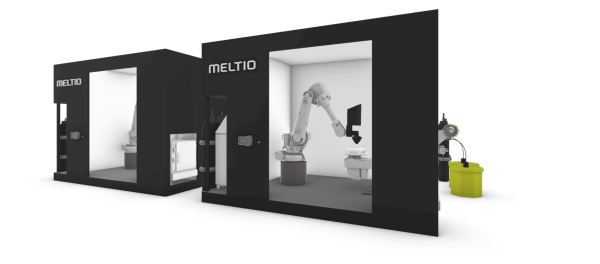

Meltiohas today launched the Meltio Robot Cell, a turn-key metal 3D printing solution to boost the performance of industrial robotic arms in a safer, more reliable, and highly accurate way by controlling the entire process including its recently launched slicing software, Meltio Space.

In its vision as a patented DED 3D printing technology developer and manufacturer to accompany and be the reliable solution for industries around the world to adopt Meltio’s wire-laser metal 3D printing solutions that reduce costs and improve manufacturing processes, the Spanish multinational has today presented a new hardware innovation: the Meltio Robot Cell. This new system allows standard metal 3D printing starting from a build plate in a factory as well as part repair or feature addition.

Meltio Robot Cell works with an open hardware platform that lets Meltio attach its metal 3D deposition head to any brand of robotic arm. In this case, it’s done to improve user experience by introducing a standardization approach through the Meltio Robot Cell.

The volume and work area defined in the Meltio Robot Cell workspace meet all manufacturing needs using our industrial-level additive manufacturing technology to take full advantage of Meltio’s metal 3D printhead and be able to manufacture parts in an industrial environment autonomously thanks to its monitoring and safety features.

The robot and positioner are installed on a self-supporting platform, as well as a laser-safe enclosure together with the Meltio Engine, Meltio Space, and accessories.

With the Meltio Robot Cell, the company is fulfilling most of the applications that industry and integrators need when printing industrial metal parts, and this is the reason this standardization matches with the possibility of building custom integrations with the help of Meltio partners.

The Meltio Robot Cell is designed as a plug-and-play system, with a single electrical power supply and a single inert gas supply. The environmental conditions are standard and this cell cannot be outdoors or unprotected from the sun and dust, it must be in a controlled environment.

This solution allows the customer to receive a product ready to use for robotic metal 3D printing.

The Meltio Robot Cell is certified and tested to operate with an ABB robotic arm as standard configuration and aimed at all industries. It is most certainly an evolution of the Meltio Engine Robot Integration as a base production model to enable industries to incorporate 3D printed parts manufacturing with the Meltio head integrated into a robot into their production systems.

As Meltio Engine Product Manager, Alejandro Nieto is excited about this new innovation:

“Meltio’s main commitment with the launch of the Meltio Robot Cell is to offer all types of industries the ability to manage the entire manufacturing process using our metal 3D printing technology consisting of a Meltio head integrated into a robotic arm and in a safe environment, in order to just produce parts.

This new hardware system allows the customer to receive a ready-to-use cell for robotic metal 3D printing, removing the integration process and long assembly lead times. The Meltio Robot Cell has a specific area for every supply the cell requires on a daily basis, only connecting to the inert gas and electric supply is enough to start manufacturing.

Meltio highlights its ability to boost client productivity and enhance manufacturing capabilities. In 2023, they are offering the Meltio Robot Cell with a lead time of just 4 to 6 weeks.

The Meltio Robot Cell also provides the industrial customer with a working protocol. Relative to existing offerings in the market today, the Meltio Robot Cell is very competitively priced. The cost of the solution is also competitive when compared with thermoplastic and concrete 3D printing systems as seen in other sectors that demand 3D printing for structural parts.

This cell has the possibility to be delivered with other robot brands on the market to be more responsive to customers in terms of availability and technical capability. The Meltio Robot Cell is compatible with the open hardware platform that allows Meltio to integrate our metal 3D printing head on any brand of robotic arms”.

Technical specifications

- Easy to install. Everything is included

- Turn-key solution

- Best-in-class Components

- Safe, Tested, and Certified

- CLASS 1 Laser Product

- Meltio Space 1 (one) year subscription

- Large 3D Printing Volume with Continuous positioner axes interpolation

- Standard CE certification. UCKA in UK and UL in America to be evaluated

- Steel platform with leveling points and wiring ducts

- All equipment and peripherals are anchored on the platform

- All cell controls are unified on a single control panel

- Everything is sent integrated and tested

- The final reseller/integrator focuses work on training and enabling the client to manufacture parts.

- Load and unload from a truck with regular size and load forklift

- Includes 300x400mm actively cooled build platform and buildplates

- Single three-phase connector input

- All cell controls are unified on a single control panel:

- Connected to the customer’s local network (LAN) for PC interconnectivity

- ABB’s SafeMove to avoid collisions with enclosure

- Safe environment for the end customer

- Specific Quality Controls before and after integration, ensuring maximum performance at its final destination.

Upcoming accessories

Inert Bubble: Specific hardware options already implemented in the welding industry to ensure the best results when printing with high oxidizing materials like titanium and related alloys, this can be mandatory in sectors such as Aeronautics and Space.

Final design under development, sizes, pricing, and configurations to be defined. For now, request information on a case-by-case basis for customers in need of certification and/or low oxidation requirements until more information is available.