Agile metal production

by replacing molds and casts

Case study developed by Daidore

Agile metal production

by replacing molds and casts

Case study developed by Daidore

Daidore Corporation is a Japanese manufacturing company with a focus on agile product development and efficient production of industrial components. The company has increasingly positioned itself as an early adopter of innovative manufacturing solutions to stay ahead in a competitive and rapidly evolving industrial landscape.

Faced with mounting pressure to streamline production and shorten development cycles, Daidore began evaluating advanced manufacturing technologies that could improve both productivity and product quality.

Strategic initiative to reduce costs and accelerate product development

The company’s traditional manufacturing processes—particularly when relying on cast parts or producing components without existing molds or design drawings—were proving too slow and expensive for today’s fast-paced industrial demands.

Additionally, Daidore needed a way to:

Accelerate its new product development timelines

Eliminate the dependency on expensive tooling and casting processes

Improve flexibility in responding to low-volume and custom orders

Reduce the cost and lead time associated with part procurement

Recognizing that additive manufacturing (AM) could address these pain points, Daidore established the implementation of 3D printing as a strategic corporate initiative.

Key features driving Meltio adoption

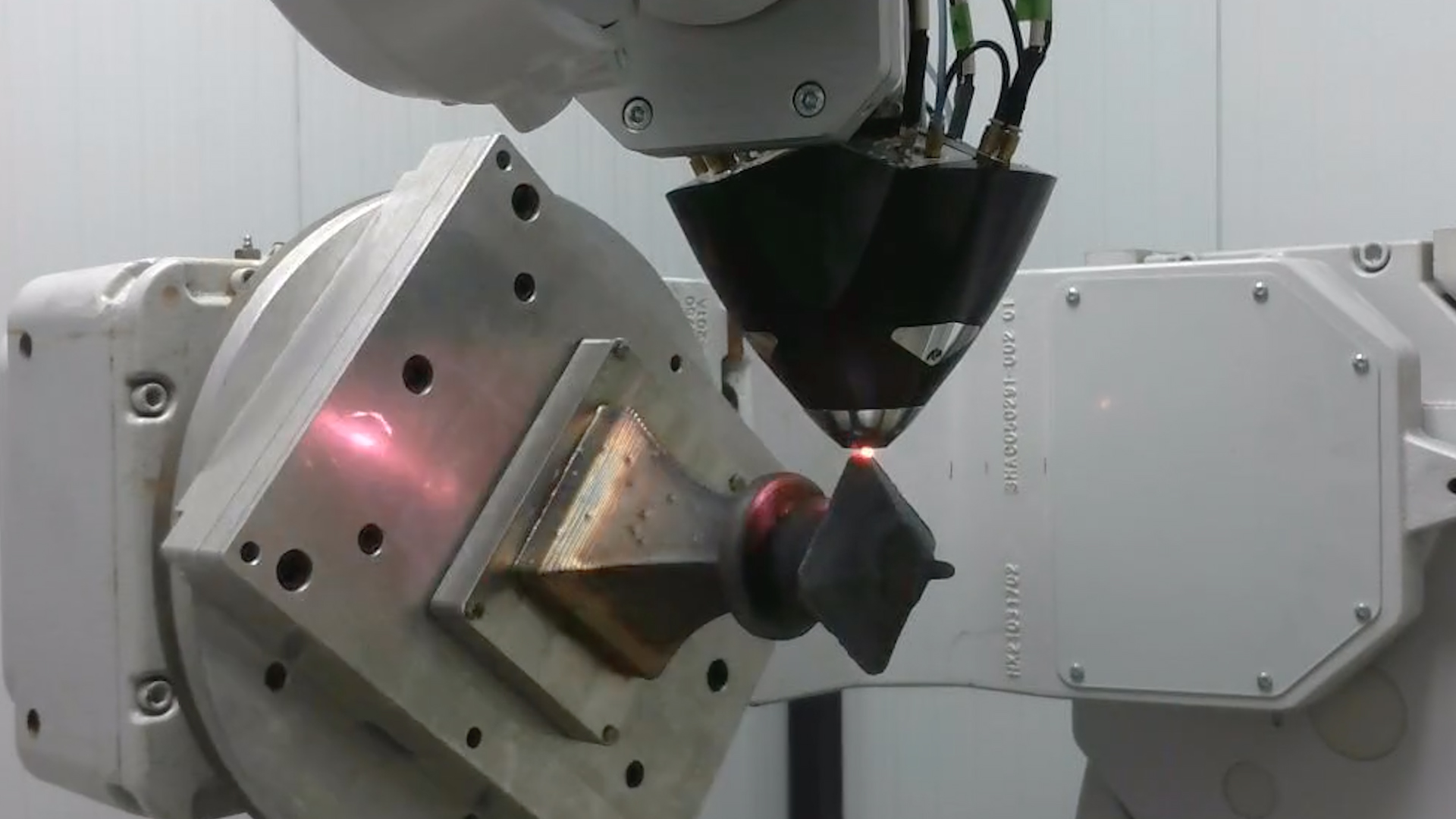

After evaluating several additive manufacturing technologies—including powder-bed fusion and binder jetting systems—Daidore selected Meltio’s wire-laser metal deposition technology, specifically the Meltio Robot Cell, due to its unique combination of affordability, flexibility, and scalability.

Key features that influenced the decision:

Material cost efficiency

Meltio’s wire-based AM uses welding wire, reducing material costs by up to 80–90% compared to powder-based systems

Advanced geometrical capability

The integration of a 6-axis robotic arm combined with a dual-axis rotating build table allows for the creation of more complex and organic geometries, while minimizing the need for support structures

Large build volume

The Meltio Robot Cell provides a build area of 2m × 1m × 1m, ideal for fabricating large parts or producing multiple components in one batch

Simplified infrastructure requirements

Unlike powder-based AM, Meltio’s system requires no explosion-proof facilities, sintering, or degreasing equipment—streamlining the implementation and reducing operational risk

Multi-material capability

Meltio enables the deposition of up to two different metal materials within the same part or job, opening new doors for functional and hybrid applications

The combination of these features provided Daidore with a cost-effective, versatile manufacturing tool that could be quickly adopted and scaled as needed.

From casting replacement to custom jigs

Since implementing the Meltio Robot Cell, Daidore has applied the technology across a wide range of manufacturing activities, including:

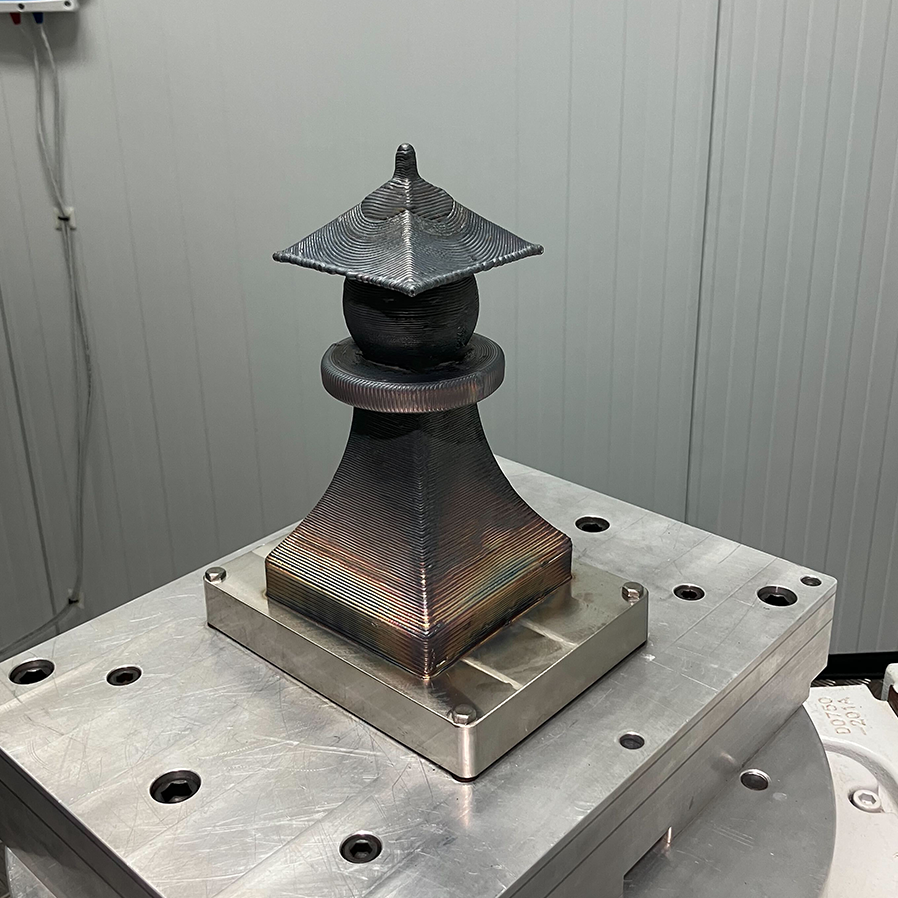

Replacement of cast parts

Eliminating long lead times and costly tooling by directly manufacturing metal parts on demand

New product development

Producing functional prototypes rapidly to support R&D activities and reduce time to market

Tool-less part fabrication

Manufacturing metal components without the need for existing molds or drawings, using reverse engineering or design-from-scratch workflows

Tool-less part fabrication

Manufacturing metal components without the need for existing molds or drawings, using reverse engineering or design-from-scratch workflows

Discontinued product reproduction

Reviving legacy parts where tooling is unavailable or obsolete

Machining jig production

Creating custom jigs in-house to support production and quality assurance processes.

These improvements have positioned Daidore to respond more quickly to customer needs and explore new business opportunities.

Shortened production cycles

Lower operation costs

Greater design freedom

Increased production autonomy

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

System: Meltio Robot Cell

It is designed to provide industries with a secure and efficient solution for manufacturing metal 3D printed parts.

Sector: R&D & Aerospace

Meltio meets Class 1 laser safety standards, ensuring no harmful laser exposure to the operator.

Material: Stainless Steel

Wire feedstock proves more affordable and safer than powder-based alternatives.

Printing Time: 5h 34min

Production time was 3 weeks

Additive manufacturing as a business enabler

Looking ahead, Daidore has outlined a comprehensive strategy to integrate Meltio’s technology more deeply into its operations.

The company plans to:

Scale up prototype production to support a broader range of new product development projects

Expand its use of Meltio for small-lot and custom manufacturing, particularly where traditional methods are uneconomical

Incorporate Meltio into the company’s supply chain operations to streamline order processing and reduce third-party dependencies

In the short term, Daidore’s objective is to enhance its product development capabilities and improve part quality while continuing to master Meltio’s technology.

In the long term, the company aims to use 3D printing as a platform for launching entirely new business models, improve its overall technical know-how, and build a competitive edge rooted in additive manufacturing.

Building long-term growth

Daidore Corporation’s adoption of Meltio’s wire-laser metal AM technology marks a pivotal step in its transition toward a more flexible, efficient, and future-ready manufacturing model. By leveraging the Meltio Robot Cell, the company is not only solving current production challenges but also laying the foundation for innovation, growth, and sustained competitive advantage in the years to come.

Want to know more about printed parts properties?

Want to know more about printed parts properties?