The safe, open, and affordable

Metal 3D Printing standard for Academia

Teach modern manufacturing on a safe, wire-laser system. It’s cleaner than powder, cheaper to run, and integrates directly with CNC and robot arms.

Why top-tier universities choose Meltio

Meltio LMD (Laser Metal Deposition) technology breaks down the barriers of traditional metal additive manufacturing, making it the ideal choice for campus labs and training centers.

Safety first

Our wire-laser process is clean, using standard welding wire and inert gas. It eliminates the need for hazmat suits, sealed rooms, and explosion-proof filtration, making it safe for students and standard lab environments.

Accesible and affordable

With minimal site requirements and low-cost feedstock, it drastically lowers acquisition and operating costs compared to powder-bed systems.

Open platform for innovation

Use our open system for new material parametrization, dual-wire alloy research, and custom robot integrations.

Minimum space requeriments

You don’t need to build a new facility or throw out old machines. Our engine retrofits directly onto the CNC mills and robot arms sitting in your lab right now, while the Meltio M600 fits anywhere.

Open Materials. Open Parameters. Open Access.

A robust engine for PhD-level research and industrial innovation.

Material science & alloy development

Dual-wire technology:

Combine materials in-process to create functional gradients or entirely new alloys.

New material parametrization:

Our open platform allows for deep metallurgical exploration.

Process control & robotics

Fundamental research:

Integrate sensors for process control or heated print beds for thermal analysis.

Robotic freedom:

Explore metal freeforming, multi-robot simultaneous toolpaths, and digital twin creation with our flexible engine integration.

Real-world impact on Campus

From Novice to Pro in 2 weeks

Students entered with zero CNC or additive experience.

A Phillips Additive Hybrid system was in place.

A full "design-to-part" workflow where students are printing and machining certified parts in under 14 days. The system now supports Honeywell-sponsored capstone projects and collaboration with Politecnico di Milano.

"This training transformed me from being a complete novice to being able to produce full parts."

Aerospace innovation with advanced additive manufacturing

Every component must withstand extreme conditions while ensuring maximum safety and efficiency.

By combining Meltio’s expertise in wire-laser DED with CATEC’s leadership in aerospace R&D, this alliance will open new pathways for innovation, sustainability, and competitiveness.

"This integration allows the center to explore new possibilities in both the production and repair of metal components, helping companies gain a competitive edge."

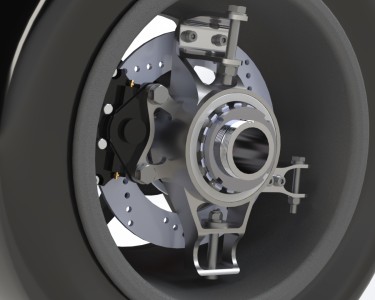

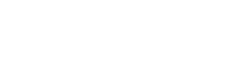

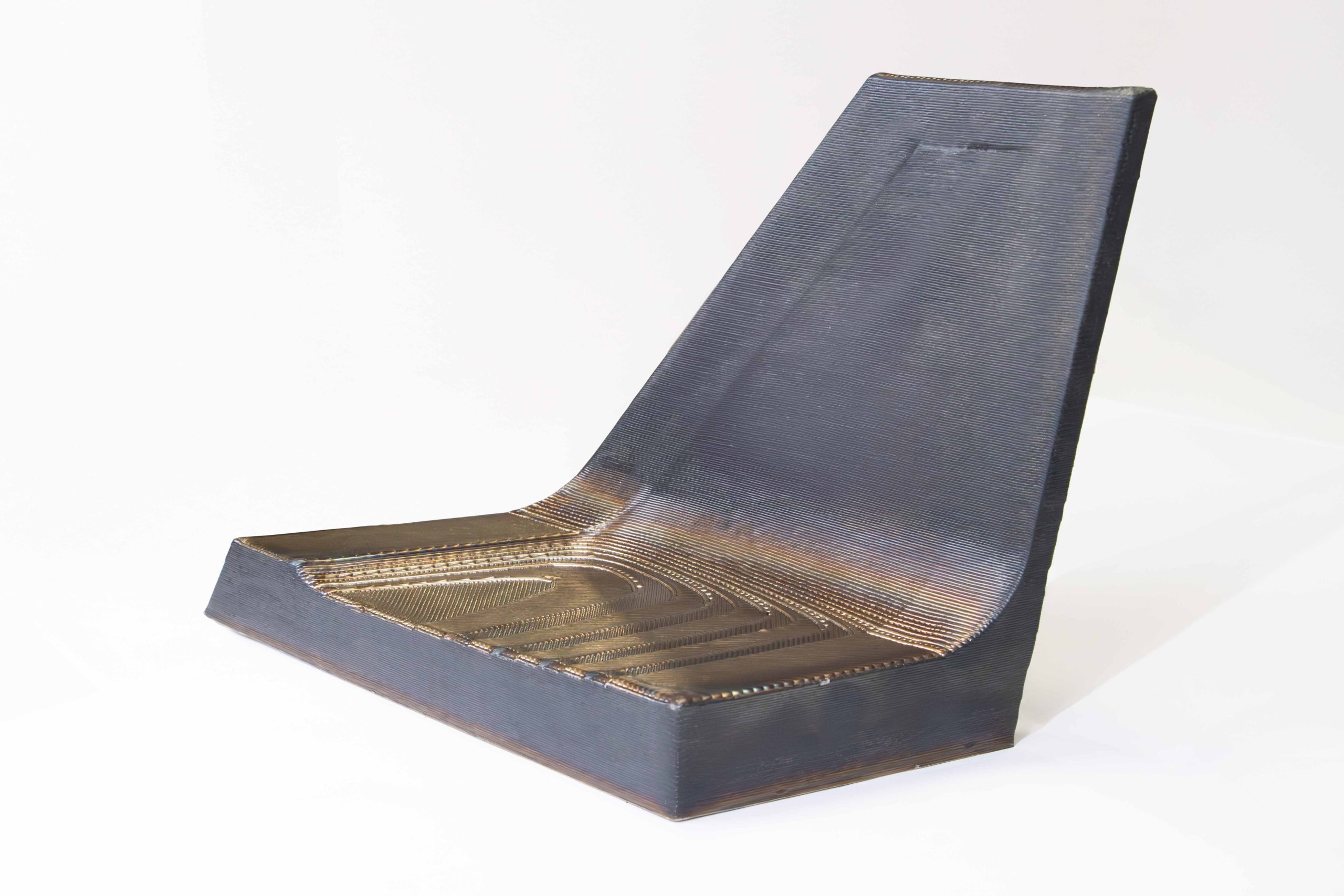

Manufacturing 35% lighter titanium uprights for Formula Student

Striving for a massive architectural shift to comply with racing regulations.

Traditional manufacturing couldn't provide a solution.

Switched to Meltio technology to move from a standard mechanical assembly to a highly optimized, high-performance component.

“This collaboration not only allowed us to enhance the performance of our race car but also to massively expand our knowledge of one of the most promising technologies shaping the future of manufacturing.»

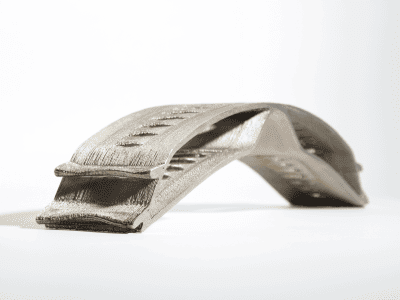

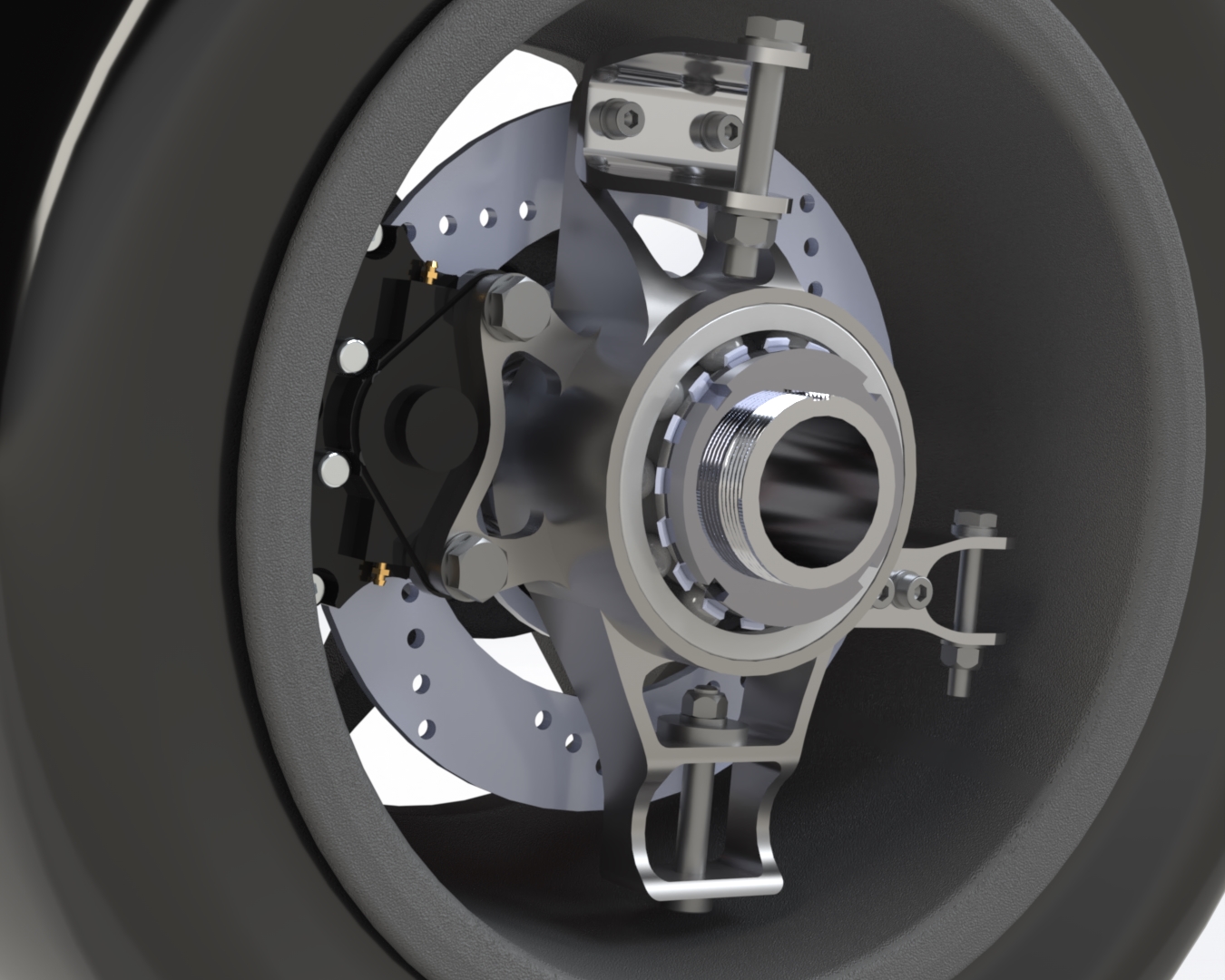

Cutting costs and material use in an aerospace project

The aim was to design and fabricate a lightweight yet structurally robust tripod for aerospace that significantly reduces material usage while maintaining the necessary mechanical properties.

The University has a Meltio M600.

The technology facilitates explorations into geometries and material combinations previously inaccessible, driving progress in functional gradient materials and lightweight structures.

"The decision to adopt Meltio’s wire-laser metal 3D printing solution—specifically the new Meltio M600 wire-laser metal 3D printer—stems from its notable advantages in cost-effectively producing high-quality metal parts."

Bridging Academia and Defense

Producing deployable parts for defense innovator Overmatch Inc.

Meltio Engine integrated with a Haas UMC-1000SS.

Production of defense-certified components and a live training platform for future DoD operators.

"We didn't have success until we went to K-State. The training was detailed, and the support continued afterward."

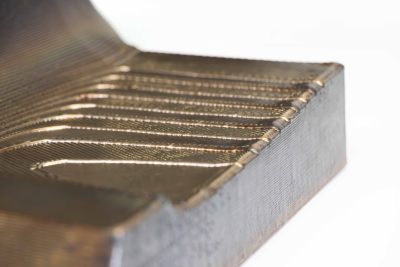

Sample parts of interest

Manufacturing of customized components on demand.

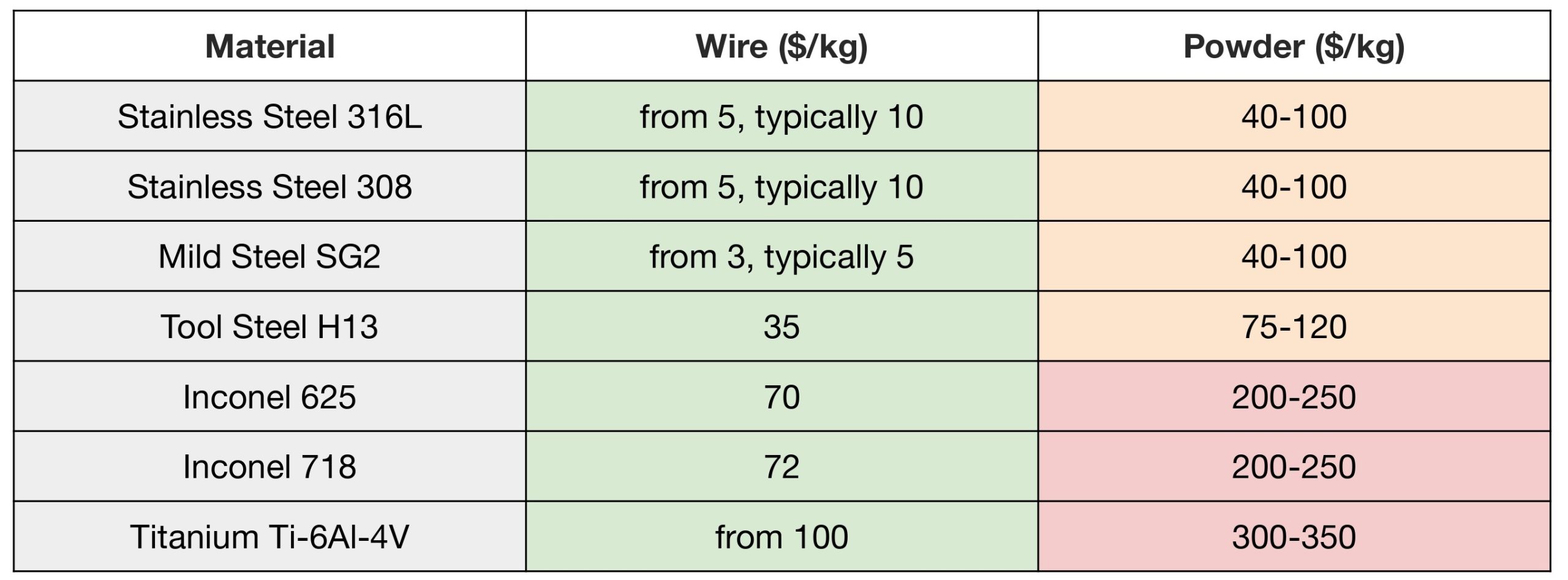

Wire is cheaper than powder

Molding the manufacturing workforce

Bridge the skills gap with a system that industry actually uses.

Hybrid Manufacturing

Uniquely enhances CNC education by combining additive and subtractive workflows in one cell.

CAM Test bed

An easy and low-cost way to teach Computer-Aided Manufacturing strategies for additive parts.

Industry ready

Students trained on Meltio are ready for sectors like Mining, Defense, Automotive, and Oil & Gas immediately upon graduation.

Supporting your lab's growth

We are an active partner in your institution's success.

- Grant support: We assist with technical data and applications for public grants to help secure funding for your lab.

- Curriculum & Training: Gain access to our academy and training centers to build your syllabus.

- Collaborative R&D: Join our ecosystem to develop materials and applications that feed directly back into industry.

Download Meltio’s Brochure for Defense

Ready to modernize your lab?

Connect with our team to discuss hardware options