Lupburg (Germany) & Linares (Spain) – January, 22nd, 2024. Meltio, a disruptive laser metal deposition technology manufacturer, today announced that FIT AG became the first official service bureau and a key contributor to its application development in Germany and the DACH region.

FIT AG is a German industrial Additive Manufacturing integrator aiming to provide accessible and affordable metal 3D printing services to a variety of industries. Their business model enables the widespread use of various additive manufacturing technologies. After verifying the various advantages of Meltio’s state-of-the-art wire laser metal deposition (LMD), FIT AG decided to incorporate this innovative technology into its portfolio.

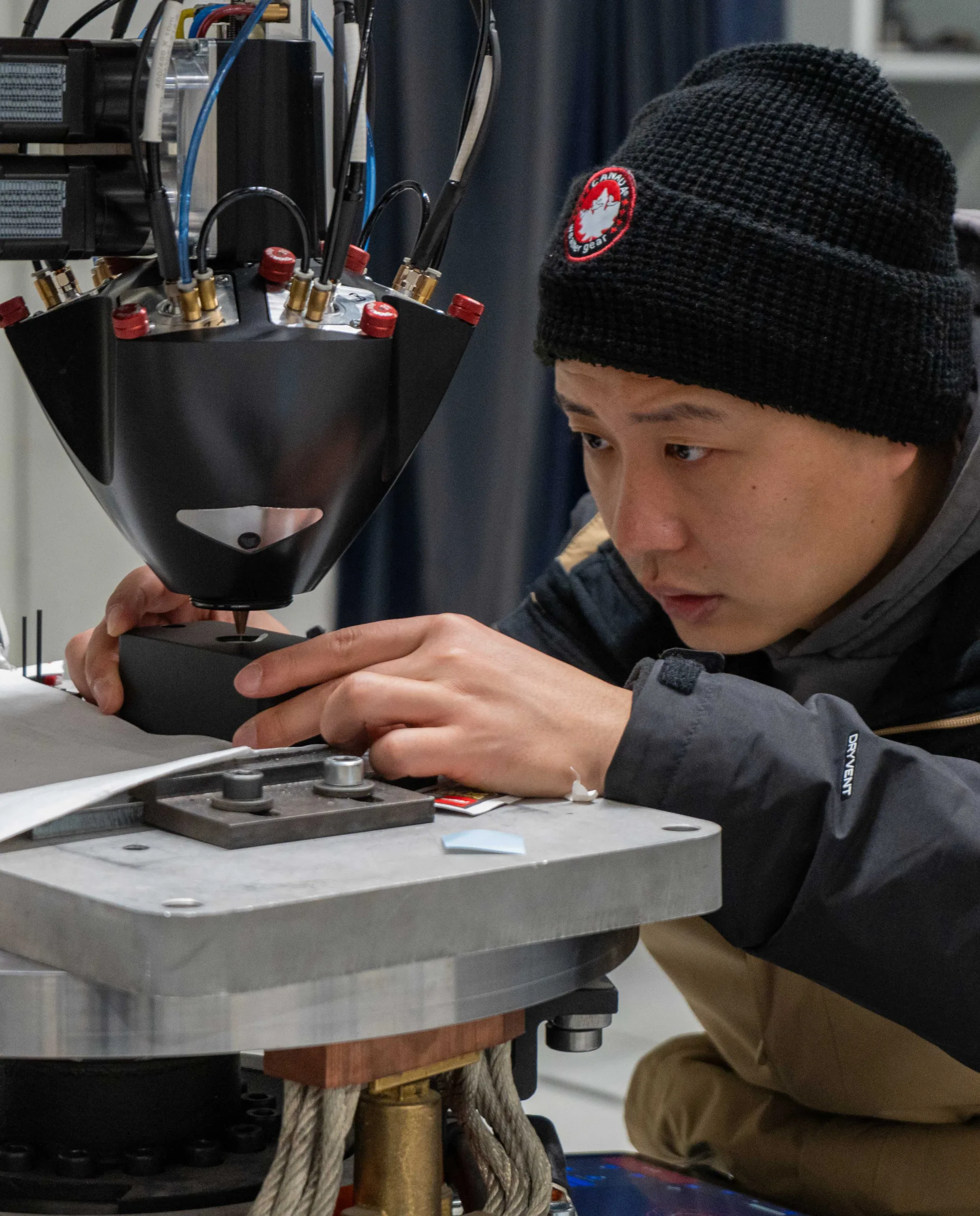

By adding the Meltio Engine integrated into a robotic arm, FIT AG will play a key role in making this technology accessible across the DACH region. They will also assist in the improvement and advancement of said technology. Furthermore, FIT AG will support the demand for Meltio parts for a wide range of applications for industrial sectors.

Meltio’s cutting-edge multi-metal 3D printing technology precisely stacks weld beads on top of one another when introduced into a laser-generated melt pool. The process uses commodity welding wire, the cleanest, safest, and lowest-cost metal feedstock on the market.

The Meltio Engine integrates impeccably with both robotic as well as CNC equipment, bringing new metal additive manufacturing capabilities to a wide range of industries and applications.

“We are thrilled to be working with FIT AG and KnowHow Wilhelms, as this collaboration between us serves as a great indicator of how Meltio’s partner ecosystem is evolving. Together we will be able to cater to the ever-growing interest in Meltio’s technology and its applications.

As well as by leveraging FIT’s knowledge, we will be able to further develop the adoption of Meltio’s unique wire-laser metal additive manufacturing for different industries. – Moisés Moza Sánchez, Sales Manager in DACH region at Meltio.

For FIT, Meltio’s Laser DED technology is the neatly matching missing link between Selective Laser Melting and Wire Arc Additive Manufacturing (WAAM). It jumps in to fill the performance gap whenever metal parts from WAAM are too chunky and laser melting parts too costly.

An important advantage is that the FIT experts can profit from their special know-how in multiaxial tool path programming from WAAM which they have pushed forward over the last few years.

A prior evaluation of a test system provided by Knowhow Wilhelm was highly positive. Carl Fruth, founder, and CEO of FIT AG, announces “the Laser DED wire technology by Meltio is what appears to be an ideal enhancement of our inventory of AM technologies. We see fantastic opportunities here to develop ground-breaking new applications all along with our customers.”

About Meltio

Meltio takes metal additive manufacturing to the next level by developing high-performance, affordable, and easy-to-use metal 3D printing solutions using wire LMD technology. The company’s mission is to delight customers, partners, and employees by pioneering the development of affordable metal 3D printing systems that are reliable, safe, and powerful, continually reinforcing their status as disruptors.

About FIT AG

FIT Additive Manufacturing Group is a leading international industry partner in the field of additive manufacturing. A technology pioneer with over 25 years of experience, the company develops and manufactures prototypes, production tools, 3D-printed spare parts, additively manufactured end-use parts, and series parts as well as works of art from plastic, metal, and construction materials for a rich variety of verticals.

From additive design, engineering, and manufacturing to post-processing and quality control, the AM specialist provides the entire 3D printing value chain. In addition, FIT has numerous conventional processes at its disposal, such as CNC milling, injection molding, vacuum casting, or the processing of elastomers for efficient small batch series production. Group revenue in 2022 was EUR 25 million. Headquartered in the south of Germany, the company currently employs a total of 250 people.

www.fit.technology