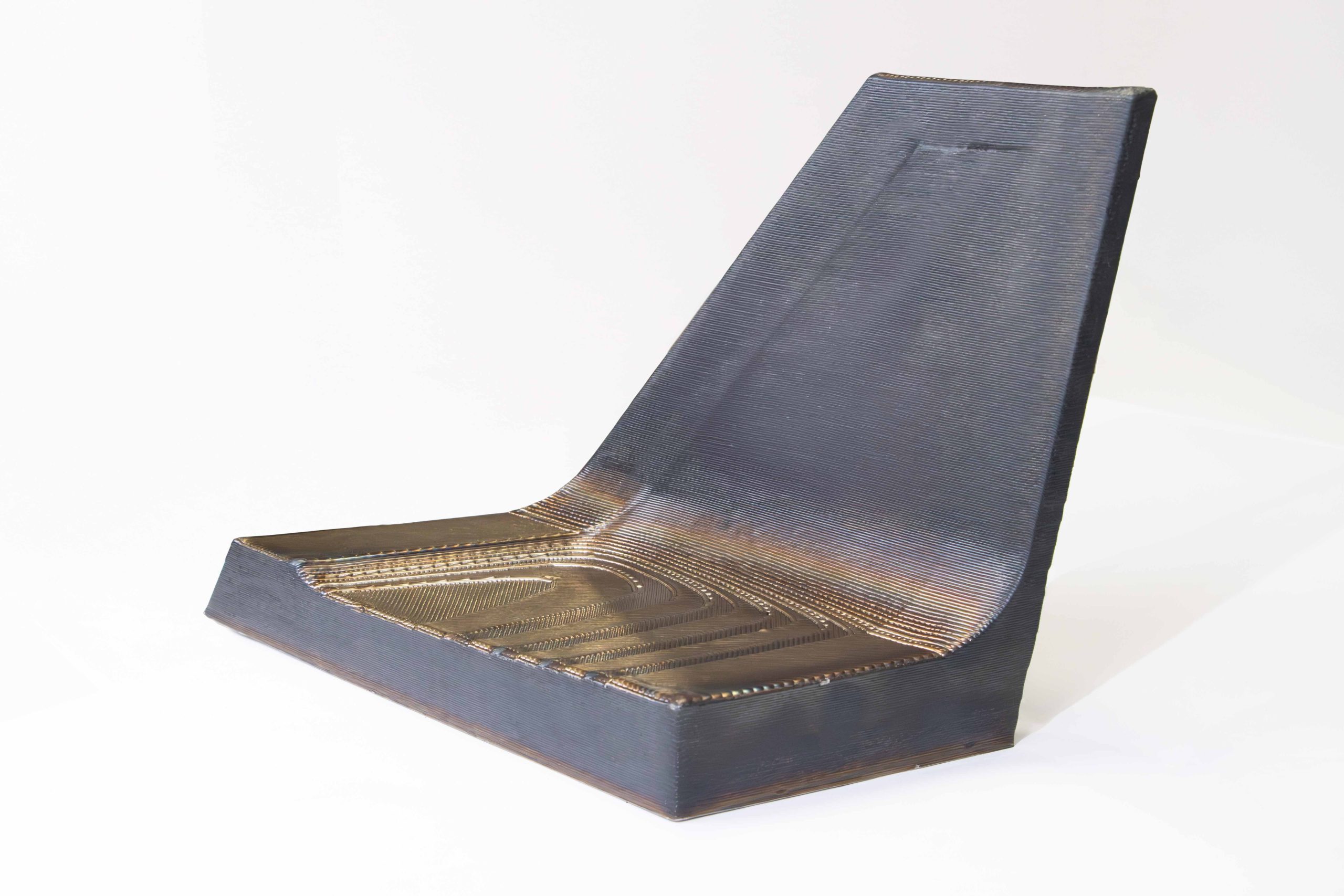

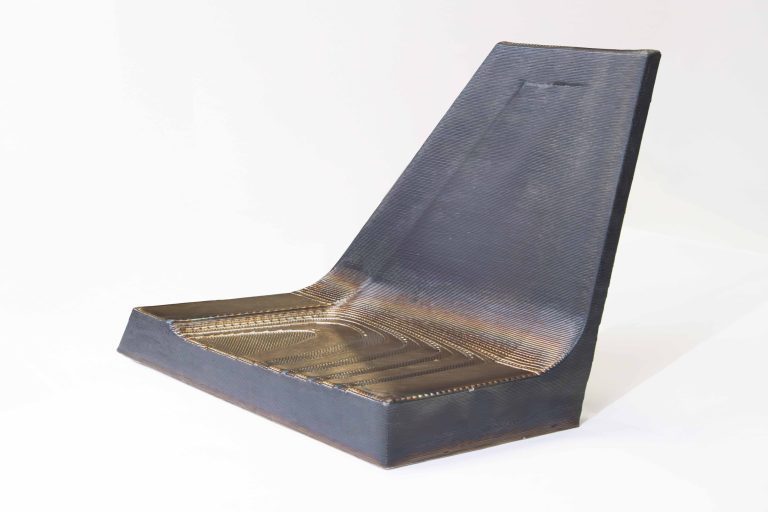

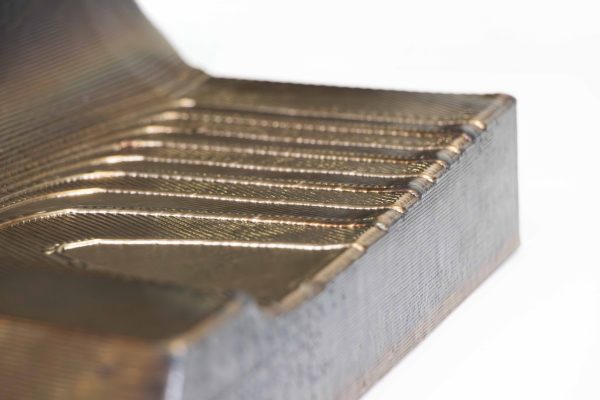

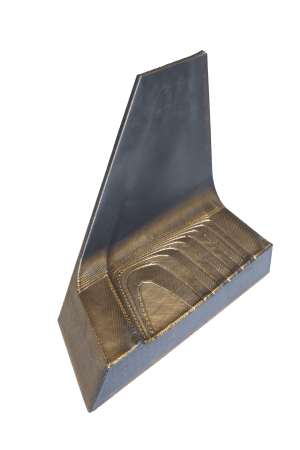

Use case developed by CATEC

Meltio continues to take metal additive manufacturing further through a new use case in collaboration with the Advanced Center for Aerospace Technologies (CATEC). This project reinforces the role of wire-laser Directed Energy Deposition (DED) as a strategic tool for advancing Spain’s aerospace sector.

Innovation in the Aerospace sector

The aerospace industry is one of the most demanding fields when it comes to quality, performance, and reliability. Every component must withstand extreme conditions while ensuring maximum safety and efficiency. To meet these challenges, CATEC has positioned itself as a European benchmark in applied research and technological development.

By incorporating Meltio’s wire-laser Directed Energy Deposition (DED) technology, CATEC is taking another step forward in its mission to bring cutting-edge solutions to aerospace manufacturing. This integration allows the center to explore new possibilities in both the production and repair of metal components, helping companies gain a competitive edge.

Driving aerospace manufacturing forward

Unlike other additive manufacturing technologies, Meltio’s solution is designed to seamlessly integrate into CNC machines, robotic arms, and standalone 3D printers. This compact and flexible approach makes it ideal for aerospace R&D environments where scalability and adaptability are key.

Some of the most relevant advantages of Meltio’s technology for aerospace include:

Component repair and manufacturing

Extending the life cycle of critical aerospace parts while reducing waste and costs

Faster prototyping and production

Shortening development times and accelerating innovation cycles

Multi-material capabilities

Allowing the creation of hybrid or functionally graded components that meet demanding performance requirements

Industrial scalability

Offering aerospace manufacturers the option to start with R&D projects and scale up to full production without major infrastructure changes

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

Proven success in other industries

This collaboration with CATEC adds to Meltio’s growing list of success stories in multiple high-performance industries:

- Automotive: Companies like DMZ and ERM have leveraged Meltio’s technology to produce exhaust manifolds and turbo components. These parts not only reduced manufacturing times and costs by up to 70%, but also endured real-world performance testing under extreme conditions.

- Defense: The U.S. Navy has successfully used Meltio to reproduce obsolete spare parts, such as a naval eductor for the USS Arleigh Burke, in less than 58 hours. Other applications include impellers and mission-critical components where downtime is not an option.

- Energy: Engineering firm Roez s.r.o. manufactured a complex turbine housing in a single piece, eliminating the need for assembly and significantly reducing lead times.

Turn a robot arm into a metal 3D printing system with no inherent size constraints. lt is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

The Meltio Engine integrates with any robot arm manufacturer and interface on the market. Meltio Space slicer software for robots is compatible with ABB, Kuka, Fanuc, Yaskawa and Siemens

Aerospace demands parts that are strong, lightweight, and reliable under extreme conditions. Meltio’s wire-laser DED technology makes this possible by enabling cost-effective repairs, fast prototyping, and even multi-metal components. Its seamless integration into CNCs and robotic arms gives aerospace companies the flexibility to innovate quickly and keep production efficient.

Wire feedstock proves more affordable and safer than powder-based alternatives.

Looking ahead

The collaboration between Meltio and CATEC is a clear example of how industry and research centers can join forces to drive technological progress. By combining Meltio’s expertise in wire-laser DED with CATEC’s leadership in aerospace R&D, this alliance will open new pathways for innovation, sustainability, and competitiveness.

Meltio will continue to work closely with partners worldwide to expand the possibilities of metal additive manufacturing, ensuring that industries as critical as aerospace benefit from the efficiency, flexibility, and performance of its technology.