South Korea’s Defense sector benefits

from 60% lighter components

Case study developed by AM Solutions

South Korea’s Defense sector benefits from 60% lighter components

Case study developed by AM Solutions

AM Solutions, one of the official partners of Meltio in South Korea, specializes in delivering modular additive manufacturing systems and solutions tailored for industries like aerospace, energy, shipbuilding, and defense. As part of an R&D initiative, AM Solutions collaborated with military logistics units to drastically improve the efficiency, ergonomics, and sustainability of critical tank components using Meltio’s metal 3D printing technology.

Challenging environments demand tougher solutions

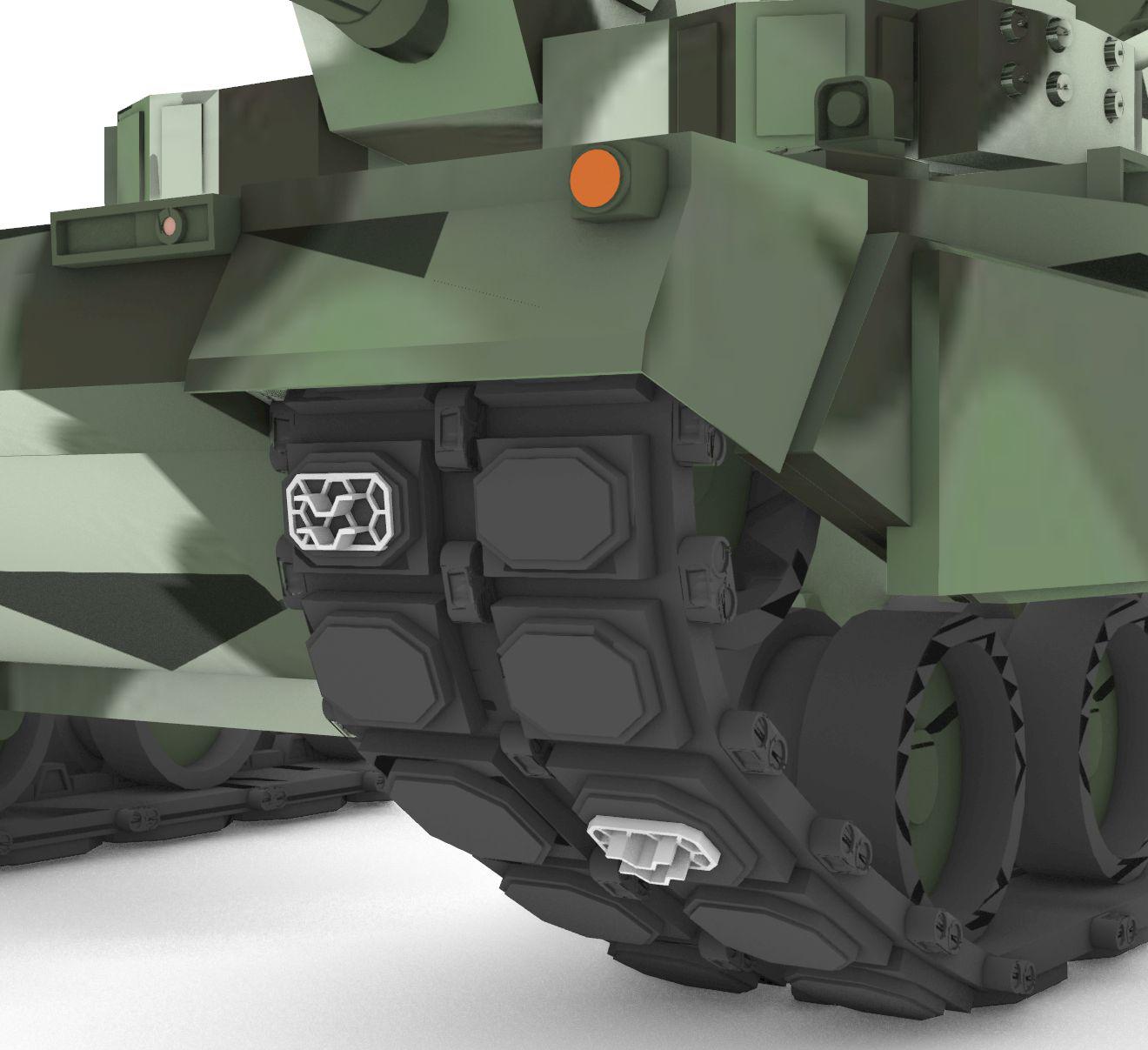

K2 Black Panther tanks operate in extreme environments, especially during winter tactical missions. In these conditions, the rubber pads usually mounted on tank tracks must be replaced by metal ice cleats (snow pads) to provide grip on frozen terrain.

These metal pads, weighing nearly 12 kg per unit, create substantial physical strain for soldiers who must install or remove 30–50 units per vehicle within tight time constraints. The excessive weight also affects the overall operational efficiency of the tank.

A solution was needed to lightweight the component, while maintaining its functionality and strength under harsh conditions.

A new lightweight snow pad to solve old problems

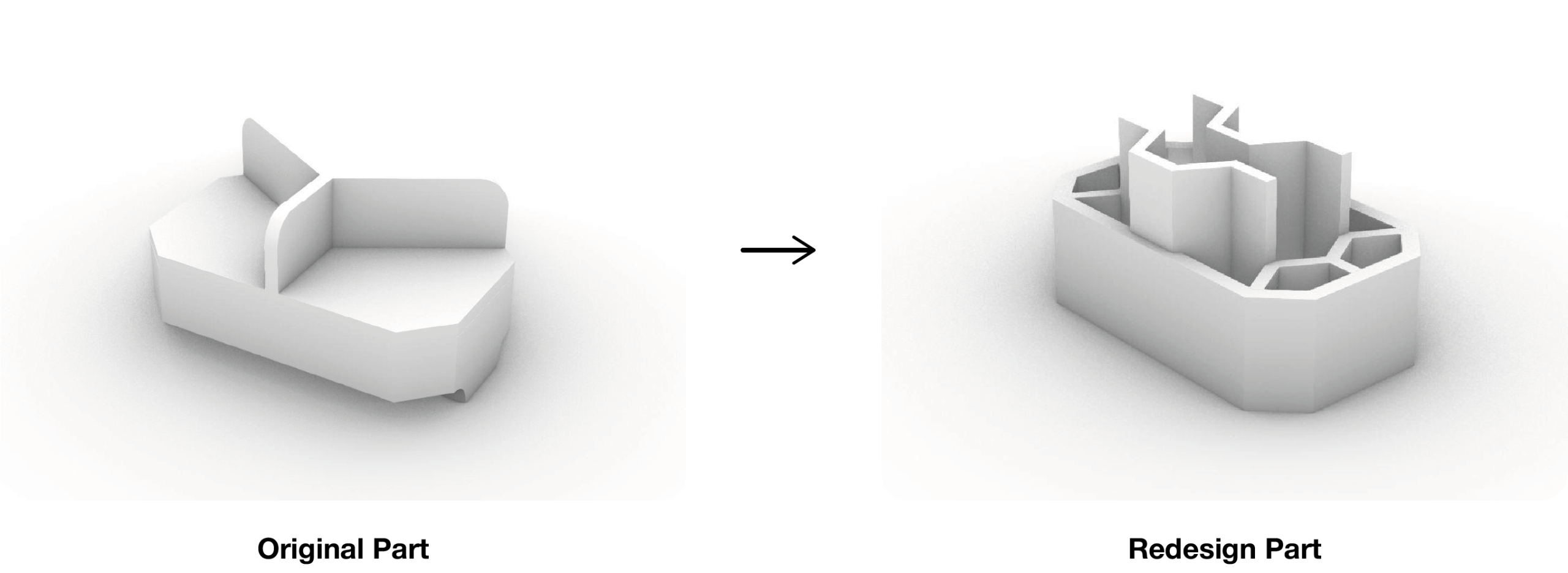

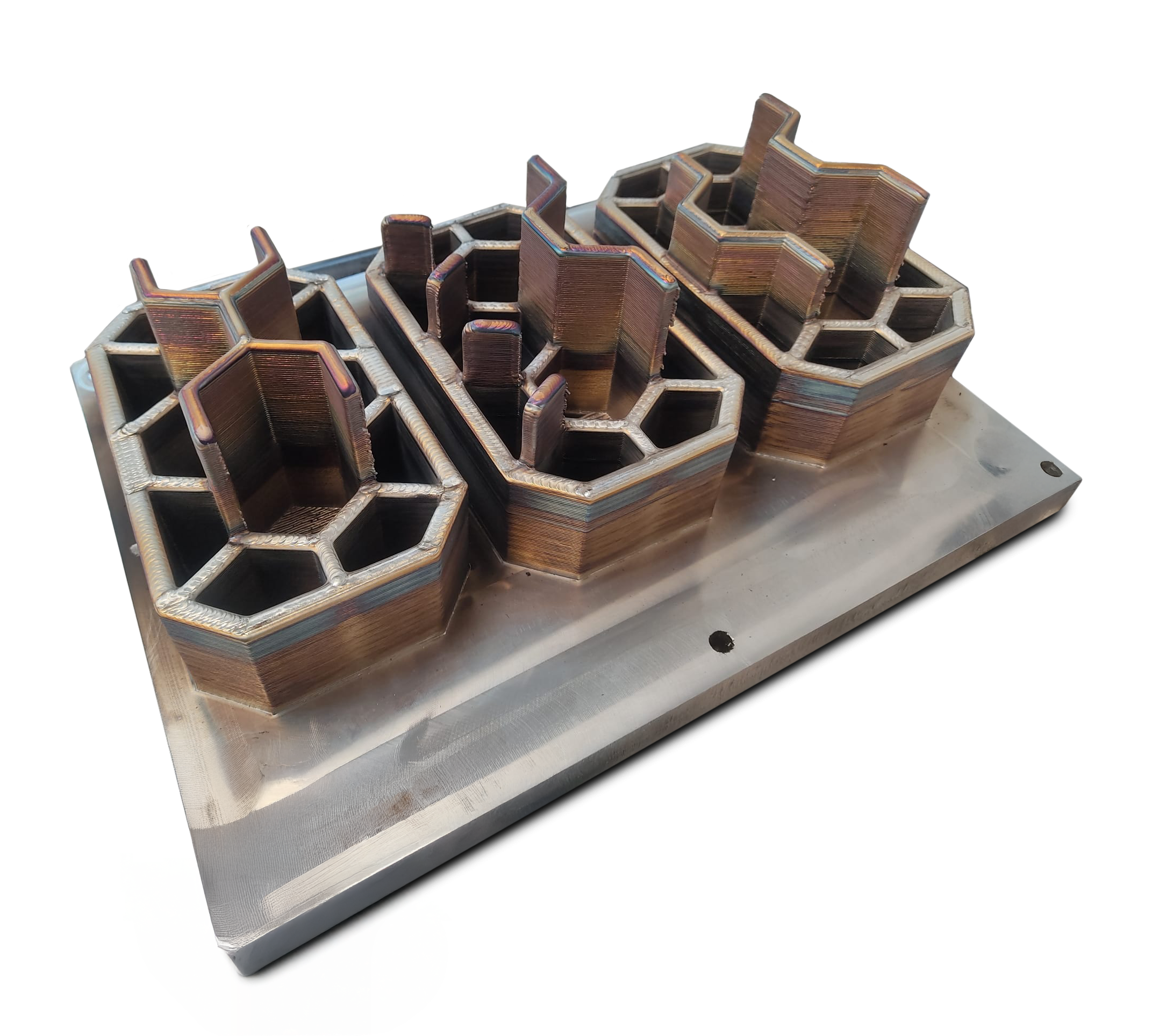

To overcome the limitations of conventional snow pads, AM Solutions leveraged the Meltio M600 system, which uses Laser Wire Directed Energy Deposition (LW-DED) technology to manufacture and test a lightweight redesign of the component.

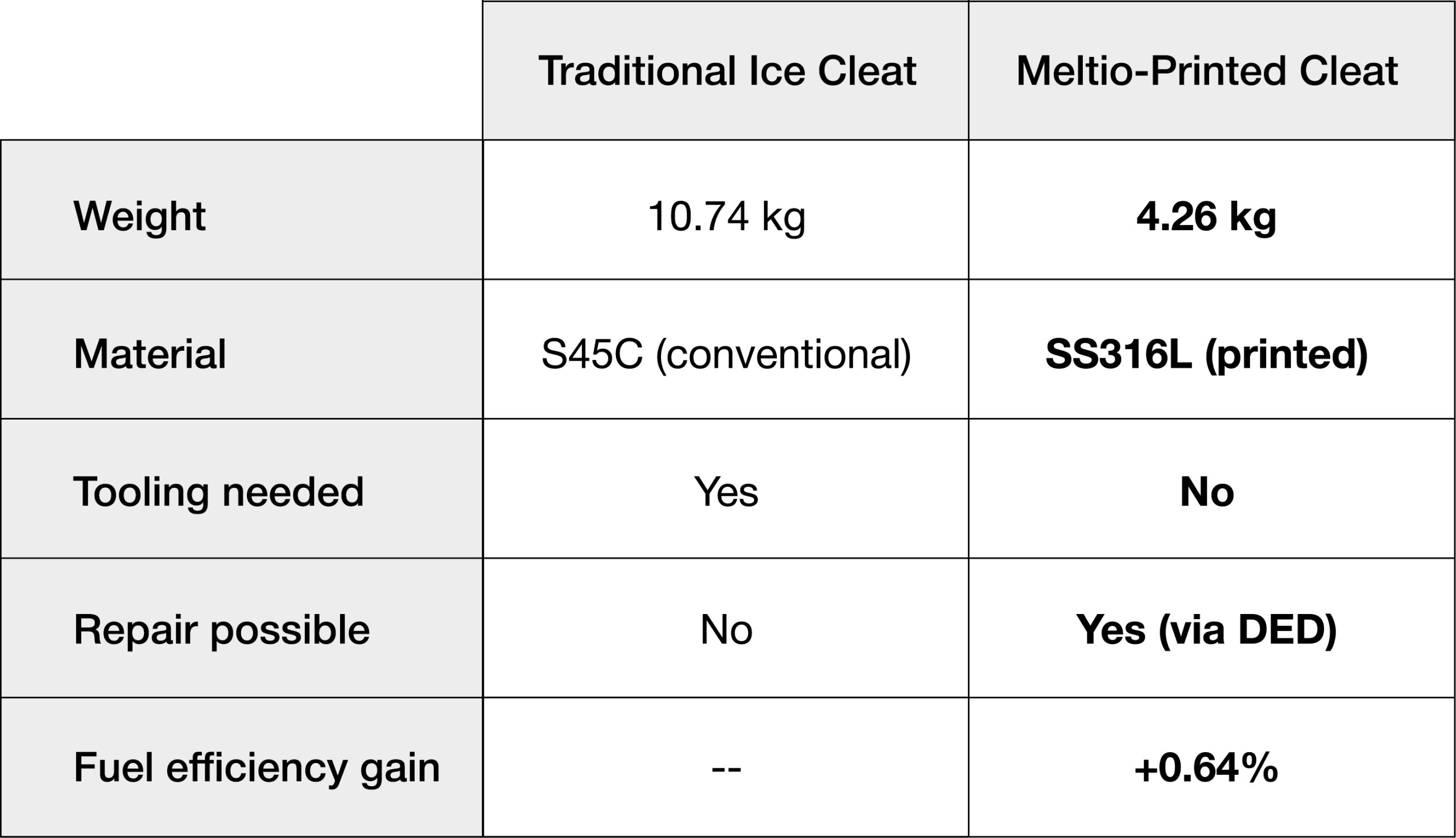

Using a honeycomb structure optimized for additive manufacturing, the team reduced the weight of the snow pad from 10.74 kg to 4.26 kg, a 60% reduction. The redesigned part maintained all mechanical properties required to withstand the heavy load and stress imposed by the tank in operation.

In addition, the redesign included enhancements for terrain-specific performance by integrating features inspired by tread patterns and global case studies. The result was a structurally sound, application-optimized component, fabricated without tooling, molds, or post-processing.

Honeycomb structure optimized for AM

Weight reduction from 10.74 kg to 4.26 kg

Maintaining mechanical properties

Enhancements for terrain-specific performance

Fabricated without tooling, molds, or post-processing

Over 60% weight reduction

Minimizes physical burden on soldiers and improves tank energy efficiency

No tooling required

Enables rapid prototyping and design iterations

On-demand production

Reduces inventory and supports real-time logistics

Wire-based DED process

High material utilization (up to 99%) and minimal waste

Over 60% weight reduction

Minimizes physical burden on soldiers and improves tank energy efficiency

No tooling required

Enables rapid prototyping and design iterations

On-demand production

Reduces inventory and supports real-time logistics

Wire-based DED process

High material utilization (up to 99%) and minimal waste

Repairability

Damaged parts can be selectively repaired instead of replaced

Scalability

Three pads produced simultaneously in one print cycle

Improved fuel efficiency

~0.64% improvement in field trials

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

Same functionality, greater efficiency

To overcome the limitations of conventional snow pads, AM Solutions leveraged the Meltio M600 system, which uses Laser Wire Directed Energy Deposition (LW-DED) technology to manufacture and test a lightweight redesign of the component.

System: Meltio M600

The Meltio M600, with its built-in 3-axis probing system and work-holding solutions, is the ideal companion for your manufacturing operations.

Sector: Defense

Our technology combines safety, reliability, and easy integration. With Meltio, forces secure supply chains, extend platform lifecycles, and ensure assured availability where delay is not an option.

We partner with armed forces to secure that readiness and resilience are never compromised.

Material: Stainless Steel 316L

Wire feedstock proves more affordable and safer than powder-based alternatives.

Printing Time: Not disclosed (3 pads per cycle)

Adopting Meltio in the Defense sector

The South Korean defense industry is advancing on two major fronts using Meltio’s technology:

Digital reconstruction of legacy components

Many parts from past generations of military equipment are no longer in production. Additive manufacturing enables cost-effective, low-volume reproduction of these critical parts.

Tactical field repair

Through a mobile containerized solution named with:Holonic, Meltio’s print head is deployed directly to the field. This enables on-site production and repair of metal components, improving readiness and responsiveness in tactical environments.

Want to know more about printed parts properties?

Want to know more about printed parts properties?