On-demand repair and manufacturing

Defense Sector

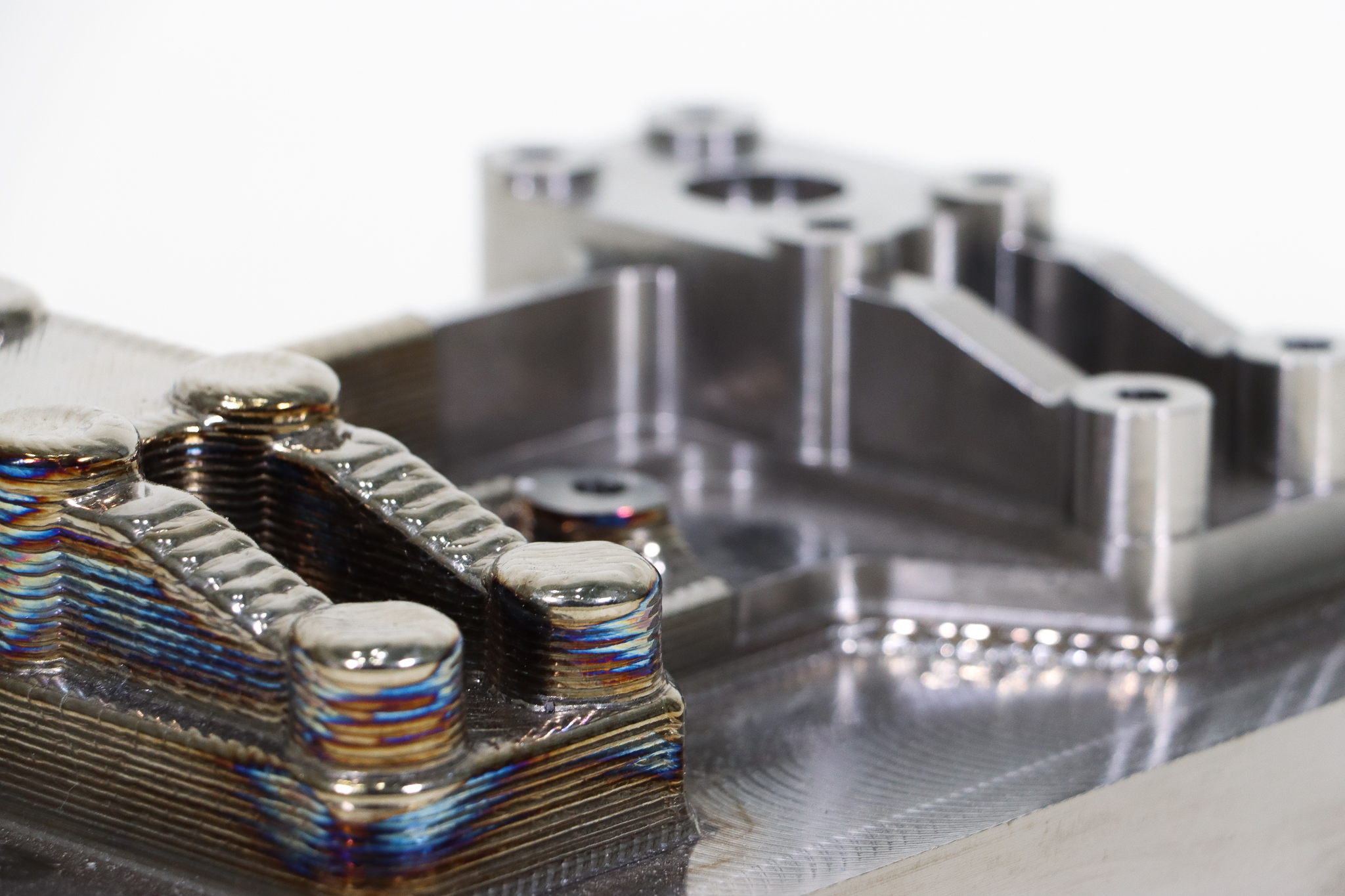

Global supply chain disruptions threaten defense readiness. Meltio provides the solution: on-demand metal part production with autonomous Wire-Laser Metal 3D Printing.

Our technology combines safety, reliability, and easy integration. With Meltio, defense forces now possess viable options to overcome supply chain fragility, extend platform lifecycles, and ensure availability of critical components in contested environments at the point of need.

Enhanced operational readiness

A robust and adaptable solution that optimizes the production, repair and customization of parts, thus strengthening the effectiveness and sustainability of military operations.

Material versatility

Work with a wide range of common military-grade metals. This allows for the production of parts with high strength and density, corrosion resistance, and heat tolerance.

Rapid prototyping & R&D

Rapid iteration on designs, autonomously and with minimal reliance on external providers, accelerating the development cycle for new military hardware.

Parts at the point of use

On-demand repair and manufacturing of critical components and weaponry, minimising the logistical burden of stocking hundreds of spares.

Legacy components

Reduced lead times from weeks to hours by creating replacement parts for legacy systems, ships, and vehicles that manufacturers no longer support.

Sample Parts of Interest

Find the perfect fit for your application.

Brackets

Application sector: Vehicles

Type of application: Spare Parts

Vehicle Spare Pars

Application sector: Vehicles

Type of application: Spare Parts

Broken Gears

Application sector: Automotive/Machinery

Type of application: Repair

Tank Wheels

Application sector: Vehicles

Type of application: Repair

Sample Parts of Interest

Manufacturing of customized components on demand.

Download Meltio’s Brochure for Defense

Download Meltio’s Brochure for Defense

Download Meltio’s Brochure for Defense

United States

Ongoing projects

Ammunition

Funnel

Defense Supplier

– Casting Replacement

– Stainless Steel

– Courtesy of Phillips Corp.

U.S Army

xTech Program

5th place won with proposal:

– Deployable Hybrid System

– Process inert gas available anywhere with nitrogen generators

– Machine reliability

Trusted by

the DoD

Federal Goverment

– Strategic technology partner

– The first hybrid machine was installed in a deployable

shipping container at Rock Island Arsenal in 2021

– By Meltio’s partner, Phillips Corporation

“If the crew had to rely on a replacement part without using additive manufacturing, it would have taken weeks or months. With this technology, we’ll have the new component printed and ready for installation before the order for a replacement would be completed”.

Staff Sgt. Jordan Blake, a member of the Marine Innovation Unit.

USS Arleigh Burke

FDRMC Rota together with the Spanish Navy

– NAVSEA enabled quicker AM part approval by waterfront engineers for low-risk components.

– AM saved over 80% of the typical production time.

– NAVSEA ensures U.S. Navy ships and systems are mission-ready worldwide.

Deployable Hybrid Manufacturing Center

Snowbird

– Reverse Osmosis Pump Bushing

– New part was printed and machined faster

– Saving time, money, space, and increasing overall warfighter readiness

– By Meltio’s partner, Snowbird

“We have empowered and equipped our waterfront and forward-deployed engineers and maintainers that directly support our warfighters. This project executed with our Spanish allies further proves the significant readiness AM generates for our ships, restoring a critical system while meeting the compressed timeline for the ship’s forward-deployed patrol.”

Advancing Defense Manufacturing with Meltio’s Technology

Discover tangible success stories exemplifying how the Defense Sector is benefiting from Meltio

Advancing Defense Manufacturing with Meltio’s Technology

Discover tangible success stories exemplifying how the Defense Sector is benefiting from Meltio

Spain

Ongoing projects

Jet Engine

Repair

Spanish Air Force

– Repair of High Value Parts

– Titanium

– Copper-based Alloys

Armored Vehicle

Spare Parts

Spanish Army

– Spare Parts Manufacturing

– Stainless Steel

“Thanks to these joint actions, the Defense Dpt. will improve the supply and logistics chains of the Armed Forces, increase the operability of fleets, resources in operations and avoid problems related to the obsolescence of parts and pieces, as well as increase their useful life.”

France

Ongoing projects

AM for Land Forces ES

French Army

– Manufacturing Spare Parts

– Prototypes and tooling

– Repairing Spare Parts

– New features

– By Meltio’s partner, Multistation

“The introduction of Meltio’s additive manufacturing (AM) into naval operations supports readiness and self-sufficiency. These printers can help the Navy overcome both obsolescence issues for ships and systems that have service lives measured in decades and directly contribute to enhanced operational availability of our systems and ships.”

Rear Adm. Brendan McLane, commander, Naval Surface Force Atlantic, and NAVSEA Chief Engineer Rear Adm. Jason Lloyd.

South Korea

Ongoing projects

Container Mobility System

Republic of Korea Marine Corps

– Cargo ship Membrane Tank

– Spherical Tanks

– Aerospace components

– By Meltio’s partner, AM Solutions

“It has become possible to quickly manufacture repair parts that are discontinued or difficult to procure.”

Republic of Korea Marine Corps

Download Meltio’s Brochure for Defense

Download Meltio’s Brochure for Defense

Download Meltio’s Brochure for Defense

Advancing Defense Manufacturing with Meltio’s Technology

Discover tangible success stories exemplifying how the Defense Sector is benefiting from Meltio

Advancing Defense Manufacturing with Meltio’s Technology

Discover tangible success stories exemplifying how the Defense Sector is benefiting from Meltio

Do you want to know more?

Contact us!

Receive a tailor-made response within 1 – 2 business days.