Bridging the skills gap: Why leading universities are choosing Meltio

In an era where supply chain resilience and workforce readiness are paramount, higher education faces a critical mandate: to bridge the widening gap between academic theory and rapid industrial application. Leading this charge are Kansas State University (K-State) and the University of Arizona, institutions that have successfully redefined their manufacturing capabilities through a strategic partnership with Phillips Corporation’s Hybrid Division.

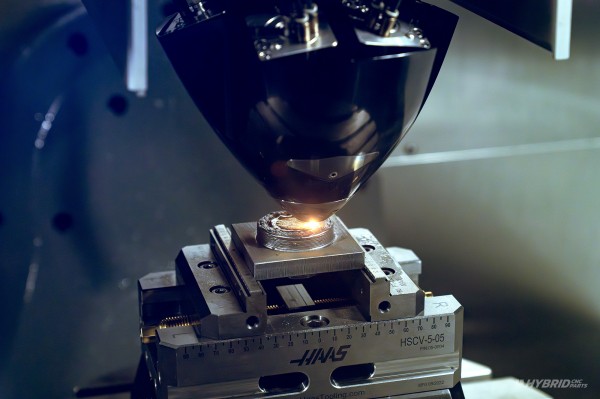

By integrating Meltio’s wire-laser DED technology directly onto robust Haas CNC platforms, these universities have bypassed the limitations of traditional, hazardous powder-based systems. This report explores how this accessible hybrid approach is delivering dual-use value: empowering K-State’s Technology Development Institute (TDI) to manufacture defense-certified components for the Department of Defense, while enabling the University of Arizona to transform novice engineering students into skilled hybrid operators in just two weeks.

1. The industrial skills gap

The manufacturing sector faces a critical paradox: the industry is rapidly advancing toward hybrid workflows (combining additive and subtractive), yet the educational pipeline often struggles to keep pace. Universities are trapped between two difficult realities. On one hand, traditional industrial additive systems are often prohibitively expensive, hazardous (powder-based), and require specialized infrastructure. On the other hand, «hobbyist» 3D printers fail to prepare students for the rigorous demands of aerospace and defense, among other industries.

This gap leaves engineering graduates ill-equipped for modern shop floors, and it prevents research institutions from delivering high-level educational programs.

2. Why Powered by Meltio technology fits the Campus

Two leading institutions, Kansas State University (K-State) and the University of Arizona, found the answer in the Phillips Hybrid system. By integrating the Meltio Laser DED (Directed Energy Deposition) head directly into a standard Haas CNC machine (UMC-1000SS and VF-2), these universities created a «lab-in-a-box» solution.

This setup offers a seamless transition between printing and machining within a single enclosure, democratizing access to advanced metallurgy without the safety risks of loose powder.

Safety first

Unlike powder-bed fusion systems that require respirators and explosion-proof rooms, Meltio uses standard welding wire. This makes it safe for undergraduate labs and classrooms.

Accelerated learning curve

The University of Arizona proved that students with zero prior CNC experience could progress to producing certified parts in just two weeks.

Dual-use capability

The system is not just for teaching; it is an industrial workhorse. It supports dual-wire printing for complex alloys (Stainless, Inconel, Nickel), enabling high-level research alongside undergraduate training.

Wire: Safer and cheaper than powder

Up to 90% material cost reduction: Wire feedstock is a standard welding commodity, widely available and significantly cheaper than powder.

Safety first: Meltio uses standard wire. This makes it inherently safer by eliminating the risk of powder inhalation or fire.

3. Kansas State University: Defense-ready certification

At K-State’s Technology Development Institute (TDI), the stakes were higher than just grades. Partnering with defense innovator Overmatch Inc., they needed a system capable of producing deployable parts for the U.S. Department of Defense (DoD).

The Result: The hybrid cell didn’t just produce prototypes; it manufactured defense-certified components approved for U.S. military use.

«The training was detailed, the support continued afterward, and their extra effort got us up and running on time,»

Quinton Berggren, Engineer at TDI.

4. University of Arizona: Democratizing Advanced Manufacturing

The University of Arizona faced a curriculum challenge: how to take students from theory to practice without overwhelming them. They integrated the Meltio system into a Haas VF-2 platform.

The Result: The system became a recruitment tool and a research engine, supporting projects for Honeywell and international collaborations with Politecnico di Milano.

«This training transformed me from being a complete novice to being able to produce full parts.»

Mohamed Ibrahim, a PhD student.

5. From Novice to Pro in 14 days

The University of Arizona proved that students with zero prior CNC experience could progress to producing certified parts in just two weeks. Below is a breakdown of the hybrid syllabus that makes this rapid upskilling possible.

Sample 2-week Hybrid syllabus

| Timeline | Phase | Key Learning Modules |

| Week 1 | Subtractive Foundation (CNC) | • Machine Basics: Introduction to Haas CNC operations and safety. • Setup: Work offsets, tool offsets, and calibration. • Programming: G-Code basics and standard Haas control interface. • Execution: Machining a test substrate to prepare for deposition. |

| Week 2 | Additive Mastery (Meltio) | • Laser Alignment: Calibrating the Meltio deposition head. • Slicing for DED: Toolpath strategies for adding material vs. cutting it. • Hybrid Workflow: Running a single program that prints a near-net shape and immediately machines it to tolerance. • Troubleshooting: Identifying common deposition errors in real-time. |

6. Technical & operational benefits

The Phillips Hybrid integration delivers quantifiable advantages for educational institutions:

Cost efficiency

Uses standard welding wire, which is significantly cheaper than metal powder.

Space optimization

Combines two machines (Mill + Printer) into the footprint of one, maximizing valuable lab space.

Material flexibility

Capable of printing and machining Stainless Steel, Carbon Steel, Nickel Alloys, and Inconel in a single setup.

Industry support

Phillips’ ongoing support and training, ensuring the machines didn't sit idle

7. Real-world impact & Alumni tracking

The true measure of this technology is not just in the lab, but in where it leads.

Kansas State University: The Technology Development Institute (TDI) partnered with defense innovator Overmatch Inc. to produce defense-certified components for the U.S. military. The system allowed them to bypass broken supply chains and print deployment-ready parts on campus.

University of Arizona: The hybrid cell serves as a research engine for major industry players.

Current Alumni Impact:

Students who transition from complete novices to a hybrid experts, now conducting advanced research on process-property relationships in superalloys.

Undergraduates are currently working on Honeywell-sponsored projects, directly feeding into the aerospace workforce pipeline.

Students are engaging in design-repurposing efforts with Politecnico di Milano, broadening their global engineering exposure.

8. Building a workforce pipeline from classrooms to factories

The experiences of K-State and the University of Arizona demonstrate that the barrier to entry for metal additive manufacturing has collapsed. By adopting the Phillips Hybrid system, universities can now offer DoD-level capabilities in a student-safe environment. This is not just about buying a machine; it is about installing a workforce development pipeline that connects the classroom directly to the factory floor of the future.

To know more how Meltio is helping universities and technical centers worldwide, click HERE