooling and heavy machinery components that would otherwise be scrapped.

Meltio uses standard industrial welding wire (MIG wire). This material is already certified for industrial use, widely available, and significantly cheaper than atomized AM powder (often 10x lower cost/kg). From a metallurgical standpoint, the resulting parts exhibit full density (99.99%) and isotropic mechanical properties comparable to cast or forged metal, provided the correct shielding gas and process parameters are applied.

No. Unlike powder-based systems which pose explosion risks and abrasive damage to ways and ball screws, wire-laser DED is a clean process. The material is fully melted into the bead. There is no airborne powder to contaminate the CNC’s sensitive electronics or seals. The system includes laser safety interlocks and integration protocols that adhere to industrial safety standards (Class 1 laser enclosure requirements).

The transition is seamless because the workflow remains CNC-centric. The Meltio Engine is controlled via standard M-codes within the CNC program. A machinist does not need to learn complex new physics; they simply treat the "printing" pass as a new tool path. We utilize slice software that generates standard G-code, making the additive operation just another step in the familiar CAM workflow.