Validated industrial applications

Near-net shape parts with the best efficiency

Overcoming supply chain limits

From unique applications to the best efficiency in cost, without losing top mechanical properties

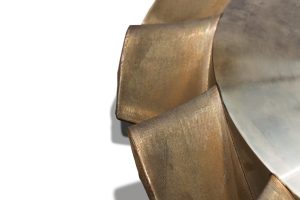

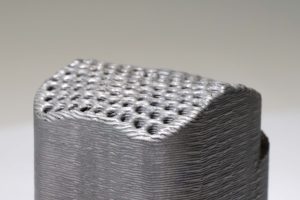

Hard-facing & Cladding

Apply wear-resistant coatings onto low-cost substrates for die repair and tooling life extension.

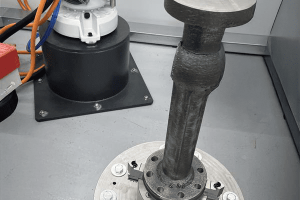

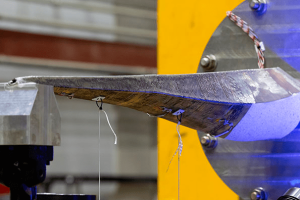

Critical structural components

Print fully dense parts that withstand high fatigue loads in extremely demanding environments.

Spare parts on demand

Eliminate physical inventory. Print replacement parts locally to reduce downtime and logistics costs.

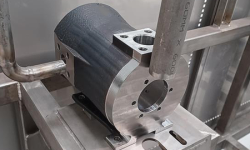

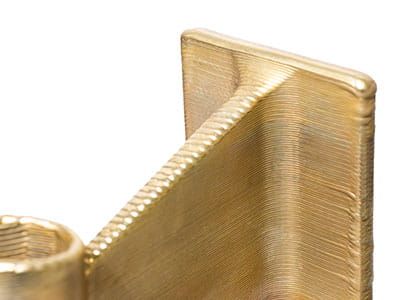

Reduced machining time

Print geometries with minimal stock allowance, reducing CNC cycle times and cutting tool wear.

Is your part suitable for Wire-Laser DED?

Meltio Wire-Laser DED is ideal when conventional manufacturing or other metal AM technologies become inefficient or limiting. Your part is a good fit for Meltio if it meets several of the following criteria:

- Medium to large size: Ideal for parts where Powder Bed Fusion (SLM) is too slow or expensive. (Sweet spot: >100mm to 1m+)

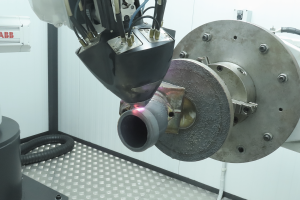

- Hybrid requirements: Parts requiring addition to existing geometries (flanges, features on shafts, or repairs).

- High-cost materials: Drastic ROI when replacing billet machining of expensive and hard to machine metals such as Titanium, Inconel, or Tool Steel due to reduced waste (Buy-to-Fly ratio).

- Moderate complexity: Geometries that would traditionally be cast or forged, with minimum wall thickness above 2.0 mm.

*Rule of thumb: If your part is too large for PBF, too precise for WAAM, and too wasteful or slow to machine, Meltio Wire-Laser DED is likely the right solution.

Applications per industry

Drastic waste reduction

Material waste <10%

Safety with reactive materials

Wire feedstock

High-temp alloy validation

Ensured structural integrity

Component repair

Extending lifecycle

Conformal cooling channels

Reduce cycle times

Hybrid mold repair

Restore tolerance

Multi-material prints

High-performance components

Faster production

And cost-efficient

Point-of-need manufacturing

Deployable solution

Legacy parts sustainment

Print replacement parts

Field repair capability

Back to service faster

Enhanced operational readiness

Avoid supply chain disruptions

On-site print and repair

Faster lead times

Avoid supply chain disruptions

No need to wait, no need of stock

Cut costs and downtime

Improved productivity

Reduce material waste

Near-net shape manufacturing

Applications developed by Meltio

Request an application assesment

Talk to an expert