DPR AUTOMATISMOS, a company of José Antonio Labandeira, was founded in January 2003 with the intention of providing full service to customers at automation level. It specializes in the integration of metal additive manufacturing solutions, specifically, they are official integrators of Meltio technology, focusing on the implementation of the Meltio Engine integration with robotic systems.

Their expertise is focused on adapting and optimizing this technology for various industrial applications.

Virtually any industry that needs to improve and optimize its processes through automation is likely to be their client. To date, they have carried out projects for sectors such as automotive, food products, chemical industry, construction sector, wine sector… and they are prepared to be very versatile and able to face any challenge.

Why Meltio’s DED was the key enabler

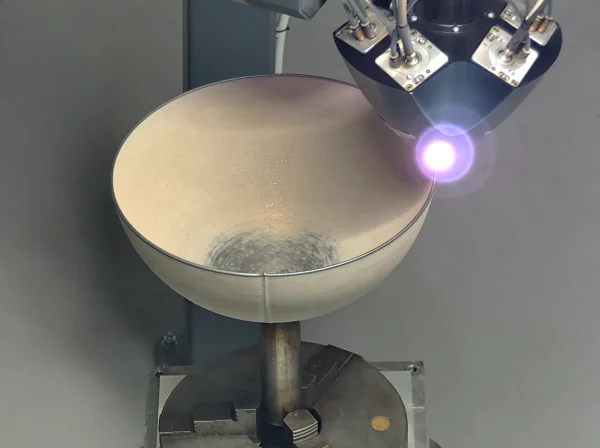

DPR chose Meltio’s laser metal 3D printing solutions because of their versatility and ability to integrate with robotic systems. Laser metal deposition technology offers excellent value for money, material flexibility and the ability to create complex parts with high precision.

In addition, the ability to integrate the Meltio Engine into robotic systems allows them to explore new applications and optimize our manufacturing processes.

In the projects they are developing in collaboration with Meltio and Sicnova, 3D printing is starting to play an important role and will continue to do so, as they believe this technology has and will have a strong impact on all sectors. It is maturing very quickly, so it must be taken into account.

Turning urgent industry needs into engineering innovation

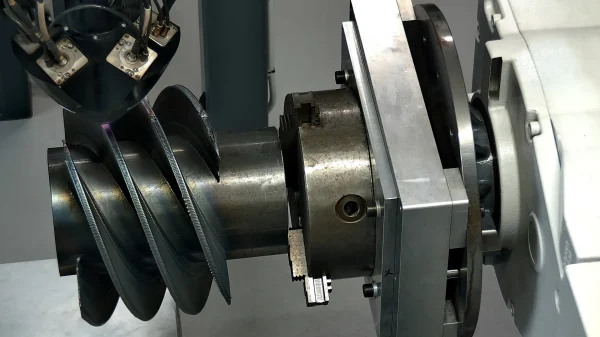

The integration of Meltio’s technology and the Robot arm is replacing traditional processes and transforming industrial processes, enabling on-site manufacturing and repair of large and complex parts. This significantly reduces downtime and transportation costs and advance designs that were previously unmachinable.

“It means offering our customers more efficient and profitable manufacturing solutions not only in economic cost but also in delivery times.“

Advanced robotic metal 3D printing solutions

DPR’s collaboration with Meltio goes beyond simple integration. They are actively involved in the development of innovative solutions. For example, they are constantly collaborating on the development of the self-supporting cell, which enables greater flexibility and mobility in the manufacture of parts.

They are also working on the inertized cell, which enables the manufacture of parts with oxygen-sensitive materials, thus expanding the range of applications of Meltio’s technology.

“A customer needed a spare part urgently, and could not find it in stock at any of its suppliers. These suppliers did not have the parts manufactured and the delivery time was 8-10 weeks.

The printing was done by enlarging the part by 1mm. in order to be able to carry out a machining post-processing. From the delivery of the drawing to the shipment of the part 72 hours.”

Opening the door to new mold design standards

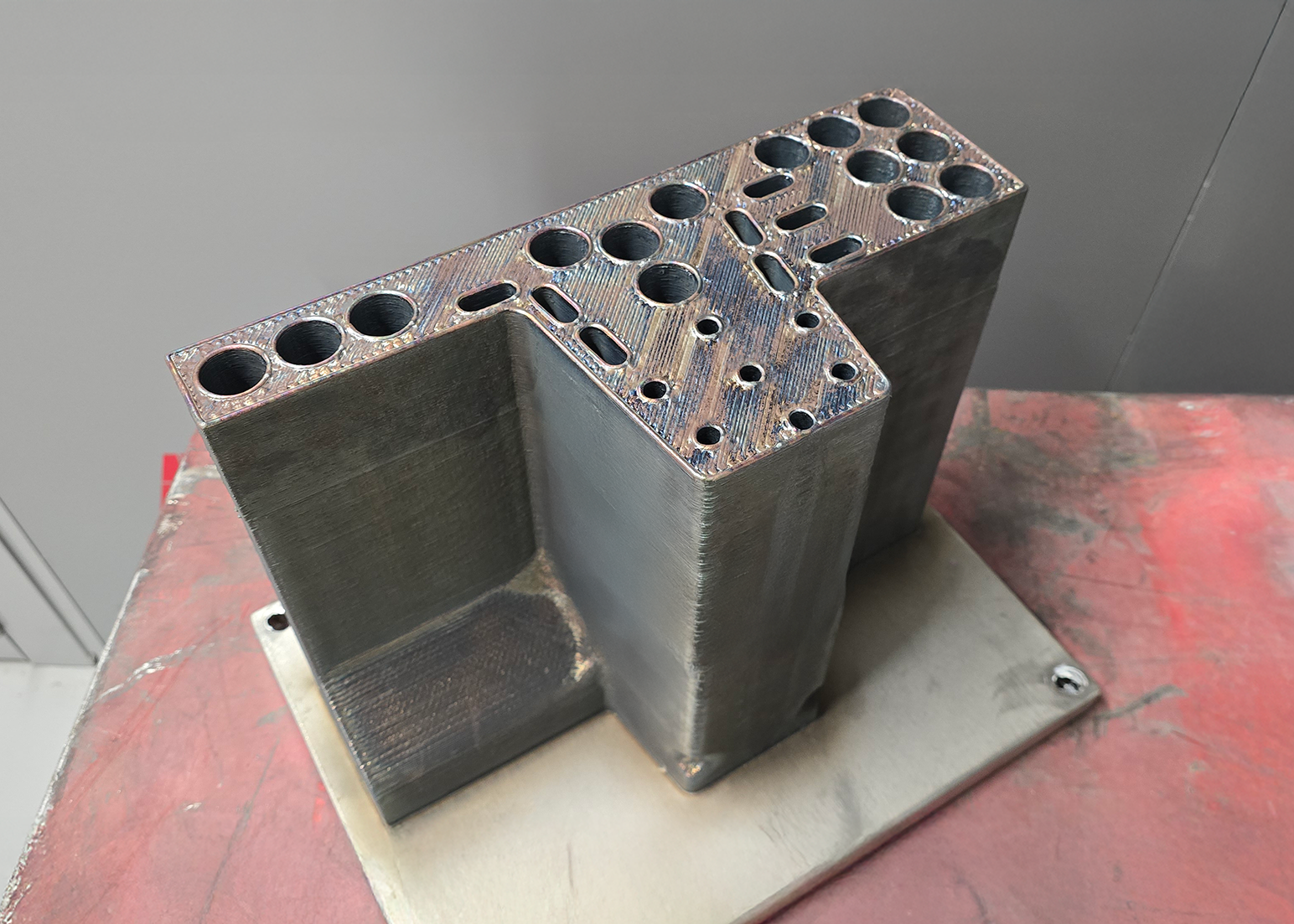

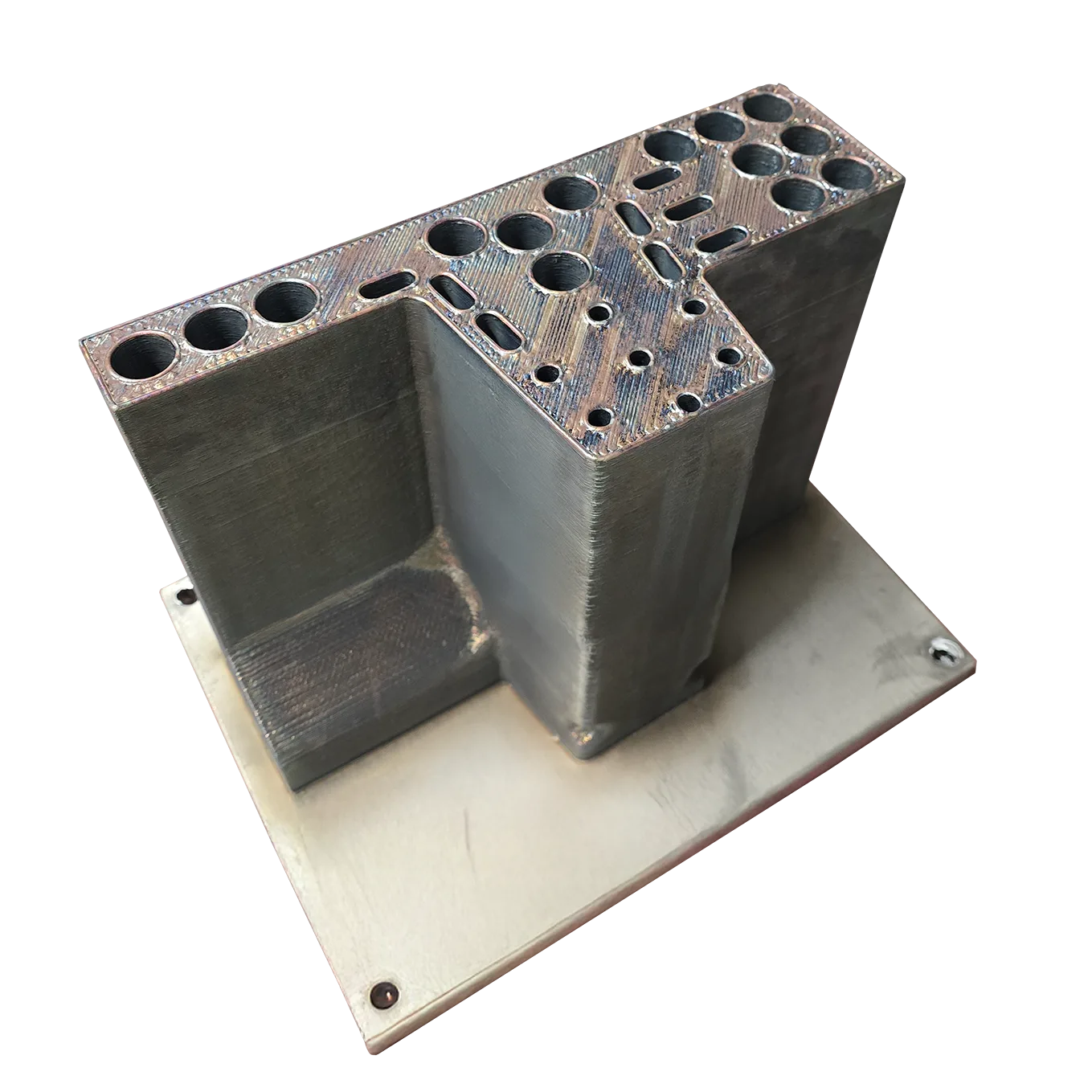

A new project that DPR Automatismos is carrying out consists of the design and additive manufacturing of cooling system test pieces and inserts in molds and dies, as they are crucial components in the manufacturing process, especially in plastic injection and metal casting.

Their main function is to control the mold temperature during the production process, which influences the quality of the final product, the efficiency of the process and the useful life of the mold.

With additive printing, they can make cooling systems that were previously impossible due to their geometries.

The manufacture of mold inserts for hot stamping, using traditional methods, involved long production times and high costs due to the machining and adjustment processes required.

These traditional processes also generated high material waste and limitations in the geometry of the inserts. Their forecasts are:

To reduce the manufacturing time by more than 60%, which will speed up production cycles.

Greater flexibility in the design will be achieved, allowing the hot stamping process to be optimized.

Greater flexibility in the design will be achieved, allowing the hot stamping process to be optimized.

In the process of testing whether it will increase the lifetimes of the inserts.

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

Turn a robot arm into a metal 3D printing system with no inherent size constraints. lt is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

Wire feedstock proves more affordable and safer than powder-based alternatives.

Validated performance and scalable opportunity

As integrators of the Meltio Engine Integration for Robotic arms, DPR’s main interests and expectations in the short and medium term with Meltio are focused on expanding and optimizing the capabilities of this technology to meet the growing demands of the industry.

They believe that these solutions have great potential to transform industrial manufacturing, and they want to continue to contribute to their refinement and commercialization.

DRP also aims to develop customized, turnkey solutions for customers with specific needs, tailoring Meltio + Robot technology to their production processes and quality requirements. This involves creating solutions tailored to each customer’s part dimensions, materials and working environments.

In summary, DPR wants to contribute to the advancement of metal additive manufacturing by developing innovative solutions that drive the transformation of the industry.