Meltio Engine Robot Integration

Large and complex manufacturing

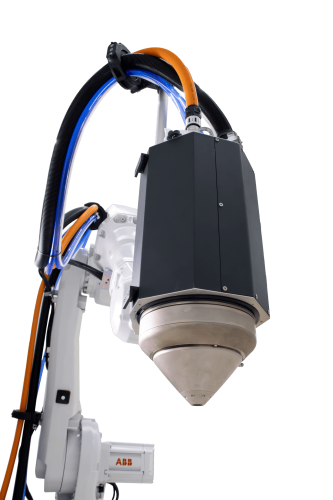

Retrofit any industrial robot arm for large-scale metal additive manufacturing

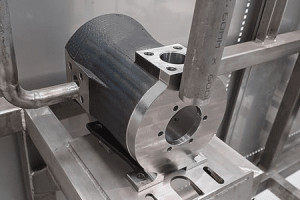

Turn a robot arm into a metal 3D printing system with no inherent size constraints. lt is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

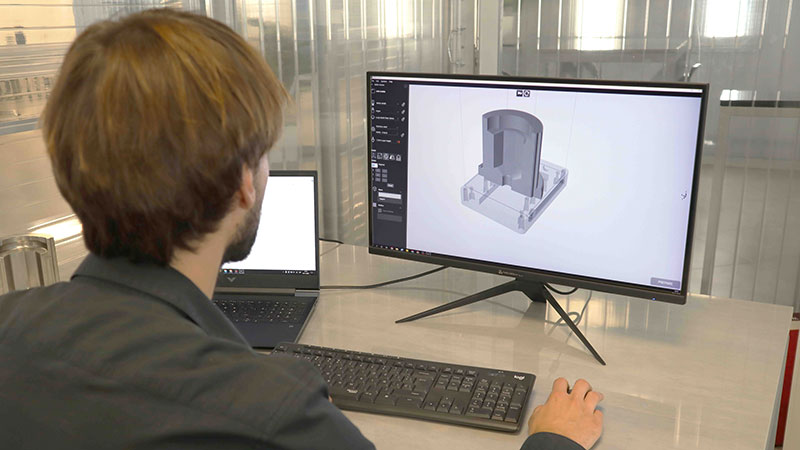

The Meltio Engine integrates with any robot arm manufacturer and interface on the market. Meltio Space slicer software for robots is compatible with ABB, Kuka, Fanuc, Yaskawa and Siemens.

Large-scale

No inherent constraints when the working envelope is only limited by the size of the motion system.

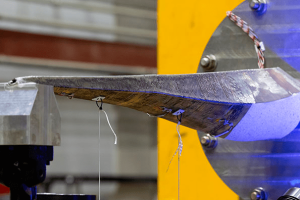

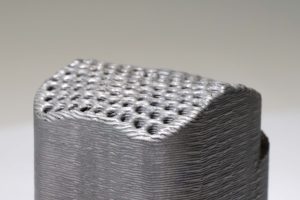

Geometry freedom

Create highly complex parts with infinite degrees of freedom.

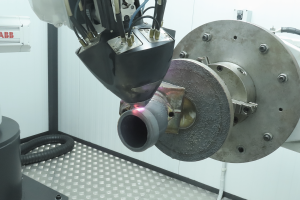

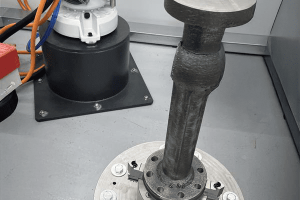

Cladding & Hard-facing

Provide new capabilities to any robot arm by turning it into a metal 3D printing system. Apply wear-resistant coatings to industrial tools, shafts, and molds.

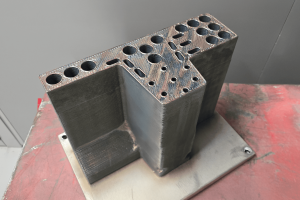

Part repair

Easily solve spare part problems by repairing parts that are no longer produced in any industry.

Technical specifications

Meltio Engine Blue Integration kit

| Laser System: | Blue Laser (Higher absorption and power efficiency; wider range of compatible materials than IR) 1000W 9 x 450 nm direct diode lasers |

|---|---|

| Printhead: | Robot Mounted 20.5 to 23 kg |

| Printhead Size (WxDxH): | 262 x 272 x 572 mm |

| Control Unit: | Wall mounted, air-cooled 80.5 kg 600 x 300 x 800 mm. Separate wall mounted 27″ HMI |

| Cooling: | Water-cooled deposition head. Chiller lncluded |

| Print Envelope (WxDxH): | Depending on robot’s reach |

| Process Control: | Melt Pool Camera & Closed-loop wire modulation |

| Power Input: | 200/240 V 3W+PE 380/415 V 3W+N+PE |

|---|---|

| Power Consumption: | 9,2 kW peak 2-5 kw avg. |

| Slicer Software: | Meltio Space 1-year subscription lncluded |

|---|---|

| Feeder System: | Quad-point traction servomotor feeder, frictionless liners |

| Wire Feedstock: | Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready |

| Product Configurations: | Single or Dual Wire |

| Compatible Materials: | Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium, Copper Alloys, Gold alloys and more |

Meltio Engine IR Integration kit

| Laser System: | Infrarred Laser 1200W 6 x 976 nm direct diode lasers + fibers & colimators |

|---|---|

| Printhead: | 15.5 kg |

| Printhead Size (WxDxH): | 230 x 310 x 710 mm |

| Control Unit: | Floor Mounted (Wheeled) 125 kg with 27″ HMI 390 x 650 x 1600 (deployed screen) |

| Cooling: | Water-cooled control unit and deposition head. Chiller included |

| Print Envelope (WxDxH): | Depending on robot’s reach |

| Process Control: | Closed-loop, wire modulation |

| Power Input: | 200/240 V 3W+PE 380/415 V 3W+N+PE |

|---|---|

| Power Consumption: | 2 – 5 kW peak depending on selected options |

| Slicer Software: | Meltio Space 1-year subscription lncluded |

|---|---|

| Feeder System: | Dual traction stepper motors + External Feeder (Push-pull system), conventional wire liners |

| Wire Feedstock: |

Diameter: 0.8-1.2 mm / Spool Type: 8S300 External wire drum ready |

| Product Configurations: | Single or Dual Wire |

| Compatible Materials: | Stainless Steels, Carbon Steels, Tool Steels, Nickel Alloys, Titanium and more |

Meltio Engine Robot Integration applications

Overcome traditional manufacturing limitations, producing intricate geometries that were previously impossible or too costly to realize.

Do you want to know more about printed part properties?

Customer validation & Success stories

We are using the Meltio Robot Cell to repair high-value mining equipment. By cladding wear-resistant layers onto worn shafts and crushers, we extend the life of heavy machinery by 300% compared to buying new parts.

Integration was seamless. We mounted the Meltio head onto our existing ABB robot arm, transforming a standard handling bot into a flexible metal manufacturing cell without altering our factory floor layout.

We wanted a solution that would allow us to produce large, custom parts internally — without the overhead of tooling, molds, or external delays. Meltio’s technology, combined with robotic freedom, gave us exactly that.

We’ve opened a really unique design space through 3D printing. This project has demonstrated that additive manufacturing has the potential to produce very strong, stiff structures that will be good for marine energy.

Know more about Meltio Engine Robot integration

Optimizing applications with cored wires and exotic materials

Discover how Meltio and Welding Alloys are redefining industrial repair and protection with cutting-edge metal 3d printing and advanced welding solutions.

Get a quote Meltio Engine Robot Integration

Receive a tailor-made offer

Know more about us

Check our latest news and use case