Use Cases

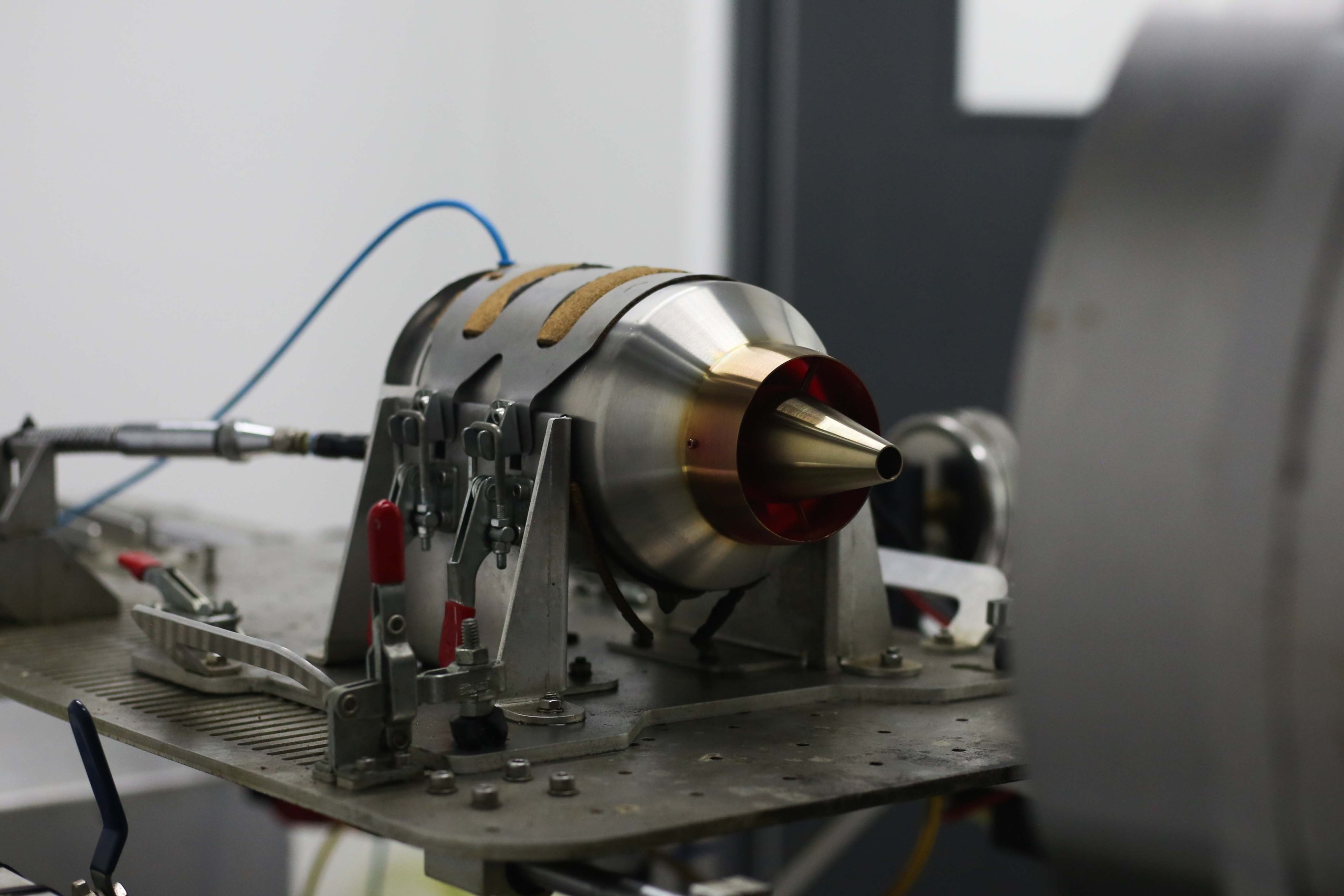

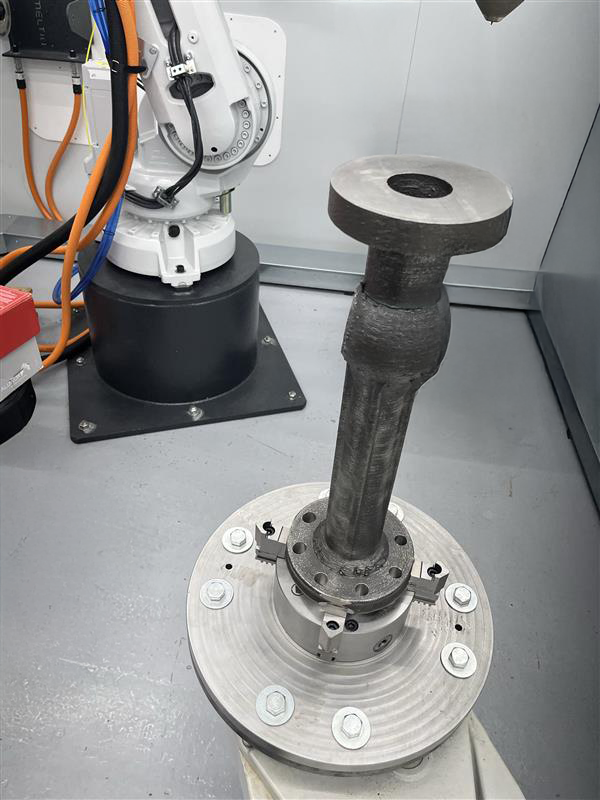

Localized production of critical aerospace components

How HH Industries used Meltio’s hybrid wire-laser AM to localize production of turbine jet engine housings.

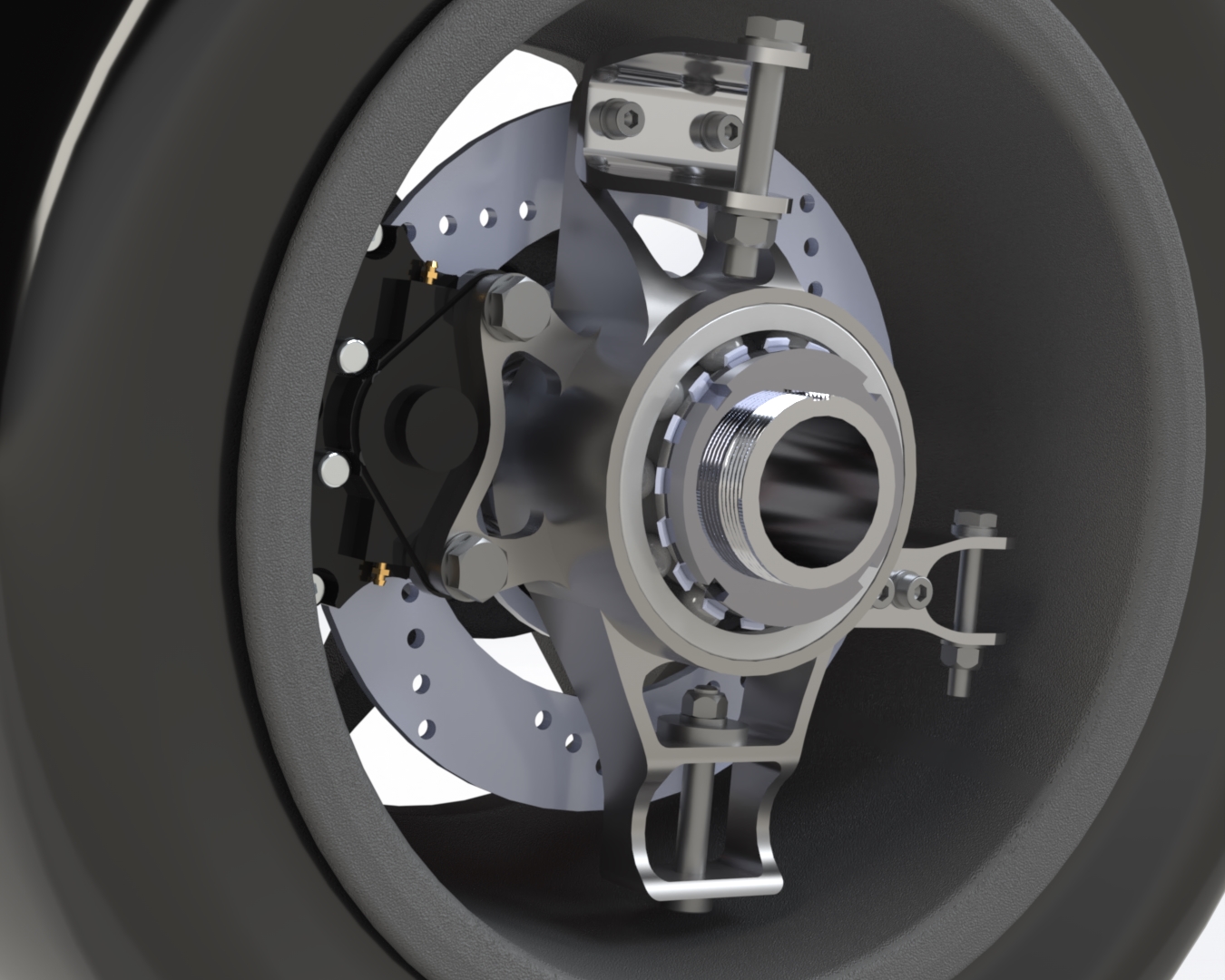

Manufacturing 35% lighter titanium uprights for Formula Student

In Formula Student, engineering compromises are not an optio...

Aerospace innovation with advanced additive manufacturing

Use case developed by CATEC

Meltio continues to take meta...

South Korea’s Defense sector benefits from 60% lighter components

This case study between AM Solutions and the South Korean de...

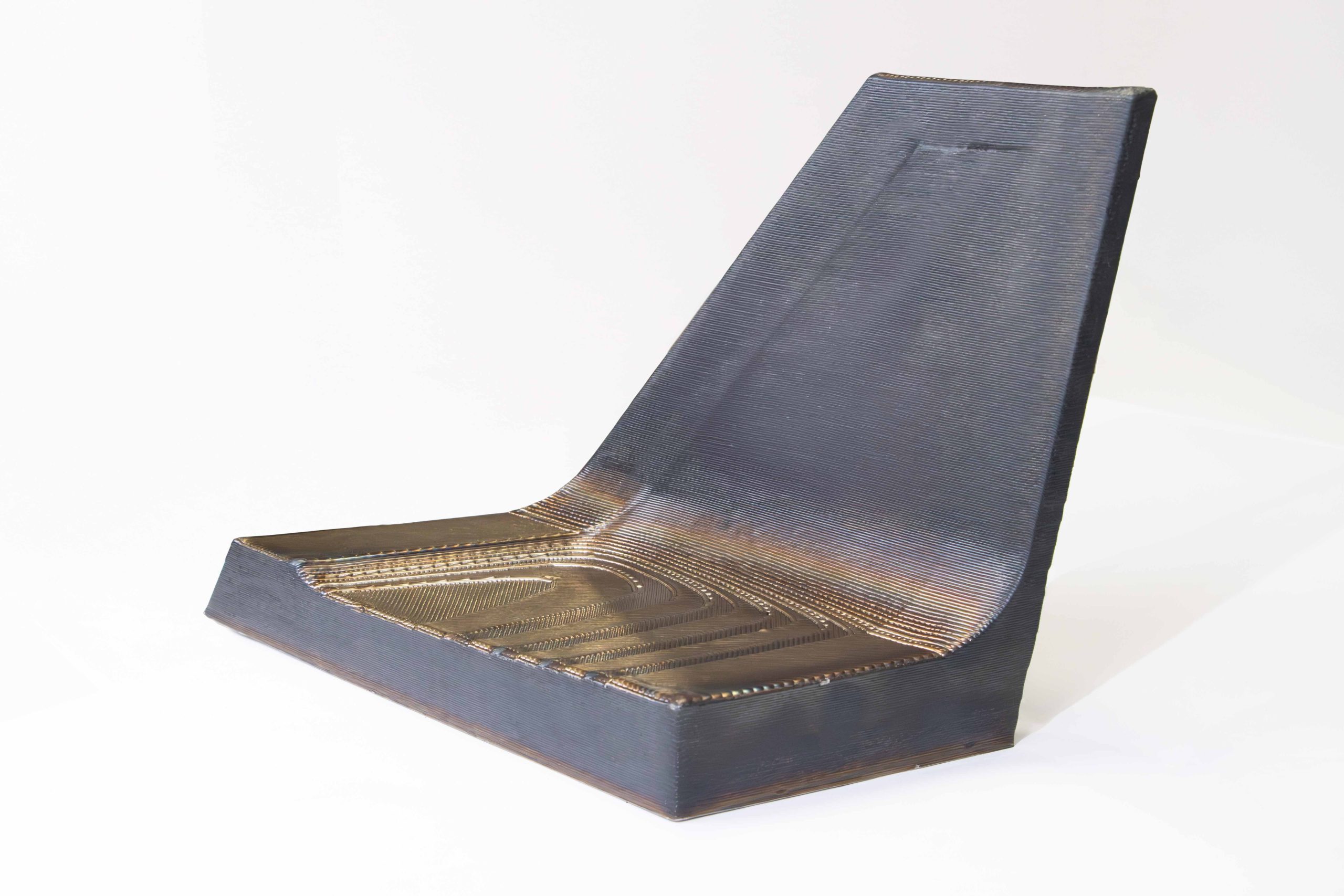

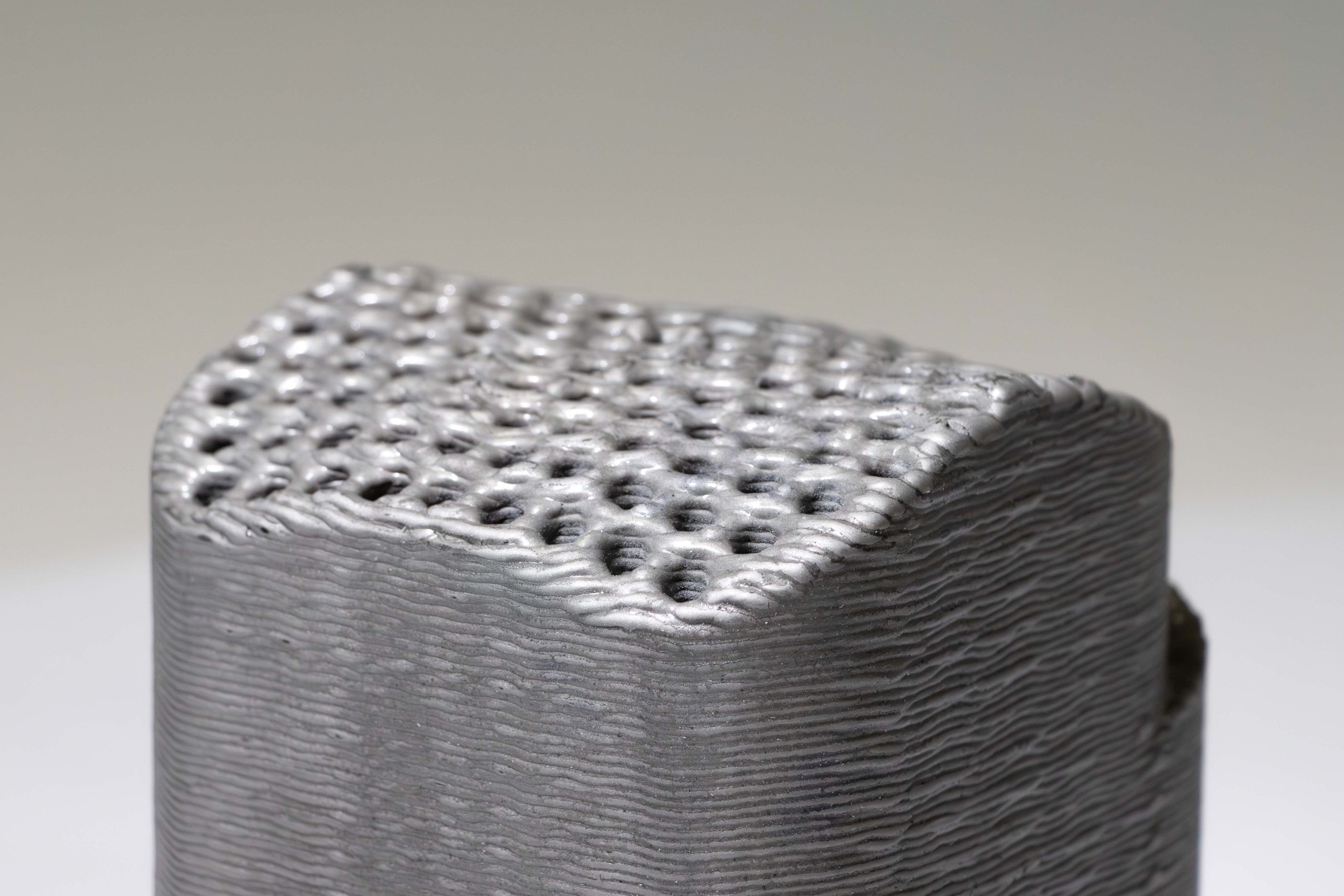

Mold-free production of tailored metal parts

Case study developed by Daidore

Daidore, a Japanese compa...

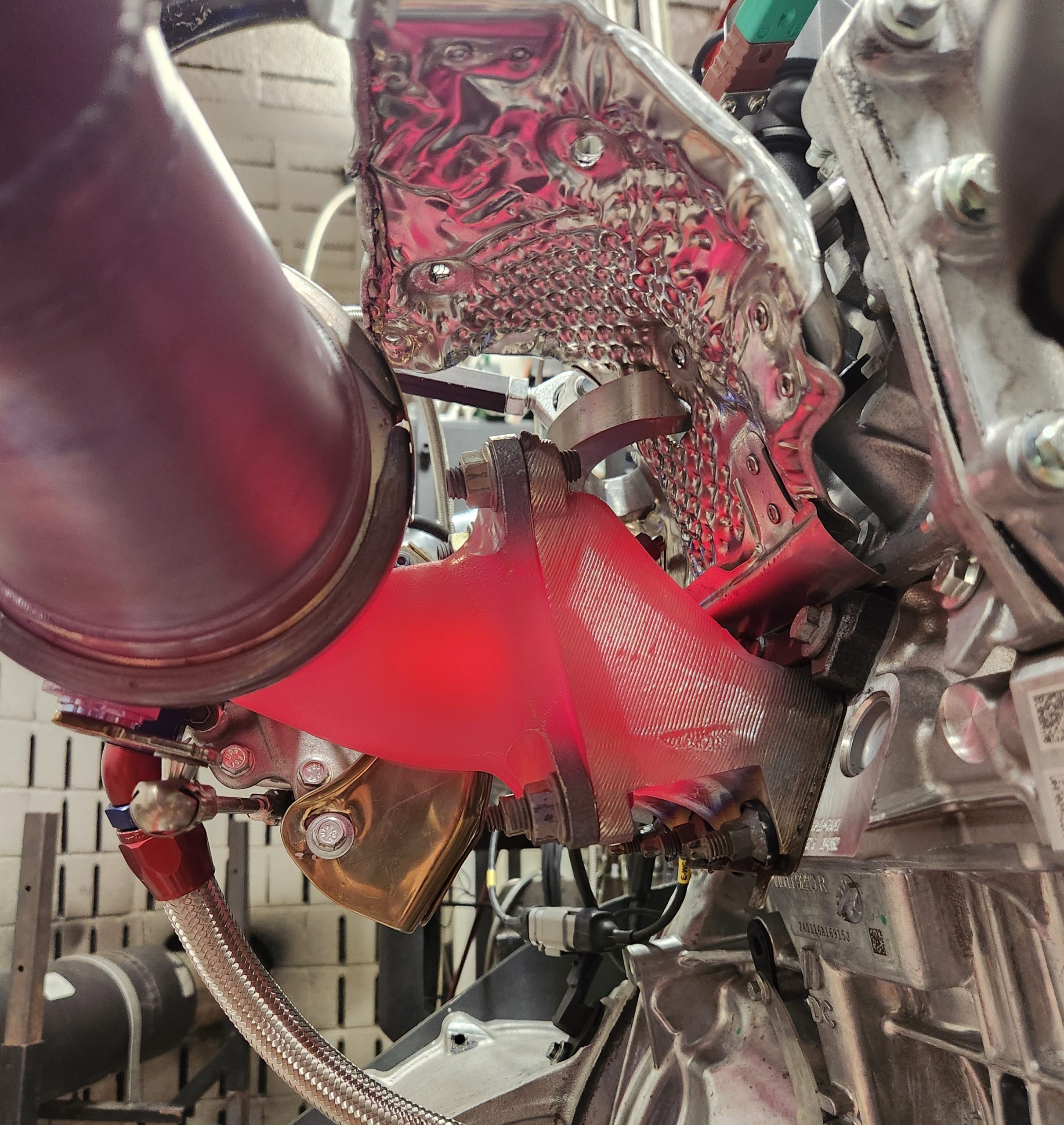

Producing a temperature resistant racing car part

Case study developed by ERM

ERM Fab&Test is one of Me...

Upgrading an anti-cavitation valve with additive manufacturing

Use case developed by Meltio

This use case presents an in...

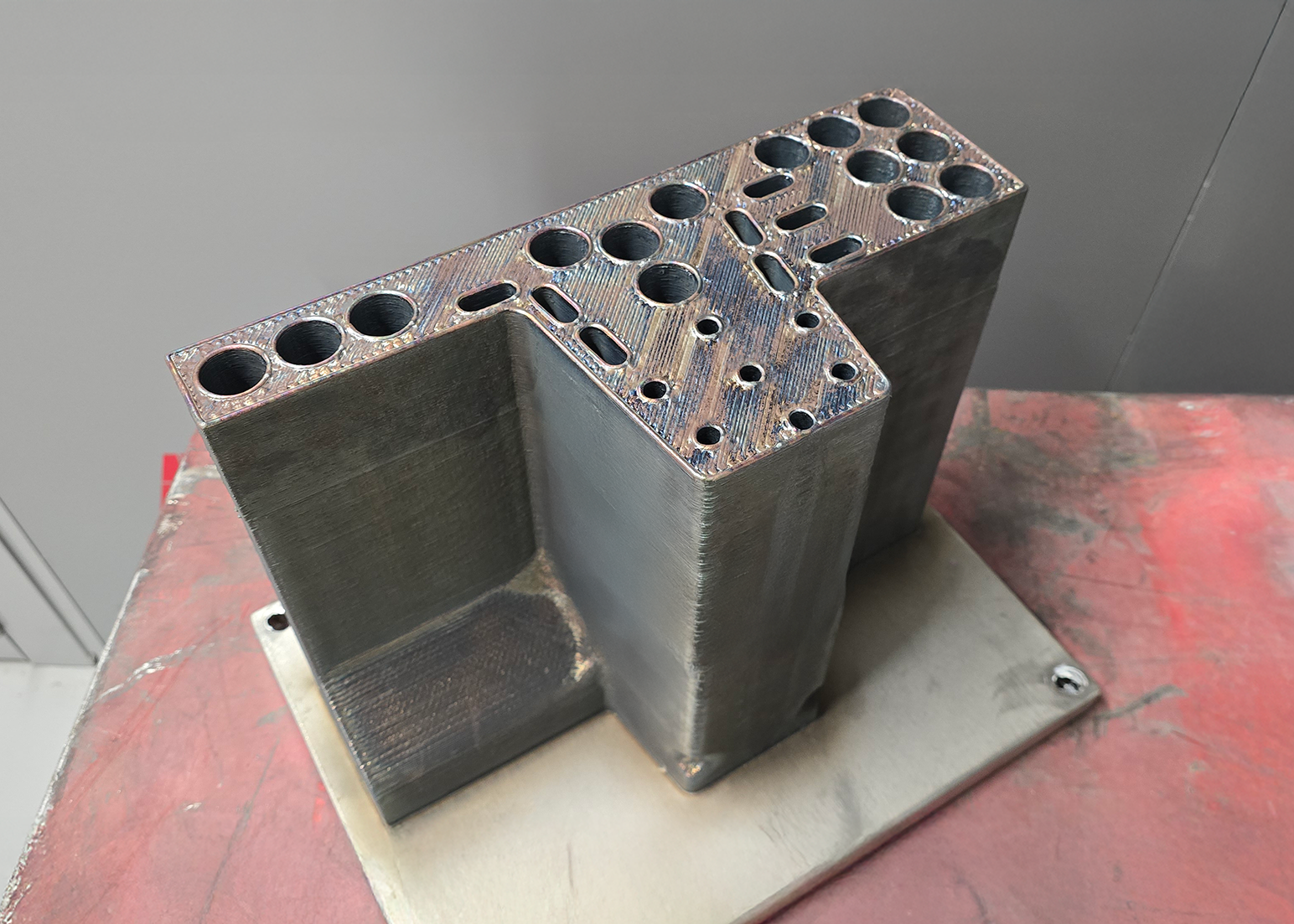

Cost and time saving solutions through robotic metal 3D printing

DPR AUTOMATISMOS, a company of José Antonio Labandeira, was ...

On demand production of eductors for naval systems

This entry continues our defense spare parts series, highlig...

Achieving a 300mm reliable diffuser no one could replace

When legacy equipment fails, replacement parts are often dif...