Case study developed by Roez

ROEZ R@D s.r.o., a Czech research and development company, is driven by a mission to boost energy efficiency and promote sustainable resource use, particularly in nuclear, hydro, and petrochemical sectors.

With a focus on creating specialized prototypes and equipment, the company established its advanced technology center “Tokáň” and embraced cutting-edge tools, including Meltio’s wire-laser metal 3D printing solution, to support its green energy initiatives.

Engineering barriers in energy component production

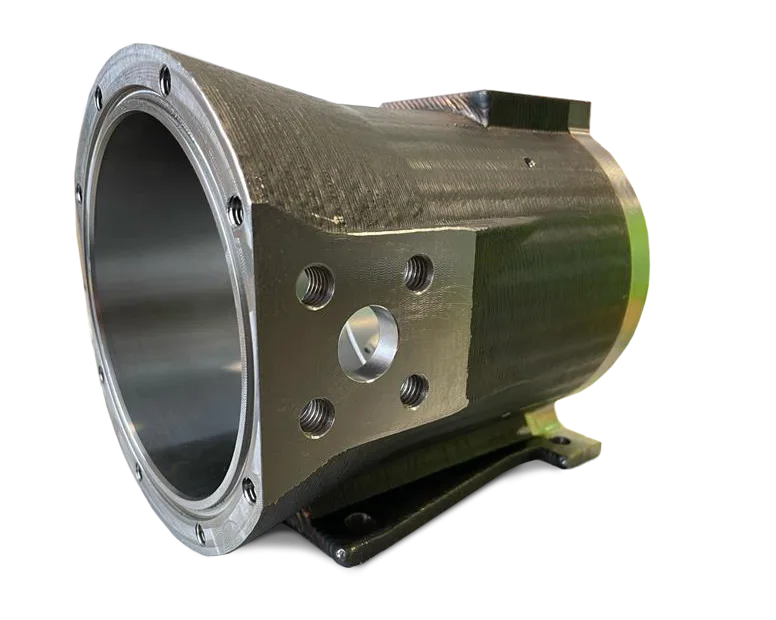

Developing specialized energy components—like turbine cases for low-potential heat recovery—presents significant design and manufacturing challenges. Conventional methods, such as CNC machining and powder-based 3D printing, proved insufficient due to complexity, cost, and material limitations.

ROEZ R@D needed a solution capable of producing complex internal geometries in a single build without extensive post-processing.

A tailored solution for a high-performance application

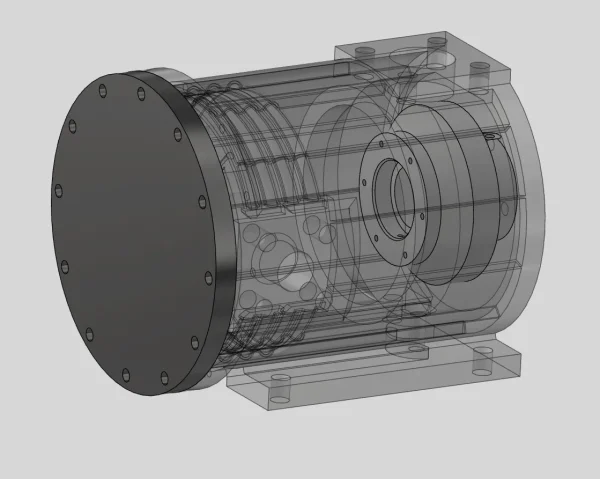

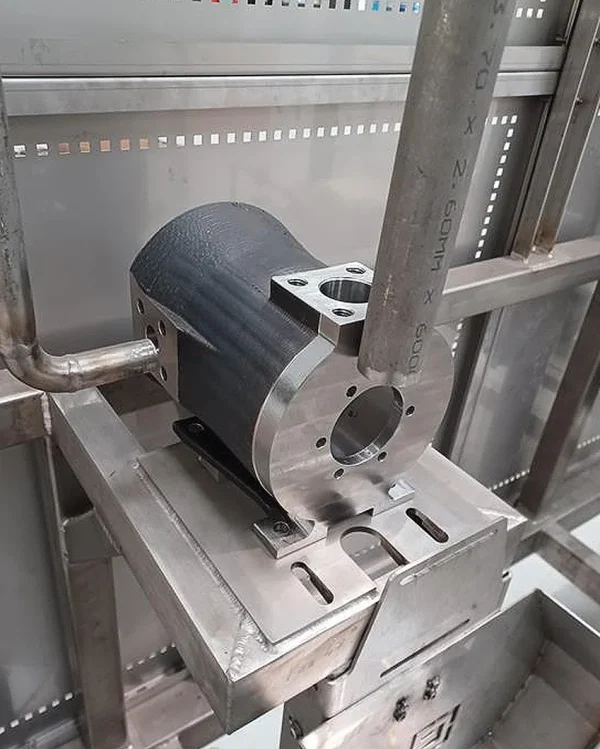

The search for a reliable, flexible, and efficient metal AM solution led ROEZ R@D to the Meltio M450. Unlike powder-based printers or robotic welding setups, the Meltio M450 offered an out-of-the-box, standalone system with minimal infrastructure requirements. It supported a wide range of materials—including stainless steel, titanium, and nickel alloys—and enabled autonomous operation with remote control capabilities.

ROEZ R@D used the Meltio M450 to successfully produce a complex turbine case in a single print, using materials like S316Ls and ER70. The system’s easy-to-use interface, open material platform, and competitive pricing made it a standout choice.

Rapidly prototype and iterate on complex parts without relying on external suppliers

Reduce lead times and costs associated with traditional manufacturing or outsourced 3D printing

Explore advanced materials previously impractical for their applications

Integrate a scalable AM solution into their workflow with minimal disruption

Key features driving Meltio adoption

After evaluating several additive manufacturing technologies—including powder-bed fusion and binder jetting systems—Daidore selected Meltio’s wire-laser metal deposition technology, specifically the Meltio Robot Cell, due to its unique combination of affordability, flexibility, and scalability.

Key features that influenced the decision:

Turnkey metal AM-system

Only out-of-the-box wire-laser printer on the market

Multi-material capability

Wide variety of alloys (S316L, ER70, Ti, Ni-625…) from one machine

Ease of operation & autonomy

Compact, intuitive interface + reliable remote monitoring; minimal human oversight

Single-print complexity

One-piece turbine case with internal flow passages in a single build

No additional infrastructure

No welding/fabrication station required: true plug-and-play

Capital & operating costs

Competitive machine price and wire-only feedstock vs. high custom electrodes and setups

Meltio 3D Printing Solutions

Unlock the potential of metal 3D printing with Meltio. Your journey starts here.

85 hours printing time

Designed for industry without the need for industrial infrastructure; affordable, reliable, safe, and easy to use metal 3D printer.

Wire feedstock proves more affordable and safer than powder-based alternatives.

Shortened production cycles

Lower operation costs

Bulding the future of green manufacturing

While challenges remain, ROEZ R@D’s experience demonstrates that Meltio’s technology can serve as a cornerstone in the transition to a smarter, more sustainable manufacturing. Their journey underscores the potential of wire-laser AM to empower small innovators and reshape the energy sector from the ground up.